Features

- Premium material: The metal rods is made of high hardness 304 stainless steel, it has the characteristics of high temperature resistance, corrosion resistance, and rust prevention, and has strong processing ability.

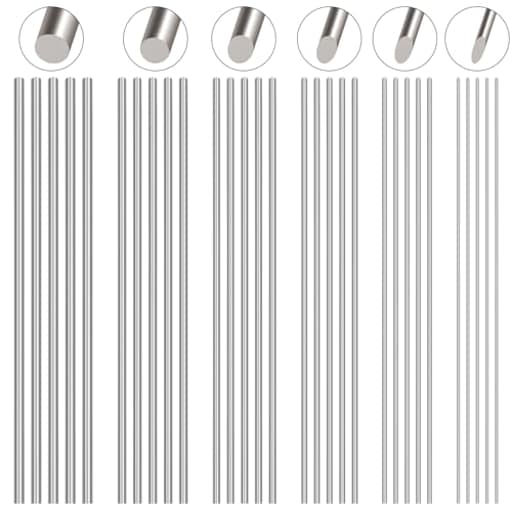

- Size: This stainless steel round metal rod comes in 6 sizes. Size 1: 1 x 100 mm (0.04 x 3.93 inch) ; Size 2: 1.5 x 100 mm (0.06 x 3.93 inch) ; Size 3: 2 x 100 mm (0.08 x 3.93 inch) ; Size 4: 2.5 x 100 mm (0.1 x 3.93 inch) ; Size 5: 3 x 100 mm (0.12 x 3.93 inch); Size 6: 4 x 100 mm (0.16 x 3.93 inch).

- Performance: The surface of round rod steel is smooth, the toughness of the steel is good, it is easy to form, and there are no cracks. It can keep the model stable and running normally.

- Application: The metal rod is widely used in gear shafts, motor shafts, short support shafts, shaft bag models, miniature shafts, model aircraft, helicopters, ships, vehicles, etc.

- Package contents: 30 Pcs 304 stainless steel round rod, 6 sizes. Sufficient quantity and diverse sizes, providing you with more possibilities.

Specifications

| Unit Count | 30 |

Related Tools

30 solid 304 stainless steel round rods, each 100 mm long, supplied in six diameters: 1, 1.5, 2, 2.5, 3 and 4 mm. The rods have a smooth finish, high hardness and good toughness with corrosion and heat resistance, and are suitable for use as shafts, supports, axles and general metalworking or model-making components.

CKANDAY 30 Pcs 6 Sizes 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm x Length 100mm (3.93 Inch) 304 Stainless Steel Round Rod, Metal Rod, Metal Solid Shaft Rods for Industry, Metal Working Hobbies and DIY Craft Review

A small bin of short stainless rods solves more workshop problems than you’d think. The CKANDAY stainless rod assortment isn’t flashy, but after a few weeks of using it for repairs, jigs, and hobby builds, it’s earned a permanent spot on my bench.

What’s in the kit

You get 30 solid 304 stainless steel rods, each 100 mm long, in six diameters: 1, 1.5, 2, 2.5, 3, and 4 mm. That spread covers most of the light-duty shafts, spacers, and pins I need on a typical project. The uniform 100 mm length keeps planning simple—long enough for small mechanisms and fixtures, short enough to fit in compact cases and organizers.

Fit, finish, and first impressions

Out of the pack, the rods were clean, bright, and free of oil or heavy scale. Surface finish is smooth—not mirror-polished—but appropriate for general-purpose use. A few showed faint longitudinal marks from drawing, which is normal for 304 rod stock. Ends were square and usable as-is; I still hit them with a file for a tiny chamfer before pressing into parts.

Straightness was solid across the board. I roll-tested samples on a granite plate and didn’t see any obvious wobble over their 100 mm length. That’s more than sufficient for model gear shafts, hinges, and light-duty axles.

Dimensional consistency was also good. My calipers read the diameters right where they should be, and repeatability across pieces of the same size was tight enough for hobby tolerances. These aren’t precision-ground dowel pins, but for general fitting, slip fits, or light press fits, they behaved predictably.

