Features

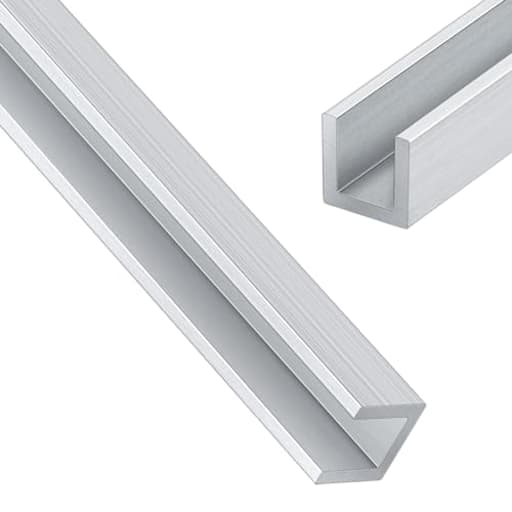

- Reliable Quality: with quality aluminum alloy as its fundamental material, these aluminum C channels exemplify nice reliability and resilience; Unaffected by elements such as rust and corrosion, its infallible quality ensures a sturdy and long lasting performance, providing impact protection; Ensuring high resistance against deformity, it offers an environment for substrates and circuit boards

- Ideal Dimensions for Many Applications: with an inside width of 1/4", wall thickness of 1/16", height and outer width of 3/8", total length of 4 ft for versatile usage; These dimensions make the the C channel metal ideal for a variety of applications such as creating display stands, edge guards for posters, sign frames, and more

- Beneficial Package: the package comes with 1 piece of aluminum channel; The U channel can help decrease the sagging or bending of your shelving when properly installed, offering a robust and sturdy finish

- Please Note: the U channel aluminum offers users the flexibility to adjust accordingly if the channel fit is loose or imperfect; Simply add tape (not included) to the edges of the substrate or circuit board for a snug fit

- Easy Installation: with our simple, user friendly design, installing is a breeze, saving you time and energy; No need to sand or file rough edges or unfinished edges; Quick and easy to install

Specifications

| Unit Count | 1 |

Related Tools

A 4 ft aluminum U-channel (6063-T6) with a 1/4" inside width, 1/16" wall thickness and 3/8" height/outer width, designed for edge trim and support in posters, sign frames, display stands and similar applications. Extruded aluminum resists rust and corrosion, helps reduce sagging when installed, and the single-piece package can be adjusted for a snug fit using tape if necessary.

Yaocom 1 Pcs 4 ft 1/4" U Channel Aluminum 1/16" Walls x 3/8" High x 3/8" Width Aluminum C Channel Metal 6063 Alloy T-6 Temper for Posters Signs Frame Display Stands Review

A versatile 1/4-inch U-channel that earns its keep

I reach for aluminum U-channel anytime I need a clean edge, a simple track, or a way to tame a floppy panel. This 4-foot, 1/4-inch inside-width aluminum U-channel from Yaocom has become one of those shop staples I’m happy to keep on hand. Over several weeks I used it three ways: as a bottom track for a small sliding panel, as edge protection on a poster frame, and as a snug guide for a 6 mm acrylic insert. Across all those tasks it cut, fit, and installed without drama, which is exactly what I want from a basic extrusion.

What you get and how it measures up

This is a 6063-T6 aluminum U-channel with a 1/4-inch (0.250") inside width, 1/16-inch (0.0625") wall thickness, and 3/8-inch outer height/width. The 4-foot length arrived straight, with a clean mill finish and no dents. On my calipers, the inside width stayed very consistent along the length—mine hovered around 0.252–0.253 inches—which is ideal: it accepts true 1/4-inch stock and 6 mm acrylic (about 0.236") without binding, while leaving just a touch of clearance. For undersized “quarter-inch” plywood (often 0.20–0.22 inches), you’ll want to shim; a wrap or two of high-quality tape on the panel edges is a quick fix that works well.

The walls are thin enough to keep weight down but thick enough to resist casual bending when used as a cap, track, or trim. Extrusion seams were unobtrusive, edges were surprisingly clean out of the box, and I found no burrs that would snag material during dry fits.

