- Building Supplies

- Electrical

- Smart Home, Security, Wi-Fi

- TV & Home Theater

- Extension Cords & Surge Protectors

- Electrical Wire & Cable

- Service Entrance Cables

- Primary Wire

- Sprinkler Wire

- Security Cables

- Armored Cable

- Power Cord

- Thermostat Wire

- Network & Data Cables

- XHHW Wire

- Specialty Wire & Cables

- Ground Wire

- Cable & Wire Holders

- Electrical Whips & Whip Kits

- Dual Armored Cable

- Non-Metallic Wire

- Landscape Lighting Cables & Connectors

- UF Wire

- TFFN & THHN Wire

- Speaker Wire

- Submersible Pump Cables

- Cable & Wire Connectors

- Wall Plates & Inserts

- Conduit & Conduit Fittings

- Generators

- Electronics

- Light Sockets & Adapters

- Electrical Outlets & Plugs

- Electrical Testers & Tools

- Batteries

- Fire Safety

- Light Switches & Dimmers

- Electrical Boxes & Covers

- Solar Power

- Doorbells

- Power Distribution & Circuit Protection

- Electrical Tape

- Lawn & Garden

- Garden Hoses & Accessories

- Landscaping & Hardscaping

- Outdoor Tools & Equipment

- Snow Blowers, Parts & Accessories

- Lawn & Garden Hand Tools

- Chainsaws & Pole Saws

- Spreaders & Sprayers

- Power Equipment Combo Kits

- Trimmers & Edgers

- Power Equipment Parts

- Lawn Aerators

- Engine Oil

- Wheelbarrows & Yard Carts

- Pressure Washers

- Snow Plows & Accessories

- Leaf Blowers

- Log Splitters

- Tillers & Cultivators

- Mulchers & Wood Chippers

- Axes & Mauls

- Power Equipment Fuel

- Garden Decor

- Outdoor Fountains

- Ponds

- Weathervanes

- Bird & Wildlife

- Garden Bridges

- Garden Arbors & Trellises

- Garden Fencing

- Well Pump Covers

- Garden Stakes & Shepherds Hooks

- Flags & Banners

- Outdoor Decorative Lanterns

- Garden Statues & Sculptures

- Outdoor Torches & Candles

- Thermometers, Clocks & Gauges

- Garden Stools

- Wind Chimes & Twisters

- Insect & Pest Control

- Pots & Planters

- Grills & Outdoor Cooking

- Irrigation & Outdoor Drainage

- Lawn Mowers

- Plant Care

- Storage & Organization

- Plumbing

- Water Heater Parts & Accessories

- Pipe & Fittings

- CPVC Pipe & Fittings

- Push to Connect Fittings

- Polyethylene Pipe, Fittings & Accessories

- Pipe Support & Clamps

- PEX Pipe, Fittings & Specialty Tools

- Tubing & Hoses

- Sewage Pipe & Fittings

- Structural Pipe & Fittings

- ABS DWV Pipe & Fittings

- Copper Pipe & Fittings

- CSST Pipe & Fittings

- Galvanized Pipe & Fittings

- Brass Fittings

- Pipe Insulation

- Black Pipe & Fittings

- PVC DWV Pipe & Fittings

- PVC Pipe & Fittings

- Water Filtration & Water Softeners

- Supply Lines

- Utility Sinks & Faucets

- Water Pumps & Tanks

- Valves & Valve Repair

- Water Heaters

- Plumbing Parts & Repair

- Augers, Plungers & Drain Openers

- Plumbing Tools & Cements

- Tools

- Air Tools & Compressors

- Hand Tools

- Clamps & Vises

- Hand Saws & Blades

- Taps & Dies

- Cutting & Crimping Tools

- Staple Guns & Riveters

- Multi-Tools

- Pliers & Plier Sets

- Punches & Knockout Punch Sets

- Sockets & Socket Adapters

- Maintenance Tools

- Powder Actuated Tools & Fasteners

- Ratchets & Breaker Bars

- Chisels & Pry Bars

- Mechanics Tool Sets

- Household Tool Sets

- Nut Drivers & Keys

- Files & Planes

- Grease Guns & Fittings

- Wrenches & Wrench Sets

- Hammers

- Screwdrivers

- Levels & Measuring Tools

- Drills & Drivers

- Clothing

- Ladders & Scaffolding

- Power Tools

- Safety

- Tool Storage & Work Benches

- Shop Vacuums & Accessories

- Flashlights

- Welding & Soldering

- Jobsite Radios

- Paint

- Heating & Cooling

- Furnaces & Furnace Accessories

- HVAC Duct & Fittings

- Registers & Grilles

