Features

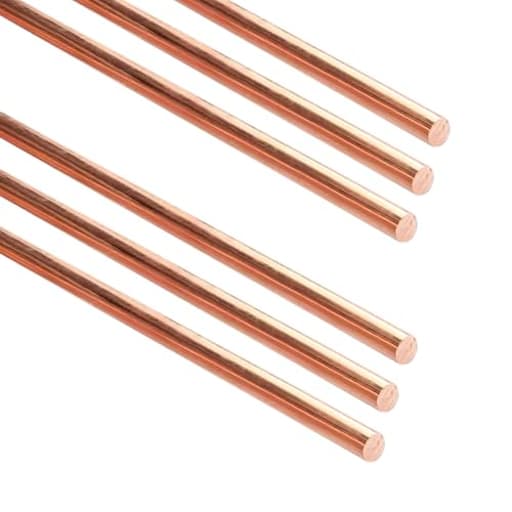

- 【Size】Dia:1/8"(3mm),Length: 12" (305mm),6 Pcs

- 【Characteristic】Copper round bar is made of pure copper(C110) with a copper content of 99.9%.pure Copper Smooth surface without burr,has a metallic luster Ideal for Metal Craft Hobbies DIY

- 【Applications】Copper Cu metal rod excellent electrical conductivity and thermal conductivity,are also suitable for cutting and modeling,metal processing,machinery industry,cable and wire,communication equipment,electronics industry and so on

- 【Notice】The Copper Rod is measured in metric system,please confirm before purchase.

Specifications

| Color | Reddish-Brown |

| Size | 1/8"Dia |

| Unit Count | 6 |

Related Tools

Six 12-inch (305 mm) solid copper round rods, 1/8" (3 mm) diameter, manufactured from C110 copper with approximately 99.9% copper content. They have a smooth, burr-free finish and offer high electrical and thermal conductivity for metalworking, machining, model making, and electrical or electronic applications.

DIYDIYSHOP 12-Inch Length Pure Copper Round Rod 1/8" Dia(3mm),99.9% Solid Copper Rod,Used for Metal Working and Metal DIY Process Review

Why I keep these 1/8-inch copper rods within arm’s reach

A good copper rod is something I reach for more often than I expect: quick bus bars in a prototype, a small RF loop, a custom pin or heat spreader. This six-pack of 1/8-inch copper rods from DIYDIYSHOP has lived on my bench for a few weeks, and I’ve cut, bent, soldered, and machined them enough to know where they shine and where they don’t.

What’s in the pack

You get six solid copper rods, each 12 inches (305 mm) long, listed as 1/8 inch (3 mm) diameter and made from C110 copper (about 99.9% copper content). In practice, the rods I received measured right at 3.00 mm with a micrometer, which matters if you’re planning a precision press fit or mating with true 1/8-inch hardware (3.175 mm). Treat these as metric 3 mm stock and you’ll be happier.

Fit and finish

Out of the box, the rods were straight enough to roll cleanly on a flat surface with only the slightest wobble—well within what I expect for hobby and light fabrication work. The surface is smooth and uniform, with a clean, reddish-brown metallic luster and no burrs or ragged ends. I did see a trace of handling oxidation on one piece, which wiped off with a Scotch-Brite pad in seconds, leaving a bright finish ready for solder.

Workability: cutting, drilling, and light machining

C110 copper is conductive and soft, which is exactly what you want for electrical and thermal work and a mixed bag for machining. Cutting by hand with a fine-tooth hacksaw is quick; a rotary tool with a thin cutoff wheel is even cleaner. I avoid small pipe cutters on rod this size because they tend to flare the ends. Deburring is trivial with a file.

On the drill press, copper can grab; sharp split-point bits, a rigid setup, and low-to-moderate spindle speed help. I drilled several cross-holes (1.5–3.0 mm) for terminal screws without wandering. On a mini-lathe, light cuts, sharp HSS tooling with generous rake, and plenty of cutting fluid prevented smearing. If you’re used to free-machining brass, expect copper to be a bit gummier.

Forming and bending

The stock I received behaves like soft-drawn/annealed copper. I can form a gentle 10–12 mm radius bend by hand without cracking, and it springs back very little. For coils and repeatable curves, a simple wooden dowel jig or a small tubing/rod bender produces neat results. As with all copper, multiple re-bends work-hardens the material; if you’re doing complex shapes, plan the sequence or re-anneal with a torch between operations.

Joining: soldering, brazing, and welding

Solderability is excellent once the surface is clean. For electronics, rosin flux and a 60–80 W iron give reliable wetting, but remember that copper conducts heat away fast—use a larger tip, preheat the joint, and consider heat-sink clips to protect nearby components. For mechanical joints, a zinc chloride paste flux and lead-free silver-bearing solder make robust connections. I also silver-brazed a test joint with a small propane torch; it flowed beautifully, though the heat does discolor the surface (easily cleaned later). TIG welding copper at this diameter is possible but unforgiving because of the heat sink effect; most users will be better served by soldering or silver brazing.

Electrical and thermal performance

This is where these rods earn their space. Each 3 mm rod has a cross-sectional area of roughly 7 mm², comparable to a heavy-gauge conductor. I used a pair as a low-voltage DC bus in a bench supply mock-up; voltage drop stayed negligible over short runs, and the rods never got more than warm at tens of amps. For RF work, they make tidy loop and coil elements with predictable behavior. Thermally, the rods are handy as heat spreader pins and custom standoffs—great for moving heat out of a small module to a chassis wall.