Workability: easy to cut, drill, and finish

6063-T6 is an easy-working, architectural-grade alloy, and that shows here. I crosscut the channel on a miter saw with a non-ferrous blade, taped the cut line to protect the finish, and got clean, square ends. A few strokes with a fine file broke the edges. Drilling and countersinking were straightforward with standard bits; the material doesn’t grab or clog if you keep the chips clearing. If you’re attaching the channel with screws, #4–#6 pan heads sit nicely; for flush fasteners, a light countersink in the outer leg is all it takes.

If you’re mitering corners for a frame, the 1/16-inch walls are forgiving—cuts meet cleanly with minimal deflection—but do support the legs with a scrap block to avoid crushing when clamping. Adhesives also work well; construction adhesive or a thin bead of epoxy holds to wood and the mill finish just fine. Degrease first for best results.

Installation notes that saved me time

As a sliding track: A 3/8 x 3/8-inch routed groove accepts the channel perfectly for a flush, recessed track. I used the channel as the bottom guide for a lightweight sliding door; movement was noticeably smoother than the same panel riding in a raw wood dado. For a silky glide, a strip of UHMW tape inside the channel is an inexpensive upgrade.

As edge guard: On a poster frame, the channel capped the 1/4-inch backer board and doubled as a stiffener. It gave the assembly a square, finished look and reduced flex along the long edge.

For acrylic panels: 6 mm acrylic slides in with a little play; a single wrap of painter’s tape on the acrylic edge created a rattle-free fit. For a permanent insert, a thin bead of clear silicone works as both shim and adhesive.

Fastening options: If the channel will see side loads, screws through the outer leg into the substrate are more secure than relying on friction alone. Pre-drill to avoid distorting the profile.

Safety tip: Edges are not knife-sharp, but they’re crisp. A quick pass with a deburring tool or sandpaper is worth the minute it takes.

Stiffness and strength in practice

It bears saying: this is a light-duty U-channel. In 6063-T6 with 1/16-inch walls, it’s ideal for guiding, capping, and edge protection, and it does a respectable job as a localized stiffener on thin panels. On a 24-inch span of 1/4-inch MDF, capping the front edge with this channel noticeably reduced sag under a few pounds of distributed load. But don’t treat it like a structural beam—if you need serious rigidity, look to thicker-wall channel or a different profile (angle, rectangular tube) in 6061-T6 or heavier gauges.

For outdoor use, raw 6063 forms a protective oxide and holds up well to weather. In coastal or abrasive environments I’d clear-coat or paint it, or choose anodized channel if cosmetics matter long-term. Indoors, the mill finish resists fingerprints and cleans easily.

Fit, tolerance, and surface finish

If your project depends on a truly snug, rattle-free fit with 1/4-inch nominal materials, remember that many sheet goods run undersized. In my tests:

1/4-inch acrylic (cast or extruded) varies; 6 mm acrylic fits with a touch of play that’s easy to tune out with tape or a thin felt strip.

1/4-inch plywood is commonly undersized; plan on shimming.

1/4-inch aluminum plate fits true-to-size and may require a light wax for sliding applications.

Surface-wise, you’re getting a standard mill finish—fine extrusion lines, uniform appearance, and no coating. It looks clean enough for display applications as-is. If you want a brushed aesthetic, a Scotch-Brite pad evens the grain in a few passes. For high-touch installations, consider a clear lacquer to ward off fingerprints and scuffs.

Where it shines

- Sliding guides for lightweight doors, panels, or drawers

- Edge protection and stiffening for posters, signs, and thin panels

- Simple frames for 1/4-inch substrates

- Tracks for removable acrylic or polycarbonate inserts

- Quick jigs, fences, and layout channels on shop tables

I also had good luck routing a shallow groove into a workbench top and insetting a short length as a fabric cutting guide; the aluminum lip provides a crisp reference that won’t wear like wood.

Limitations to keep in mind

- Light-duty only: not the right profile or wall thickness for heavy loads.

- Single length: 4 feet is generous for small projects but can force a splice on larger runs. It would be nice to see multi-packs or longer options.

- Raw aluminum: great for most uses, but if you need a premium look out of the box, anodized channel would save finishing steps.

- Conductive: if you’re using this to hold circuit boards, insulate the contact points to prevent shorts.

None of these are deal-breakers; they’re simply realities of a thin-wall architectural extrusion.