Working with the material

304 stainless has strengths and quirks. It’s tough, corrosion-resistant, and resilient. It’s also a bit gummy to machine compared to free-machining alloys like 303 or carbon steels like 12L14. The CKANDAY rods behaved as I’d expect from 304:

- Sawing: Hand hacksaw, bandsaw, and rotary cutoff wheels all worked fine. Keep the blade sharp and let it cut—don’t rush or you’ll heat and work-harden the material.

- Drilling: Use sharp cobalt or carbide bits, cutting fluid, slower spindle speeds, and steady feed. Peck drilling helps. If you feather the feed and rub, you’ll work-harden the surface and make life harder.

- Turning and facing: On the lathe, light depth-of-cut with sharp tooling and coolant gives a decent finish. Don’t expect mirror finishes without fussing with speed, feed, and lubrication.

- Tapping and threading: It threads, but the metal’s toughness is noticeable. A quality tap, proper lube, and frequent chip clearing are key. For small threads, I prefer to undersize the pilot hole slightly less than I would for free-machining steel and go slow.

For press fits, a light chamfer on both parts and a touch of oil made assembly smooth. For rotating shafts, pairing these rods with polymer bushings or sintered bronze bearings worked well. I’d avoid using them as bearing races or load-bearing hardened shafts—this is not hardened, precision-ground shafting.

How they performed in projects

- RC and hobby shafts: The 3 and 4 mm rods make quick replacements for small axles and motor shafts in light-duty applications. Concentricity was good enough to avoid vibration at modest RPMs.

- Shop fixtures and jigs: The 2 and 2.5 mm sizes worked nicely as indexing pins and temporary alignment dowels. They pressed into printed or machined blocks cleanly with a predictable fit.

- Spacers and standoffs: Cutting to length and deburring produced tidy spacers that won’t rust in the shop. For non-critical standoffs, these are convenient.

- Small mechanisms: The 1 and 1.5 mm rods are handy for linkages and hinge pins in models or prototypes. I like having multiples of each size on hand so I’m not rationing during a build.

The common thread: predictable behavior. Once I dialed in my cutting and drilling approach, each rod acted like the last—no mysterious soft spots or odd hard patches.

Corrosion resistance and magnetism

In a damp garage and on a garden jig, the rods shrugged off moisture and fingerprints better than mild steel. No rust showed up after a few weeks of casual exposure. That’s the main reason to keep 304 on hand: a “fit-and-forget” material for general duty parts that won’t stain or pit quickly.

On magnetism: several rods exhibited a slight magnetic response. That’s not unusual—304 can become weakly magnetic from cold working during drawing and forming. If your use case demands strictly non-magnetic stainless (think sensitive instruments), assume these will have some attraction and plan accordingly. For everyday projects, the slight magnetism is a non-issue; corrosion resistance is what matters here, and that’s intact.

Accuracy vs. precision

It’s worth setting expectations. This assortment is great for “accurate enough” work: consistent diameters, decent straightness, and a smooth finish suitable for general fits. If you need tightly toleranced, hardened, or centerless-ground rod for linear bearings or high-speed spindles, look to precision shafting or dowel pins instead. For the price of an assorted kit, you’re getting reliable stock, not metrology-grade components.

Practical tips

- Cut long, finish short: Leave an extra millimeter when sawing, then file or face to final length for clean edges and accurate dimensions.

- Deburr both ends: A small chamfer dramatically improves assembly and reduces bushing wear.

- Avoid work hardening: Sharp tools, steady feeds, and cutting fluid will keep the material cooperative.

- Plan for clearance: For running fits with printed or bored holes, test with offcuts and tune hole sizes—surface finish and material springiness affect the feel.

- Label leftovers: Keep offcuts by size. Short sections make excellent pins and spacers.

Where it fits in the shop

This kit is ideal for:

- Hobbyists building models, RC vehicles, robotics, and fixtures

- Repair work where corrosion resistance matters

- Prototyping jigs and quick alignment pins

- Educational and maker spaces that need a variety of small-diameter rods

It’s less ideal for:

- Precision motion systems that require hardened, ground shafting

- High-load axles or wear-critical rotating parts

- Applications that require completely non-magnetic stainless

Value and alternatives

The main value is convenience: multiple diameters, ready to go, without buying full-length bars you may never finish. If your work centers on a single common size, buying dedicated bars in that diameter might be cheaper per part. If you machine stainless frequently and want easier cuts, 303 rod is friendlier at the lathe and drill press—though it trades some corrosion resistance. For press-fit pins with tight tolerance, hardened dowel pins in metric sizes remain the gold standard.