- Thermostats

- Fireplaces & Stoves

- Humidifiers & Dehumidifiers

- Air Conditioners & Fans

- Through Wall Fans

- Whole House Fan Shutters

- Ductless Mini Splits

- Blower Fans

- Portable Air Conditioners

- Evaporative Coolers

- Evaporative Cooler Accessories

- Whole House Fans

- Window Air Conditioners

- Wall Air Conditioners

- Wall Mounted Fans

- Central Air Conditioners

- Air Conditioner Parts & Accessories

- Portable Fans

- Whole House Fan Timers

- Air Filters & Accessories

- Air Purifiers & Accessories

- Portable & Space Heaters

- HVAC Components

- Heat Pumps

- Underfloor Heating

- Heating Fuel Tanks

- Radiator Covers

- Boilers

- Cleaning Supplies

- Hardware

- Cabinet Hardware

- Door Hardware

- Door Latch Hardware

- Door Security

- Closet Door Hardware

- Door Jamb Security & Repair Kits

- Pocket Door Hardware

- Screen & Storm Door Hardware

- Door Knockers

- Deadbolts

- Barn Door Hardware

- Door Sweeps

- Bathtub & Shower Door Hardware

- Sliding Patio Door Hardware

- Screen & Storm Door Handles

- Door Closers

- Door Handles

- Door Knobs

- Door Hinges

- Electronic Door Locks

- Door Kick Plates

- Door Stops

- Handlesets

- Picture Hangers

- Window Hardware

- Metal Rods, Shapes & Sheets

- Specialty Hardware

- Safes

- Furniture Hardware

- Fasteners

- Chains, Ropes & Tie-Downs

- Signs, Letters & Numbers

- Keys & Key Safes

- Locks

- Hooks

- Marine Hardware

- Automotive

- Lighting

- Flooring

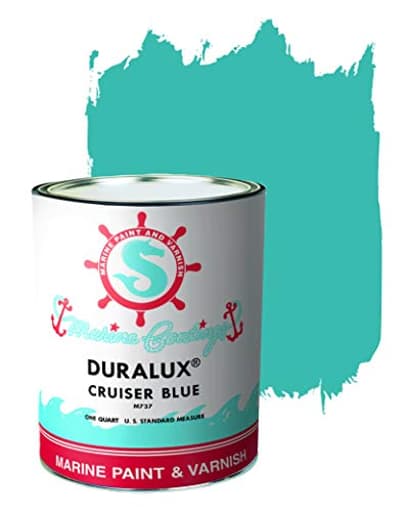

Marine paint protects boats, yachts, sailboats, powerboats, and commercial vessels in harsh conditions. Quality boat paint resists saltwater and freshwater, UV, chemicals, and abrasion, preventing corrosion, osmosis blisters, and marine growth. A properly coated hull and topsides look sharp, run smoother, and may cut fuel use. The result is better performance, easier cleaning, and longer service life at the dock, on the trailer, or offshore.

- Antifouling bottom paint: ablative, hard, and hybrid formulas—copper-based or copper-free—to fight barnacles and slime, maintain hull speed, and extend time between haul-outs.

- Topside and deck paint: high-gloss polyurethane and enamel systems for color and UV retention; non-skid deck coatings with grit additives for safe footing.

- Primers and barrier coats: epoxy primers and moisture barriers for fiberglass, plus corrosion control for aluminum and steel hulls.

- Bilge and locker paint: tough, solvent- and fuel-resistant finishes for easy cleanup in wet spaces.

- Specialty coatings: waterline and boot stripe enamels, non-skid additives, prop and running gear coatings, and aluminum-safe bottom paints for outboards and pontoon boats.

Choose marine coatings by substrate (fiberglass, aluminum, steel, or wood), compatibility with existing paint, fouling pressure in your waters, and how the boat is used—moored full-time or trailered. Consider local regulations and low-VOC, copper-free options. Check coverage rates, dry and recoat times, launch windows, and temperature and humidity limits to plan the job right.

Preparation drives results: de-wax, degrease, sand, fair, and wipe clean before priming and painting. Apply with roller and brush “roll and tip,” or spray where permitted. Follow film thickness guidance, mix thoroughly, and use the correct thinner. Wear PPE and ensure ventilation. Respect cure schedules for strong adhesion and blister protection.

Inspect coatings seasonally, scrub growth promptly, touch up scrapes, and track recoat intervals. Store cans sealed and stirred for the next project. Keep records of products and dates.