Features

- For use on commercial or personal boats

- Also used on equipment and oil rigs

- Resists rust and corrosion

- Use on most structural objects

- Professional quality marine paint

Specifications

| Color | Blue |

| Size | 32 Fl Oz (Pack of 1) |

| Unit Count | 1 |

Related Tools

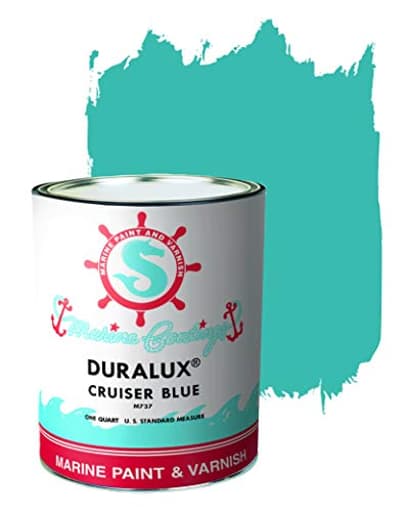

Topside marine enamel in cruiser blue, sold as a 1-quart (32 fl oz) can, intended for maintenance of boats and other onshore or offshore structures. It adheres to steel, metal, wood, fiberglass and aluminum and is formulated to resist rust and corrosion on equipment, oil rigs and other structural objects.

DURALUX Marine Enamel, Cruiser Blue, 1 Quart, Topside Paint for Boats and Other Onshore or Offshore Marine Maintenance Applications, Adheres to Steel, Metal, Wood, Fiberglass & Aluminum Review

Why I reached for this paint

I had three small-but-visible projects staring at me: the sun-faded topsides of a fiberglass dinghy, the scuffed interior of a 14-foot aluminum skiff, and a steel dock locker that rusted every time the breeze turned salty. I wanted one can that could handle all three without looking like a compromise. I picked up a quart of Duralux’s Cruiser Blue marine enamel and set aside two weekends to see what it could really do.

Surface prep and setup

This is a traditional solvent-borne topside enamel, so you win or lose on preparation. Here’s what worked for me:

- Fiberglass dinghy topsides: wet-sanded to 220 grit to knock the shine off, washed with mild soap, rinsed thoroughly, allowed to dry, then wiped with a fast-evaporating solvent and a clean tack cloth.

- Aluminum skiff interior: de-greased thoroughly, scuff-sanded to a uniform dull finish, and spot-primed the bare aluminum with a compatible metal primer. Aluminum is unforgiving—primer on any burn-throughs made a noticeable difference in adhesion.

- Steel locker: hand-sanded rust to bright metal, feathered surrounding paint, treated any staining, and primed the bare spots. I made sure edges and seams were clean and dry before painting.

I strained the paint before use and mixed gently to avoid introducing bubbles. For rolling and brushing, I didn’t thin. For a light spray pass on the locker’s louvered panels, I reduced it slightly per the reducer’s guidance and got a smoother film without orange peel.

Ventilation matters. This paint has a classic solvent smell; I worked outdoors or with doors wide open and a respirator on the spray day. Cleanup was straightforward with mineral spirits.

Application: brush, roll, and a little spray

On large, flat areas I used a 1/4-inch foam roller and immediately “tipped off” with a good natural-bristle brush. The paint levels well, so two light passes beat one heavy pass. On vertical panels, if you load the brush too much you’ll get sags; tip-off and a watchful eye for the first 15 minutes keeps them in check.

Spraying the louvered steel vent gave the most uniform film, but rolling the hull and interior panels was almost as smooth thanks to the paint’s self-leveling. If you’re new to this, work in smaller sections than you think you need to—this enamel stays open long enough to blend edges, but you don’t want to chase it.

Coverage and color

Coverage impressed me. Out of a single quart I covered:

- The dinghy’s topsides (two coats over scuffed gelcoat).

- The skiff interior and gunwales (two coats over spot-primed aluminum).

- The dock locker’s door and frame (one coat over primer), with a bit left for touch-ups.

My real-world tally worked out to roughly 90–110 square feet of honest coverage per quart per coat, depending on how thirsty the surface was.

Cruiser Blue is a confident, saturated marine blue—bright enough to look crisp in the sun, not so dark that it reads black on cloudy days. Across different substrates, the color matched closely from coat to coat. If you’re blending old and new, expect a slight shift from sun-aged surfaces; otherwise, it’s uniform and clean.

Finish and slip

The gloss is high and even. On the dinghy it looks almost wet when cured—a classic topside finish. On the skiff’s interior, that gloss is attractive but slick when damp. If you plan to walk on it, sprinkle in a non-skid additive for the final coat or mask and roll non-skid strips after the fact. I added a fine silica additive to the forward deck and it solved the traction problem without muting the color too much.

Drying and curing

Patience helps with solvent enamels. In mild weather, it skinned over in a few hours and was dry to a cautious touch later that day, but “hard” took longer. I waited overnight between coats and a full week before dragging fenders or coolers across it. If you rush recoat, you risk print-through or soft spots. My take: schedule this paint so you can let it cure in peace.

One practical note: dust control. Because the film stays open long enough to level nicely, it also stays open long enough to catch a stray hair or speck. A quick tack between coats and working in the least-breezy portion of the day kept nibs to a minimum.

