- Building Supplies

- Electrical

- Smart Home, Security, Wi-Fi

- TV & Home Theater

- Extension Cords & Surge Protectors

- Electrical Wire & Cable

- Service Entrance Cables

- Primary Wire

- Sprinkler Wire

- Security Cables

- Armored Cable

- Power Cord

- Thermostat Wire

- Network & Data Cables

- XHHW Wire

- Specialty Wire & Cables

- Ground Wire

- Cable & Wire Holders

- Electrical Whips & Whip Kits

- Dual Armored Cable

- Non-Metallic Wire

- Landscape Lighting Cables & Connectors

- UF Wire

- TFFN & THHN Wire

- Speaker Wire

- Submersible Pump Cables

- Cable & Wire Connectors

- Wall Plates & Inserts

- Conduit & Conduit Fittings

- Generators

- Electronics

- Light Sockets & Adapters

- Electrical Outlets & Plugs

- Electrical Testers & Tools

- Batteries

- Fire Safety

- Light Switches & Dimmers

- Electrical Boxes & Covers

- Solar Power

- Doorbells

- Power Distribution & Circuit Protection

- Electrical Tape

- Lawn & Garden

- Garden Hoses & Accessories

- Landscaping & Hardscaping

- Outdoor Tools & Equipment

- Snow Blowers, Parts & Accessories

- Lawn & Garden Hand Tools

- Chainsaws & Pole Saws

- Spreaders & Sprayers

- Power Equipment Combo Kits

- Trimmers & Edgers

- Power Equipment Parts

- Lawn Aerators

- Engine Oil

- Wheelbarrows & Yard Carts

- Pressure Washers

- Snow Plows & Accessories

- Leaf Blowers

- Log Splitters

- Tillers & Cultivators

- Mulchers & Wood Chippers

- Axes & Mauls

- Power Equipment Fuel

- Garden Decor

- Outdoor Fountains

- Ponds

- Weathervanes

- Bird & Wildlife

- Garden Bridges

- Garden Arbors & Trellises

- Garden Fencing

- Well Pump Covers

- Garden Stakes & Shepherds Hooks

- Flags & Banners

- Outdoor Decorative Lanterns

- Garden Statues & Sculptures

- Outdoor Torches & Candles

- Thermometers, Clocks & Gauges

- Garden Stools

- Wind Chimes & Twisters

- Insect & Pest Control

- Pots & Planters

- Grills & Outdoor Cooking

- Irrigation & Outdoor Drainage

- Lawn Mowers

- Plant Care

- Storage & Organization

- Plumbing

- Water Heater Parts & Accessories

- Pipe & Fittings

- CPVC Pipe & Fittings

- Push to Connect Fittings

- Polyethylene Pipe, Fittings & Accessories

- Pipe Support & Clamps

- PEX Pipe, Fittings & Specialty Tools

- Tubing & Hoses

- Sewage Pipe & Fittings

- Structural Pipe & Fittings

- ABS DWV Pipe & Fittings

- Copper Pipe & Fittings

- CSST Pipe & Fittings

- Galvanized Pipe & Fittings

- Brass Fittings

- Pipe Insulation