Still, as a general-purpose bin filler, this assortment hits a sweet spot. I reach for it because it saves time, and the pieces are consistent enough that I can trust the results.

The bottom line

The CKANDAY stainless rod assortment delivers exactly what most small shops and hobby benches need: clean, consistent 304 rods in useful sizes that cut, drill, and assemble predictably. They’re not precision-ground or hardened, and a faint magnetic response is present on some pieces, but for light-duty shafts, pins, spacers, and quick fixes, they perform well and resist corrosion as promised.

Recommendation: I recommend this kit to hobbyists, makers, and anyone who wants a ready supply of short stainless rods in common diameters. It’s a practical, good-value assortment for everyday projects. If your work demands non-magnetic stainless, hardened shafts, or tight bearing tolerances, consider specialized stock instead. For the rest of us, this is a handy, dependable standby that earns its drawer space.

Project Ideas

Business

Hobbyist axle & repair kits (Etsy/Shopify)

Package pre-cut, sized axles with matching bushings and instructions as replacement/upgrade kits for modelers (cars, boats, trains, helicopters). Offer variant packs (by diameter) and sell as affordable repair kits to hobby shops or directly to enthusiasts online.

Minimal stainless jewelry line

Design a small collection of minimalist jewelry (stackable rings, bar necklaces, ear studs) using the rods as the primary material. Emphasize durability and hypoallergenic stainless steel, offer polishing/finish options, and sell via an online store or marketplaces with product photos and short how-it’s-made stories.

Maker supply bundle + video tutorials

Create curated starter bundles (e.g., 'miniatures kit', 'jewelry kit', 'toolmaking kit') that include assorted rod diameters, small fasteners and step-by-step project guides or access to short instructional videos. Market to makers, schools and craft groups; monetize both the physical kits and the tutorial content.

Micro-precision parts service for RC & drones

Offer a small-batch machining/finishing service producing custom axles, shafts and alignment pins from supplied stainless rods. Target local hobby shops and drone/RC owners needing hard-to-find or custom-length replacement parts. Add value with quick turnaround and heat/finish options.

Workshops & paid classes

Run in-person or online workshops teaching ring forming, tiny-tool making or kinetic sculpture using these rods. Sell workshop kits beforehand (rods + basic supplies) and upsell finished pieces or custom-cut rod packs. Workshops build credibility and create repeat customers for supplies.

Creative

Miniature axle & wheel kits

Use 1–3 mm rods as axles for model cars, boats and trains. Cut to custom lengths, press-fit or glue small plastic/wood wheels (drill a hole slightly smaller than the rod for a tight fit), add tiny brass or nylon bushings for smooth rotation, and polish the ends. Good for scratch-built RC parts or replacing broken shafts in vintage models.

Ring mandrel + forged ring set

Use the 3–4 mm rods as compact mandrels and shaping forms for making narrow metal or wire rings and band accents. Clamp a rod in a vise and form wire, sheet or thin tubing around it to size, then hammer/texturize and finish. The stainless mandrels are heat and corrosion resistant, so they’re durable for repeated use.

Minimalist mobiles & wind chimes

Build lightweight geometric mobiles or small outdoor wind chimes using 2–4 mm rods as arms and hangers. The smooth stainless finish gives a modern look and resists weather. Thread beads, metal discs or driftwood pieces on the rods, bend ends for hang loops, and counterbalance for kinetic motion.

Tiny jewelry components & posts

Fabricate ear posts, studs, bar pendants, and bracelet spacers from 1–2.5 mm rods. Cut and file ends to size, texture or hammer for visual interest, and solder or epoxy to findings. Their corrosion resistance makes for hypoallergenic, durable minimalist pieces.

Precision jigs, pins & punches

Make small workshop tools: alignment pins, drill guides, center punches, dowel pins or mandrels for jewelry forming. Grind or file tips to shape, heat-treat if needed, and use the rods as repeatable locating features in jigs and fixtures for consistent DIY/micro-machining work.