Adhesion and durability

After a full cure and a season of use—sun, salt air, and more than a few scuffs—the finish has held up well:

- Fiberglass topsides: no chalking so far, gloss still strong, and fender rubs haven’t cut through. Light scuffs buff out; deeper ones touch up easily because the paint blends into itself without hard edges.

- Aluminum interior: the high-wear edges (gunwales and seat fronts) show honest use—some shiny burnish and a couple of chips where anchors bumped—but the paint hasn’t lifted or peeled from the scuffed and primed aluminum.

- Steel locker: water beads and no rust bleed-through at seams yet, a good sign that the film is sealing well. That said, prime any exposed steel; relying on topcoat alone is a false economy.

It’s worth underscoring what this enamel is and isn’t. It’s a topside paint designed for splash, spray, and weather—great above the waterline, on decks (with non-skid), consoles, rails, lockers, and doors. It is not a pond-liner or below-the-waterline coating. Constant submersion or flexible liners are the wrong use-case and will disappoint.

Maintenance and touch-ups

Cleaning has been simple: mild soap, soft brush, rinse. Avoid aggressive solvents or scouring pads. For touch-ups, I scuffed the spot lightly, wiped clean, and dabbed on a small amount with a fine brush. Because the enamel levels, the repair floats into the surrounding area better than I expected; after a week, most touch-ups are hard to spot unless you know where to look.

What I liked

- Strong coverage and color depth; two coats provided a deep, uniform finish.

- Excellent leveling for a brush-and-roll job; near-spray results on large panels.

- Versatility across fiberglass, aluminum (with primer), and steel (with primer).

- Good weather resistance and gloss retention over a season.

- Touch-ups blend nicely without telegraphing edges.

What could be better

- Long cure to full hardness; plan for downtime and avoid rushing.

- High gloss is slippery when wet unless you add non-skid.

- Prone to sags if over-applied on vertical surfaces; light coats are key.

- Solvent odor and VOCs require ventilation and basic PPE.

- Not suitable for continuous immersion or flexible substrates.

Tips for best results

- Take prep seriously: scuff every square inch and prime bare metal.

- Strain the paint and stir gently; avoid shaking to reduce bubbles.

- Roll thin, tip off immediately, and watch for drips for the first 15 minutes.

- Give it time: overnight between coats, a week to fully harden in average conditions.

- Add a non-skid additive anywhere feet will go.

- If spraying, reduce modestly with the recommended thinner and keep to light passes.

Value and who it’s for

Per quart, the mileage I got—and the finish quality I ended up with—feel like strong value. For owners refreshing small boats, dockside fixtures, or marine-adjacent hardware, one can goes further than you’d think. If you need a below-waterline solution or a coating for constant immersion, this isn’t the product; look to bottom paints or specialized liners. But for topside and structural applications, the combination of adhesion, gloss, and durability is hard to fault at this price.

Recommendation

I recommend Duralux’s Cruiser Blue marine enamel for topside and structural projects on fiberglass, aluminum, wood, and steel where you want a durable, high-gloss finish and are willing to do proper prep and allow adequate cure time. It rewards careful application with professional-looking results, holds up respectably in sun and spray, and touches up cleanly. Add non-skid on walking surfaces and keep it out of continuously submerged roles, and you’ll be pleased with both the process and the outcome.

Project Ideas

Business

Mobile Boat Touch-Up Service

Offer on-site one-quart touch-up jobs for hull chips, topside scratches and small corrosion spots; bundle material cost (one-quart cans) with labor, provide color-matching and a follow-up seasonal inspection to generate recurring revenue.

Coastal Furniture & Decor Line

Design and sell outdoor furniture, planters and decor finished with marine enamel for long-lasting coastal performance; market to vacation rental owners, boutiques and waterfront homeowners as 'marine-grade' lifestyle pieces.

Refurb & Preventative Maintenance Contracts

Contract with marinas, boatyards and small industrial operators to refurbish metal fixtures, railings and small equipment using rust-resistant marine enamel; provide scheduled maintenance packages to protect assets and lock in steady income.

DIY Repair Kits and Workshops

Assemble 1-quart repair kits (paint, brush, sandpaper, instructions) and run weekend workshops teaching simple marine touch-up and corrosion-prevention techniques; sell kits online and at local marine stores to capture DIY customers.

Branded Promotional & Corporate Gifting

Create small branded items (coaster sets, key racks, model boats) finished in cruiser blue as premium promotional gifts for marinas, boat brokers and coastal businesses; offer private-labeling and volume discounts to corporate clients.

Creative

Retro Nautical Wall Signs

Use reclaimed wood planks primed and painted with cruiser blue as a base; stencil or hand-letter nautical sayings, distress edges for an aged look, and seal with a clear topcoat for indoor/outdoor display. Great for coastal homes, porches or beach rental décor.

Upcycled Metal Patio Chairs

Strip rust from old metal chairs, apply rust-inhibiting primer, then finish with the marine enamel in cruiser blue for a durable, weatherproof outdoor seating set — add seat cushions in complementary colors for contrast.

Scale Boat Hull Models & