- Building Supplies

- Electrical

- Smart Home, Security, Wi-Fi

- TV & Home Theater

- Extension Cords & Surge Protectors

- Electrical Wire & Cable

- Service Entrance Cables

- Primary Wire

- Sprinkler Wire

- Security Cables

- Armored Cable

- Power Cord

- Thermostat Wire

- Network & Data Cables

- XHHW Wire

- Specialty Wire & Cables

- Ground Wire

- Cable & Wire Holders

- Electrical Whips & Whip Kits

- Dual Armored Cable

- Non-Metallic Wire

- Landscape Lighting Cables & Connectors

- UF Wire

- TFFN & THHN Wire

- Speaker Wire

- Submersible Pump Cables

- Cable & Wire Connectors

- Wall Plates & Inserts

- Conduit & Conduit Fittings

- Generators

- Electronics

- Light Sockets & Adapters

- Electrical Outlets & Plugs

- Electrical Testers & Tools

- Batteries

- Fire Safety

- Light Switches & Dimmers

- Electrical Boxes & Covers

- Solar Power

- Doorbells

- Power Distribution & Circuit Protection

- Electrical Tape

- Lawn & Garden

- Garden Hoses & Accessories

- Landscaping & Hardscaping

- Outdoor Tools & Equipment

- Snow Blowers, Parts & Accessories

- Lawn & Garden Hand Tools

- Chainsaws & Pole Saws

- Spreaders & Sprayers

- Power Equipment Combo Kits

- Trimmers & Edgers

- Power Equipment Parts

- Lawn Aerators

- Engine Oil

- Wheelbarrows & Yard Carts

- Pressure Washers

- Snow Plows & Accessories

- Leaf Blowers

- Log Splitters

- Tillers & Cultivators

- Mulchers & Wood Chippers

- Axes & Mauls

- Power Equipment Fuel

- Garden Decor

- Outdoor Fountains

- Ponds

- Weathervanes

- Bird & Wildlife

- Garden Bridges

- Garden Arbors & Trellises

- Garden Fencing

- Well Pump Covers

- Garden Stakes & Shepherds Hooks

- Flags & Banners

- Outdoor Decorative Lanterns

- Garden Statues & Sculptures

- Outdoor Torches & Candles

- Thermometers, Clocks & Gauges

- Garden Stools

- Wind Chimes & Twisters

- Insect & Pest Control

- Pots & Planters

- Grills & Outdoor Cooking

- Irrigation & Outdoor Drainage

- Lawn Mowers

- Plant Care

- Storage & Organization

- Plumbing

- Water Heater Parts & Accessories

- Pipe & Fittings

- CPVC Pipe & Fittings

- Push to Connect Fittings

- Polyethylene Pipe, Fittings & Accessories

- Pipe Support & Clamps

- PEX Pipe, Fittings & Specialty Tools

- Tubing & Hoses

- Sewage Pipe & Fittings

- Structural Pipe & Fittings

- ABS DWV Pipe & Fittings

- Copper Pipe & Fittings

- CSST Pipe & Fittings

- Galvanized Pipe & Fittings

- Brass Fittings

- Pipe Insulation

- Black Pipe & Fittings

- PVC DWV Pipe & Fittings

- PVC Pipe & Fittings

- Water Filtration & Water Softeners

- Supply Lines

- Utility Sinks & Faucets

- Water Pumps & Tanks

- Valves & Valve Repair

- Water Heaters

- Plumbing Parts & Repair

- Augers, Plungers & Drain Openers

- Plumbing Tools & Cements

- Tools

- Air Tools & Compressors

- Hand Tools

- Clamps & Vises

- Hand Saws & Blades

- Taps & Dies

- Cutting & Crimping Tools

- Staple Guns & Riveters

- Multi-Tools

- Pliers & Plier Sets

- Punches & Knockout Punch Sets

- Sockets & Socket Adapters

- Maintenance Tools

- Powder Actuated Tools & Fasteners

- Ratchets & Breaker Bars

- Chisels & Pry Bars

- Mechanics Tool Sets

- Household Tool Sets

- Nut Drivers & Keys

- Files & Planes

- Grease Guns & Fittings

- Wrenches & Wrench Sets

- Hammers

- Screwdrivers

- Levels & Measuring Tools

- Drills & Drivers

- Clothing

- Ladders & Scaffolding

- Power Tools

- Safety

- Tool Storage & Work Benches

- Shop Vacuums & Accessories

- Flashlights

- Welding & Soldering

- Jobsite Radios

- Paint

- Heating & Cooling