- Black Pipe & Fittings

- PVC DWV Pipe & Fittings

- PVC Pipe & Fittings

- Water Filtration & Water Softeners

- Supply Lines

- Utility Sinks & Faucets

- Water Pumps & Tanks

- Valves & Valve Repair

- Water Heaters

- Plumbing Parts & Repair

- Augers, Plungers & Drain Openers

- Plumbing Tools & Cements

- Tools

- Air Tools & Compressors

- Hand Tools

- Clamps & Vises

- Hand Saws & Blades

- Taps & Dies

- Cutting & Crimping Tools

- Staple Guns & Riveters

- Multi-Tools

- Pliers & Plier Sets

- Punches & Knockout Punch Sets

- Sockets & Socket Adapters

- Maintenance Tools

- Powder Actuated Tools & Fasteners

- Ratchets & Breaker Bars

- Chisels & Pry Bars

- Mechanics Tool Sets

- Household Tool Sets

- Nut Drivers & Keys

- Files & Planes

- Grease Guns & Fittings

- Wrenches & Wrench Sets

- Hammers

- Screwdrivers

- Levels & Measuring Tools

- Drills & Drivers

- Clothing

- Ladders & Scaffolding

- Power Tools

- Safety

- Tool Storage & Work Benches

- Shop Vacuums & Accessories

- Flashlights

- Welding & Soldering

- Jobsite Radios

- Paint

- Heating & Cooling

- Furnaces & Furnace Accessories

- HVAC Duct & Fittings

- Registers & Grilles

- Thermostats

- Fireplaces & Stoves

- Humidifiers & Dehumidifiers

- Air Conditioners & Fans

- Through Wall Fans

- Whole House Fan Shutters

- Ductless Mini Splits

- Blower Fans

- Portable Air Conditioners

- Evaporative Coolers

- Evaporative Cooler Accessories

- Whole House Fans

- Window Air Conditioners

- Wall Air Conditioners

- Wall Mounted Fans

- Central Air Conditioners

- Air Conditioner Parts & Accessories

- Portable Fans

- Whole House Fan Timers

- Air Filters & Accessories

- Air Purifiers & Accessories

- Portable & Space Heaters

- HVAC Components

- Heat Pumps

- Underfloor Heating

- Heating Fuel Tanks

- Radiator Covers

- Boilers

- Cleaning Supplies

- Hardware

- Cabinet Hardware

- Door Hardware

- Door Latch Hardware

- Door Security

- Closet Door Hardware

- Door Jamb Security & Repair Kits

- Pocket Door Hardware

- Screen & Storm Door Hardware

- Door Knockers

- Deadbolts

- Barn Door Hardware

- Door Sweeps

- Bathtub & Shower Door Hardware

- Sliding Patio Door Hardware

- Screen & Storm Door Handles

- Door Closers

- Door Handles

- Door Knobs

- Door Hinges

- Electronic Door Locks

- Door Kick Plates

- Door Stops

- Handlesets

- Picture Hangers

- Window Hardware

- Metal Rods, Shapes & Sheets

- Specialty Hardware