Consistency across the six-pack

Lengths were within a millimeter of 305 mm, ends square, and diameters consistent rod-to-rod within a few hundredths of a millimeter (again, right around 3.00 mm). That consistency matters when you’re building mirrored parts or winding matched coils. I didn’t find any hard spots, voids, or seams.

Durability and corrosion

Bare copper will tarnish. A light patina set in within days of handling, which has no practical downside for most uses but does dull the finish. Before soldering, I always scuff with a fine abrasive and wipe with alcohol. If you care about appearance or long-term oxidation, a clear lacquer, shellac, or conformal coating keeps the shine. Outdoors, expect verdigris over time unless you protect it.

Where these rods fit in the shop

- Electronics: ground buses, jumpers, probe tips, connectors, coil forms.

- Model making: pins, axles for light-duty mechanisms, decorative elements.

- Thermal jobs: custom heat spreaders, thermal bridges to a chassis.

- Fixtures: alignment pins, spacers, and quick jigs where conductivity or softness helps.

For anything requiring high structural strength, copper isn’t your friend. It dents and bends more easily than steel or even some brasses.

Limitations and gotchas

- Diameter reality: treat the rods as 3 mm, not a true 1/8 inch. If you need 0.125-inch stock, look elsewhere.

- Softness: wonderful for forming and electrical work, not suitable for load-bearing shafts or wear surfaces.

- Machining feel: gummy compared with brass; sharp tooling and light cuts are essential.

- Heat sink effect: plan for more heat when soldering or brazing; smaller irons struggle.

None of these are faults; they’re inherent to C110 copper and the chosen diameter.

Value

Buying six 12-inch sticks gives you a practical amount of stock to experiment with and build multiple small projects. Compared with grabbing single pieces from a hobby rack, the per-rod cost works out well, and the consistency of temper and diameter across the pack is better than the mixed-lot odds I sometimes get locally. There isn’t much to “feature” with copper rod beyond good material and finish, and that’s exactly what’s delivered here.

Recommendation

I recommend these copper rods. They’re straight, clean, genuinely C110, and sized consistently at 3 mm—ideal for electrical and thermal jobs, quick fixtures, and hobby fabrication. As long as you understand the material’s softness and the metric diameter, they’re easy to work with and versatile. I keep a pack on hand because they save me time: I can cut, bend, and solder a solution in minutes without hunting for the right fit or finish. For anyone doing electronics, model work, or light metal DIY, this is a dependable, no-drama stock to keep in the drawer.

Project Ideas

Business

Handmade Minimalist Jewelry Line

Produce a small collection of copper bar earrings, cufflinks, and pendant bars. Market the natural warm tone or offer patinated/antiqued finishes. Use the 6‑pack rods to produce multiple pairs per set; emphasize handmade, sustainable metal and small‑batch exclusivity on Etsy or local boutiques.

Electronics & Maker Supply Packs

Sell pre‑cut 1/8" copper rod lengths as kits for hobby electronics: custom bus bars, grounding pins, probe leads, or heatsink pins for DIY projects. Promote the high conductivity (99.9% C110) and burr‑free finish to makers, makerspaces, and electronics hobbyists.

Craft Kits & Local Workshops

Package beginner kits (e.g., 'Make Your Own Wind Chime' or 'Copper Earrings Kit') including rods, findings, instructions and small tools. Run paid hands‑on workshops teaching cutting, annealing/bending, soldering and finishing—charge workshop fee + sell kits onsite.

Custom Model Parts & Fabrication Service

Offer a small fabrication service making precision components for scale modelers, architects, and hobbyists: railings, struts, masts, and bespoke connectors. Use the rods' consistent diameter and smooth finish as a selling point; price per part or by project.

Home Décor Micro‑Products

Create a line of small home goods: copper cocktail stirrers, drawer pulls/pegs, plant stakes, minimalist curtain tiebacks or tiny sculptures. Market as handcrafted accents; protect with clear lacquer and sell in small lots online or at craft fairs.

Creative

Minimalist Bar Earrings

Cut the 12" copper rods into matched short lengths (20–40 mm), file ends smooth, drill or wrap for ear wires and finish by polishing or applying a dark patina. The 1/8" diameter is stiff enough to hold shape but thin enough to trim and bend for lightweight, modern earrings or bar necklaces.

Mini Trellis & Plant Markers

Use the rods to make small trellises for succulents or herb markers. Bend and solder small frames (or cold‑connect with wire), stamp or engrave plant names on short rod sections, and lacquer for outdoor protection. The smooth 3mm rods are ideal for clean, architectural plant accents.

Tuned Wind Chimes / Kinetic Mobile

Cut rods to different lengths to create musical chimes (length correlates to pitch). Hang with fishing line between a wooden ring or driftwood for a kinetic mobile. The copper's density and smooth finish give a warm tone and attractive visual reflection.

Scale Model Structural Details

Use straight lengths for railings, masts, antennae, or axles in ship and architectural models. The consistent 1/8" diameter is great for structural detail; rods can be soldered or glued into resin/wood models and finished with patina or lacquer.

Geometric Soldered Ornaments

Create small geometric shapes (diamonds, cubes, triangles) by cutting and soldering rod ends. Leave polished, hammer for texture, or apply liver of sulfur for a dark finish. Use as ornaments, gift tags, or modern tree decorations.