Specifications

| Release Date | 2019-05-21T00:00:00.000Z |

| Pages Count | 238 |

| Publication Date | 2019-05-21T00:00:00.000Z |

Related Tools

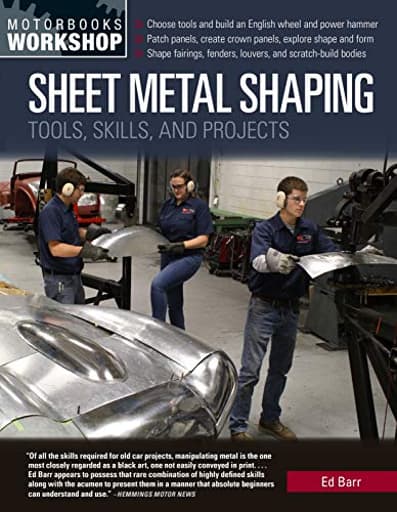

A 238-page workshop guide that explains the tools, techniques, and projects used to shape sheet metal. It provides step-by-step instructions and illustrations for metalforming tasks such as cutting, bending, shrinking, stretching, planishing, and basic welding, with project walkthroughs to build practical skills.

Motorbooks Sheet Metal Shaping: Tools, Skills, and Projects Review

Why this guide earned a spot on my bench

I keep a rotating stack of references next to my English wheel and welder, and this book quickly moved to the top. It’s a practical, 238‑page workshop companion focused on shaping sheet metal with the tools most of us actually own. The tone is friendly without being fluffy, and the instruction is grounded in repeatable methods. If you’ve ever stared at a rusty arch and wondered how to recreate it from flat steel, this guide shows a path from layout to finish that you can follow at your own pace.

What’s inside and how it’s organized

The book covers the core sequence of metalforming: planning, cutting, bending, shrinking, stretching, planishing, and basic welding. Each topic is broken into small, logical steps with photos and drawings that make it easy to pause, try a step on the bench, and return.

Highlights that stood out in daily use:

- Clear breakdown of where each tool shines: mallets and bags for broad shapes, slappers and dollies for smoothing, shrinker/stretchers for flanges and returns, and simple forms for consistency.

- Smart emphasis on patterning. There’s solid coverage of card templates, tape-and-foil flexible shape patterns, and profile gauges to keep you honest about the shape you’re chasing.

- Welding guidance that prioritizes metal finishing. Whether you’re using O/A, TIG, or MIG with stitch techniques, the book shows how to planish and file a seam so it disappears instead of sinking.

Projects are integrated throughout to reinforce skills: simple bowls and scoops for compound curves, patch panels with wired edges, rolled flanges around tight radii, and repairs that mimic real automotive work. Each project builds on the last, so you’re not just reading—you’re practicing.

Using it in the shop: what I made

I tested the book with a few practical jobs:

1. A small compound‑curve patch for a pickup cab corner (18‑g steel). I followed the book’s grid marking and tuck shrinking sequence on a sandbag, refined on a stump, and finished with a slapper/dolly. The guidance on working “highs to lows” while maintaining crown helped me avoid that dreaded potato‑chip effect.

2. A wired edge for a headlight bucket. The method for consistent hem depth and smoothing the wire‑edge bulges with a spoon and post dolly produced a clean, uniform lip without specialized dies.

3. A quick shrinker/stretcher flange around a tight arch with controlled relief cuts. The book’s advice to sneak up on the curve and stress‑relieve before planishing reduced oil canning, and the flange sat flat against the buck on the first try.

None of these required a power hammer or a high‑end wheel; just a sandbag, a couple of mallets, a slapper, and an assortment of dollies. That aligns with the core premise: you can do real work with modest tools if you understand the sequence and the why behind each strike.

Techniques that translate

A few techniques from the book became immediate habits:

- Layout and tracking: Draw a loose grid on the blank and check how squares distort as you work. It’s a fast, visual way to see where you’re stretching (thin spots) or over‑shrinking (buckling).

- Flexible shape patterns: Build a tape shell on the part you want to copy, slit it free, and transfer it onto your blank. It preserves compound curvature better than flat card and keeps you honest about the crown.

- Controlled shrinking order: For tuck shrinking, start at the apex and work symmetrically outward, keeping tucks small and consistent. This kept my panel smooth and the final planishing light.

- Heat and cleanliness: Polish hammer faces and keep work surfaces clean. The book repeats this often, and it’s right—surface finish on tools shows up immediately in the panel.

The welding chapters are pragmatic. If you only have MIG, you’ll still learn to stitch, skip, and planish with a dolly to minimize hard seams. If you use TIG or gas, there’s solid advice on fusing with minimal filler to maintain thickness for later smoothing. The section on metal finishing with files and raking light is worth the price of admission; it’s systematic and reduces guesswork.

On aluminum, steel, and expectations

This isn’t a metallurgy textbook, but it covers what you need to avoid common traps. The book explains how aluminum moves differently than steel, shows a simple anneal test, and demonstrates how to adapt your strike and support for softer alloys. For steel, it emphasizes crown and support more than brute force. I appreciated the reminders to sneak up on shape and to stop early, check, and return rather than “fix” stretched zones later.

If you’re already deep into advanced wheeling or die work, you’ll find the fundamentals reinforced but not reinvented. The coverage of powered equipment is present but the bias is toward hand methods and simple fixtures. That’s not a flaw—just a clear editorial choice to center technique over machinery.

Photos, drawings, and Kindle reading experience

On a 10‑inch tablet, the photos and line drawings are crisp enough to zoom and study. Captions carry a lot of instructional weight, so don’t skip them. On a phone, diagrams can feel cramped; I ended up bookmarking spreads and reviewing them on a larger screen before heading to the shop.