- Safes

- Furniture Hardware

- Fasteners

- Chains, Ropes & Tie-Downs

- Signs, Letters & Numbers

- Keys & Key Safes

- Locks

- Hooks

- Marine Hardware

- Automotive

- Lighting

- Flooring

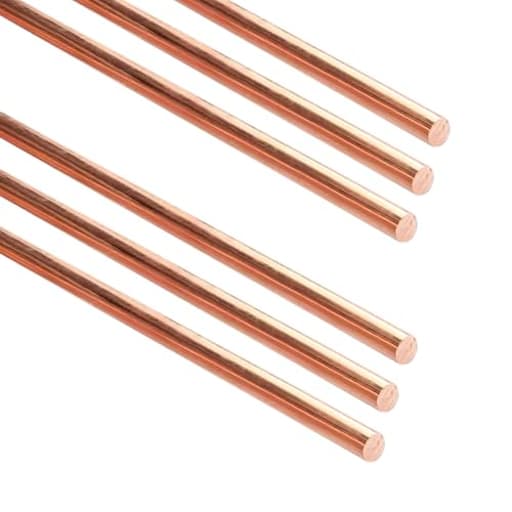

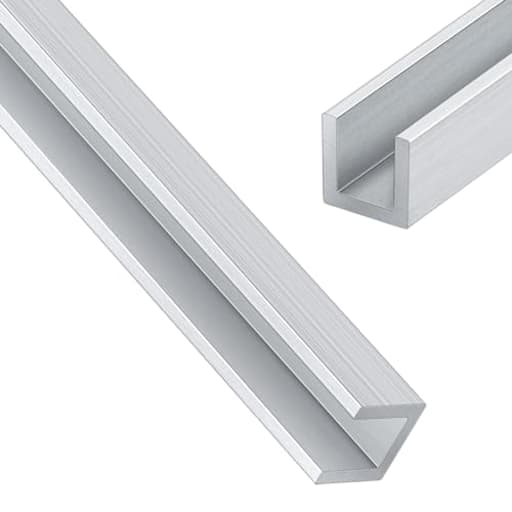

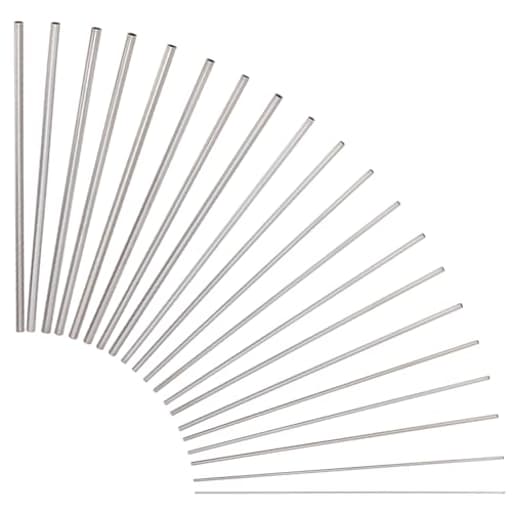

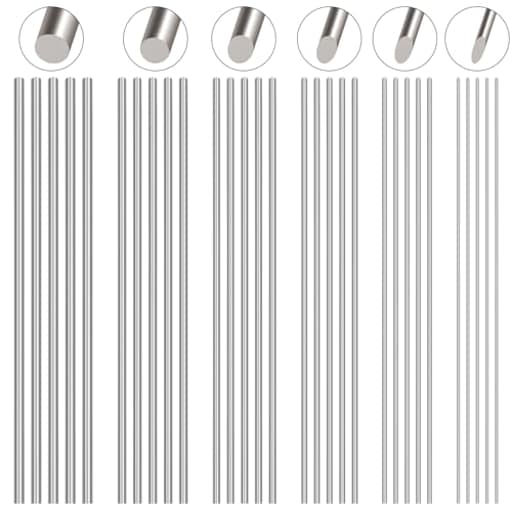

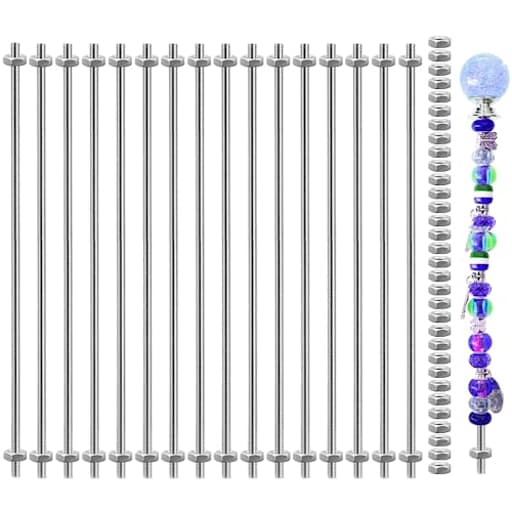

Metal rods, shapes, and sheets form the backbone of metal fabrication, repair, and prototyping. This stock includes round rod, flat bar, angle, channel, tube, pipe, sheet, plate, perforated sheet, and expanded metal in steel, stainless, aluminum, brass, and copper. Choose finishes such as hot rolled, cold rolled, galvanized, or anodized to balance strength, corrosion resistance, machinability, conductivity, weight, and appearance. Selecting the right gauge, thickness, and temper ensures the stiffness and durability your project demands.

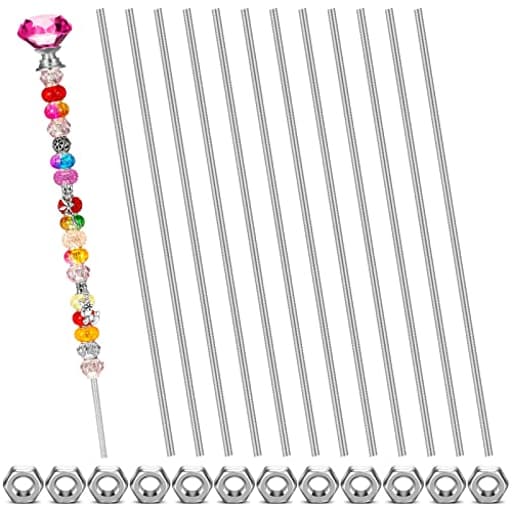

Pick alloys to match the job: 1018 or A36 for general steel work, 304/316 for corrosion resistance and food contact, 12L14 for free‑machining parts, 6061-T6 for strong, lightweight aluminum frames, and 5052 for formable sheet metal. Sheets excel at panels, ducting, guards, and enclosures. Rods become shafts, pins, spacers, and axles. Angles and channels build brackets and frames. Tubes and pipe create rigid, lightweight structures for trailers, furniture, roll cages, and handrails.

Work faster with the right tools: chop saws or band saws for clean cuts, metal shears and aviation snips for thin sheet, angle grinders and flap discs for edge prep, deburring tools, step bits and cobalt drill bits with cutting fluid for holes, and taps and dies for threads. Accurate layouts benefit from calipers, squares, and center punches. Strong joints start with proper fit‑up, clamps, and welding magnets. Always wear gloves, eye protection, and hearing protection.

Buying tips that save time and money:

- Order cut‑to‑length to reduce waste and shipping.

- Check mill tolerance, straightness, and surface finish if parts fit tightly.

- Account for kerf and bend radii in your cut lists.

- Choose galvanizing, powder coat, or anodizing for outdoor longevity.

Find the metal supply that matches your schedule with local pickup, by‑the‑foot pricing, and quick ship options. Ideal for DIY, construction, automotive, HVAC, aerospace, and architectural projects and sculpture.