- Furnaces & Furnace Accessories

- HVAC Duct & Fittings

- Registers & Grilles

- Thermostats

- Fireplaces & Stoves

- Humidifiers & Dehumidifiers

- Air Conditioners & Fans

- Through Wall Fans

- Whole House Fan Shutters

- Ductless Mini Splits

- Blower Fans

- Portable Air Conditioners

- Evaporative Coolers

- Evaporative Cooler Accessories

- Whole House Fans

- Window Air Conditioners

- Wall Air Conditioners

- Wall Mounted Fans

- Central Air Conditioners

- Air Conditioner Parts & Accessories

- Portable Fans

- Whole House Fan Timers

- Air Filters & Accessories

- Air Purifiers & Accessories

- Portable & Space Heaters

- HVAC Components

- Heat Pumps

- Underfloor Heating

- Heating Fuel Tanks

- Radiator Covers

- Boilers

- Cleaning Supplies

- Hardware

- Cabinet Hardware

- Door Hardware

- Door Latch Hardware

- Door Security

- Closet Door Hardware

- Door Jamb Security & Repair Kits

- Pocket Door Hardware

- Screen & Storm Door Hardware

- Door Knockers

- Deadbolts

- Barn Door Hardware

- Door Sweeps

- Bathtub & Shower Door Hardware

- Sliding Patio Door Hardware

- Screen & Storm Door Handles

- Door Closers

- Door Handles

- Door Knobs

- Door Hinges

- Electronic Door Locks

- Door Kick Plates

- Door Stops

- Handlesets

- Picture Hangers

- Window Hardware

- Metal Rods, Shapes & Sheets

- Specialty Hardware

- Safes

- Furniture Hardware

- Fasteners

- Chains, Ropes & Tie-Downs

- Signs, Letters & Numbers

- Keys & Key Safes

- Locks

- Hooks

- Marine Hardware

- Automotive

- Lighting

- Flooring

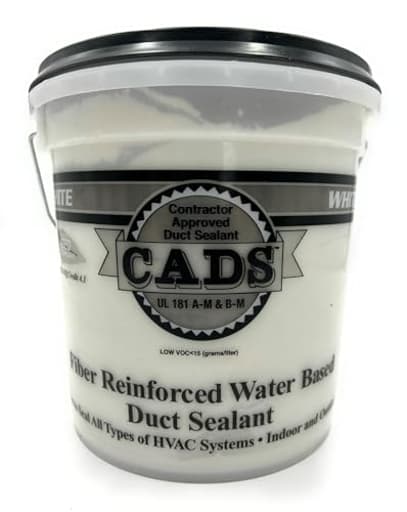

Duct sealants stop air leaks in residential and commercial HVAC ductwork, boosting comfort, efficiency, and indoor air quality. Use them to seal seams and joints at takeoffs, boots, elbows, plenums, and transitions on metal, flexible, and fiberglass ducts. Proper air sealing cuts energy waste, evens out room temperatures, reduces noise and dust, and helps prevent condensation that can lead to mold or corrosion.

Common product types include water‑based duct mastic (brush, trowel, or spray applied), solvent or silicone sealants for high moisture exposure, and UL 181‑rated foil tapes for quick closures. Look for UL 181 A‑M or B‑M mastics for rigid or flex ducts, and UL 181 A‑P or B‑FX for pressure‑sensitive tapes. For outdoor equipment and rooftop curbs, choose UV‑resistant, fiber‑reinforced, and weatherproof formulas.

Key specs to compare:

- Service temperature and pressure class (low, medium, or high pressure systems)

- Adhesion to galvanized steel, aluminum, PVC, and duct board

- VOC content and odor during cure (low‑VOC options support occupied buildings)

- Fire/smoke ratings, mold resistance, and paintability

- Cure time, sag resistance, and clean‑up method

Application tips:

- Clean and dry surfaces; remove oil, dust, and loose insulation.

- Apply a continuous 1/16–1/8 in layer; embed fiberglass mesh over gaps larger than 1/4 in.

- Seal before insulating to avoid trapped moisture; allow full cure before pressure testing.

- Use brushes, notched trowels, or cartridges for control; spray mastic speeds large jobs.

- Verify closures with a duct blaster or smoke pencil to meet IECC and IMC code targets.

Choosing the right HVAC duct sealant reduces utility bills, protects equipment, and extends duct life. Whether you are sealing a new install or tightening an older system, quality mastic and approved tapes deliver durable, code‑compliant results that keep conditioned air where it belongs. Save energy and improve comfort.