- Building Supplies

- Electrical

- Smart Home, Security, Wi-Fi

- TV & Home Theater

- Extension Cords & Surge Protectors

- Electrical Wire & Cable

- Service Entrance Cables

- Primary Wire

- Sprinkler Wire

- Security Cables

- Armored Cable

- Power Cord

- Thermostat Wire

- Network & Data Cables

- XHHW Wire

- Specialty Wire & Cables

- Ground Wire

- Cable & Wire Holders

- Electrical Whips & Whip Kits

- Dual Armored Cable

- Non-Metallic Wire

- Landscape Lighting Cables & Connectors

- UF Wire

- TFFN & THHN Wire

- Speaker Wire

- Submersible Pump Cables

- Cable & Wire Connectors

- Wall Plates & Inserts

- Conduit & Conduit Fittings

- Generators

- Electronics

- Light Sockets & Adapters

- Electrical Outlets & Plugs

- Electrical Testers & Tools

- Batteries

- Fire Safety

- Light Switches & Dimmers

- Electrical Boxes & Covers

- Solar Power

- Doorbells

- Power Distribution & Circuit Protection

- Electrical Tape

- Lawn & Garden

- Garden Hoses & Accessories

- Landscaping & Hardscaping

- Outdoor Tools & Equipment

- Snow Blowers, Parts & Accessories

- Lawn & Garden Hand Tools

- Chainsaws & Pole Saws

- Spreaders & Sprayers

- Power Equipment Combo Kits

- Trimmers & Edgers

- Power Equipment Parts

- Lawn Aerators

- Engine Oil

- Wheelbarrows & Yard Carts

- Pressure Washers

- Snow Plows & Accessories

- Leaf Blowers

- Log Splitters

- Tillers & Cultivators

- Mulchers & Wood Chippers

- Axes & Mauls

- Power Equipment Fuel

- Garden Decor

- Outdoor Fountains

- Ponds

- Weathervanes

- Bird & Wildlife

- Garden Bridges

- Garden Arbors & Trellises

- Garden Fencing

- Well Pump Covers

- Garden Stakes & Shepherds Hooks

- Flags & Banners

- Outdoor Decorative Lanterns

- Garden Statues & Sculptures

- Outdoor Torches & Candles

- Thermometers, Clocks & Gauges

- Garden Stools

- Wind Chimes & Twisters

- Insect & Pest Control

- Pots & Planters

- Grills & Outdoor Cooking

- Irrigation & Outdoor Drainage

- Lawn Mowers

- Plant Care

- Storage & Organization

- Plumbing

- Water Heater Parts & Accessories

- Pipe & Fittings

- CPVC Pipe & Fittings

- Push to Connect Fittings

- Polyethylene Pipe, Fittings & Accessories

- Pipe Support & Clamps

- PEX Pipe, Fittings & Specialty Tools

- Tubing & Hoses

- Sewage Pipe & Fittings

- Structural Pipe & Fittings

- ABS DWV Pipe & Fittings

- Copper Pipe & Fittings

- CSST Pipe & Fittings

- Galvanized Pipe & Fittings

- Brass Fittings

- Pipe Insulation

- Black Pipe & Fittings

- PVC DWV Pipe & Fittings

- PVC Pipe & Fittings

- Water Filtration & Water Softeners

- Supply Lines

- Utility Sinks & Faucets

- Water Pumps & Tanks

- Valves & Valve Repair

- Water Heaters

- Plumbing Parts & Repair

- Augers, Plungers & Drain Openers

- Plumbing Tools & Cements

- Tools

- Air Tools & Compressors

- Hand Tools

- Clamps & Vises

- Hand Saws & Blades

- Taps & Dies

- Cutting & Crimping Tools

- Staple Guns & Riveters

- Multi-Tools

- Pliers & Plier Sets

- Punches & Knockout Punch Sets

- Sockets & Socket Adapters

- Maintenance Tools

- Powder Actuated Tools & Fasteners

- Ratchets & Breaker Bars

- Chisels & Pry Bars

- Mechanics Tool Sets

- Household Tool Sets

- Nut Drivers & Keys

- Files & Planes

- Grease Guns & Fittings

- Wrenches & Wrench Sets

- Hammers

- Screwdrivers

- Levels & Measuring Tools

- Drills & Drivers

- Clothing

- Ladders & Scaffolding

- Power Tools

- Safety

- Tool Storage & Work Benches

- Shop Vacuums & Accessories

- Flashlights

- Welding & Soldering