Value and alternatives

Within the world of 1/4-inch U-channel, this piece hits the sweet spot of straightness, workable tolerance, and ease of installation. If your project demands tighter tolerance or a different finish, anodized or thicker-wall options exist—but they come at a higher cost and often in larger minimum quantities. For general shop and DIY use, this channel does exactly what it promises with minimal fuss.

The bottom line

The Yaocom aluminum U-channel is the kind of humble, well-executed component that makes small projects go smoothly. It arrived straight, measured consistently, cut cleanly, and installed without surprises. The 6063-T6 alloy provides enough stiffness for light duty, the 1/16-inch walls keep the profile clean and unobtrusive, and the dimensions play nicely with the materials most of us reach for around the shop.

Recommendation: I recommend this U-channel for anyone needing a reliable 1/4-inch track, trim, or edge guard for light- to medium-duty projects. It’s easy to work with, dimensionally consistent, and versatile across wood, acrylic, and composite applications. If you need heavy structural reinforcement or a pre-finished, showpiece look, choose a thicker or anodized alternative; otherwise, this is a solid, no-nonsense choice that earns a spot in the material rack.

Project Ideas

Business

Custom Slim Frame Product Line

Sell ready-to-ship slim poster frames using pre-cut U-channel rails plus backing boards and hanging hardware. Offer standard sizes (A2, A3, 24x36"), optional acrylic front, and printing/packaging upsells. Low material cost and compact shipping make this a high-margin ecommerce product for art prints, posters, and certificates.

DIY Sign Mounting Kits for Small Business

Assemble and sell kits containing pre-cut channel lengths, adhesive foam strips or screws, corner caps, and simple instructions for mounting storefront or window signs. Target contractors, cafes, and craft fair vendors who need a quick, professional reinforcement to prevent sign sagging. Offer white-label or branded kits for local sign shops.

Portable Trade-show Display Hardware

Design a lightweight modular connector system using short U-channel sections as rails and brackets to build collapsible banner stands and display frames. Market to small businesses and freelancers who attend events. Emphasize durability (6063‑T6 alloy) and easy assembly; sell replacement rails and carry cases as add-ons.

Educational Craft/Sub kit Subscription

Create monthly classroom or maker kits that use aluminum U-channels for projects (nameplates, mini-shelves, signage). Each kit includes pre-cut channels, safe cutters, adhesives, and lesson plans. Sell subscriptions to teachers and makerspaces; highlight safety (thin walls, no rust) and reusable metal parts for repeated lessons.

Sign Reinforcement & Retrofit Service

Offer a local service to retrofit existing posters, foamboard displays, and small signs with aluminum U-channel reinforcement to eliminate sagging and extend service life. Target galleries, restaurants, realtors, and event organizers. Charge per linear foot plus travel/installation; provide bulk discounts for chains and recurring maintenance contracts.

Creative

Slim Poster Frame

Create minimalist, snap-together poster frames by cutting the 4 ft U-channel into top and bottom rails sized to your poster. Slip the poster edge into the 1/4" channel, back with thin foamboard or cardboard, and secure with a few dabs of double‑sided tape. Finish with a sawtooth hanger or adhesive picture hanger. Result: lightweight, rustproof frames that give posters a clean, modern edge.

Acrylic Sign Edge Trim

Use the channel as an edge trim for acrylic nameplates or small signs. Slide a laser-cut acrylic panel into the channel for a polished metal border and improved rigidity. Add clear silicone or tape inside the channel for a snug fit. This is great for door signs, desk nameplates, or LED edge-lit signs when paired with thin LED strips.

Thin Floating Shelf Lip

Build shallow floating shelves for small items by mounting the channel with the open side up to a plywood strip or acrylic shelf. The channel becomes a front lip that prevents items from sliding off and stiffens the shelf to reduce sag. Paint or anodize the plywood face to match decor; use anchors for wall installation.

Cable Tidy Raceway

Convert the channel into an under‑desk cable channel: cut to length, mount with adhesive tape or small screws (through pilot holes), tuck cables into the 1/4" slot, and conceal with a thin removable cover (vinyl or scrap acrylic). It’s a low‑profile, metal cable management solution that resists deformation.

Gallery Rail for Lightweight Prints

Mount continuous strips of the channel along walls as a low-profile hanging rail for lightweight prints and posters. Use picture wire, clips, or small acrylic hooks that slot into the channel edge. The aluminum rail is corrosion-resistant and prevents sagging over long runs — ideal for rotating displays at home or small pop-up galleries.