Navigation is good: chapters are logically named, and internal links let you jump to tool primers from project steps. Search works well for quick hits like “wired edge” or “tuck shrink.” My only gripe is that some step‑to‑step photo sequences would benefit from an extra frame between rough‑out and finish to make the transitions clearer.

Where it falls short

- If you’re looking for deep dives into specific machines (e.g., advanced English wheel tracking, louvre dies, or power hammer tooling), you’ll get an overview but not a master class.

- Complete beginners may want a brief glossary up front; the book defines terms in context, but a consolidated list would help first‑time readers.

- A few Kindle photo spreads are busy on small screens. It’s workable with zoom, but a tablet or desktop makes a difference.

None of these are deal‑breakers, and they don’t undermine the core value: repeatable techniques, explained simply, that you can practice at home.

Who it’s for

- Hobbyists working out of a garage who want to fabricate legitimate patch panels and small assemblies without buying a shop’s worth of gear.

- Restoration techs and fabricators who want a structured refresher on fundamentals and a set of practice projects to sharpen hand skills.

- Students in automotive or metal arts programs who need clear process photos and sensible sequences they can replicate between classes.

If your work is mostly aerospace‑grade aluminum or you live exclusively on powered equipment, you’ll still find useful patterns and finishing advice—but it’s not the focus.

Tips to get the most from it

- Read a section, then do the exercise immediately with scrap. The projects are designed to build muscle memory, not just understanding.

- Keep a small “witness panel” next to your work. Apply the technique there first, evaluate, then return to the real piece. You’ll waste less material.

- Photograph your panel under raking light at each stage. Comparing to the book’s intermediate photos helped me see where I was drifting.

Bottom line

This book earns its keep by treating metal shaping as a sequence of small, controllable actions instead of mystique. It shows how to get there with a limited toolset, it emphasizes patterns and verification so you’re not guessing, and it invests heavily in finish quality so your welds and shapes look intentional. The writing is approachable, the photos do real instructional work, and the projects are practical enough to become parts you keep on the vehicle.

Recommendation: I recommend this guide for anyone who wants to build real sheet‑metal skills without relying on expensive machinery. It’s especially strong for garage fabricators and restoration work because it focuses on method, not gear, and provides projects that reinforce the fundamentals you’ll actually use. Even if you’re experienced, the sections on patterning, planishing strategy, and metal finishing are solid enough to sharpen your process.

Project Ideas

Business

Hands-on Beginner Workshops

Run tiered in-person classes (intro fundamentals, intermediate shaping, specialty projects) teaching the techniques in the guide. Charge per session, offer multi-class bundles and sell starter tool kits and safety gear. Market to makerspaces, community centers, and via social media; partner with local suppliers for materials discounts.

Custom Home Décor & Commission Shop

Offer bespoke metal decor: wall panels, lamp fixtures, planters and mailboxes tailored to clients. Use the guide’s projects as templates and expand to commissions—sell through an ecommerce site, Etsy, local galleries and interior designer partnerships. Add value with design consultation, installation and premium finishes.

Restoration & One-off Patch Panel Service

Specialize in making precision replacement panels for classic cars, motorcycles and vintage appliances. Provide digital templates, custom-fit panels and weld-ready parts; sell direct to restorers and shops. Upsell by offering on-site patterning, rust repair consulting and finishing services.

Digital Plans, Patterns & Video Course

Productize the guide into downloadable templates (DXF/CAD), step-by-step PDFs and an online video course demonstrating techniques and projects. Offer tiered access (single project purchases, full course subscription) and add a private community for members. Low overhead and scaleable—promote via social media, YouTube snippets and maker forums.

Prototype & Low-volume Production Service

Use sheet-metal forming skills to prototype and produce small runs for designers, furniture makers and inventors. Offer DFM consulting, patterning, forming and finishing (powder coat, plating). Market to local designers, product studios and crowdfunding campaigns—price projects by complexity and batch size.

Creative

Geometric Folded Wall Panels

Design a series of interlocking folded sheet-metal panels (triangles, hexagons, waves) that mount as decorative wall art. Teaches cutting, bending, shrinking/stretching and planishing; finish with powder coat or patina for high-end look. Modular panels let you create custom-sized installations for homes or commercial spaces.

Custom Lampshades & Light Fixtures

Form domed or faceted metal shades with pierced-pattern cutouts to create dramatic light effects. Project covers forming (stretching/shrinking), hole-punching patterns, wiring accommodations and finishes. Great for combining functional skills with sculptural design—good portfolio pieces or retail items.

Outdoor Planter Sculptures

Make weatherproof, shaped planters and freestanding sculptural containers using thicker sheet metal, seams, and basic welding. Practice bending, shrinking, and seam finishing, then add drainage and protective coatings. These durable, sculptural planters work well for boutiques, galleries, and gardens.

Automotive Patch & Restoration Panels

Create small replacement panels (patches, inner fender pieces, trunk floor sections) to learn precise shaping and fitment. Emphasis on templates, shrink/stretch techniques and clean weld-in practice—excellent hands-on skill builders for hobbyist restorers. Finished examples make great portfolio shots for mechanically minded makers.

Wearable Metal Accessories

Produce cuffs, belts, collars, and statement jewelry from thin sheet metal using forming and planishing techniques. Explore doming, texturing, hinges and rivets plus finishing (brush, patina). Small-scale, low-cost projects that are great for markets and to experiment with finishes and materials.