- Jobsite Radios

- Paint

- Heating & Cooling

- Furnaces & Furnace Accessories

- HVAC Duct & Fittings

- Registers & Grilles

- Thermostats

- Fireplaces & Stoves

- Humidifiers & Dehumidifiers

- Air Conditioners & Fans

- Through Wall Fans

- Whole House Fan Shutters

- Ductless Mini Splits

- Blower Fans

- Portable Air Conditioners

- Evaporative Coolers

- Evaporative Cooler Accessories

- Whole House Fans

- Window Air Conditioners

- Wall Air Conditioners

- Wall Mounted Fans

- Central Air Conditioners

- Air Conditioner Parts & Accessories

- Portable Fans

- Whole House Fan Timers

- Air Filters & Accessories

- Air Purifiers & Accessories

- Portable & Space Heaters

- HVAC Components

- Heat Pumps

- Underfloor Heating

- Heating Fuel Tanks

- Radiator Covers

- Boilers

- Cleaning Supplies

- Hardware

- Cabinet Hardware

- Door Hardware

- Door Latch Hardware

- Door Security

- Closet Door Hardware

- Door Jamb Security & Repair Kits

- Pocket Door Hardware

- Screen & Storm Door Hardware

- Door Knockers

- Deadbolts

- Barn Door Hardware

- Door Sweeps

- Bathtub & Shower Door Hardware

- Sliding Patio Door Hardware

- Screen & Storm Door Handles

- Door Closers

- Door Handles

- Door Knobs

- Door Hinges

- Electronic Door Locks

- Door Kick Plates

- Door Stops

- Handlesets

- Picture Hangers

- Window Hardware

- Metal Rods, Shapes & Sheets

- Specialty Hardware

- Safes

- Furniture Hardware

- Fasteners

- Chains, Ropes & Tie-Downs

- Signs, Letters & Numbers

- Keys & Key Safes

- Locks

- Hooks

- Marine Hardware

- Automotive

- Lighting

- Flooring

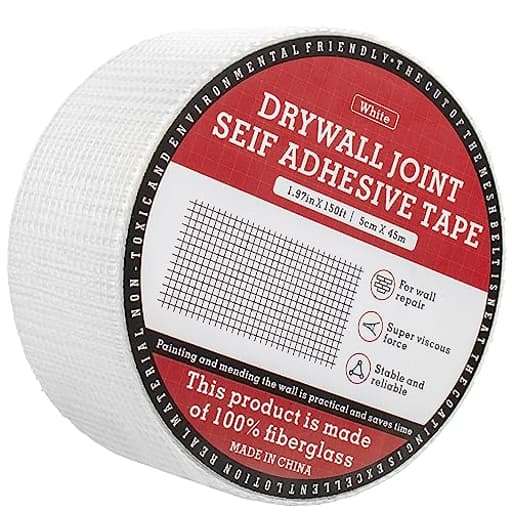

Drywall tape creates strong, smooth joints that disappear under paint. It bridges seams, strengthens inside corners, and helps joint compound cure into a flat, durable surface. For new drywall installs, remodels, and quick patches, the right tape improves speed, reduces cracking, and delivers a pro finish. From paper joint tape to self-adhesive mesh, today’s options serve different tasks and environments.

- Paper joint tape: Creased for corners, high tensile strength, best for butt joints and long seams; works with ready-mix or setting-type compound.

- Fiberglass mesh tape: Self-adhesive for fast application and patching; pair with setting-type compound to limit cracking over butt joints and repairs.

- Metal or composite corner tapes: Rigid edges for straight, impact-resistant corners in high-traffic areas; speeds installation over traditional methods.

- Mold- and moisture-resistant tapes: Suited for baths, kitchens, and basements; helps maintain bond in humid conditions.

Application tips: clean dust, countersink fasteners, and prefill gaps over 1/8 in. For paper, spread a bed coat, embed, and wipe out bubbles with a 4–6 in knife; finish with 8–12 in passes to feather. For mesh, press firmly and embed immediately with setting-type compound. Fold the crease for inside corners, let each coat dry or set, sand lightly, then prime. Most drywall tape measures 1-7/8 to 2 in wide and comes in 75–500 ft rolls—choose longer rolls for large jobs. Store tape dry and flat. Pair tape with a mud pan, taping knives, a corner tool, and sanding blocks or a pole sander for efficient drywall finishing.

Choosing drywall tape based on joint type, environment, and compound saves time and prevents call-backs. Explore drywall tape, drywall joint tape, gypsum board seams, seam repair, and drywall repair supplies to get consistent, paint-ready results on walls and ceilings.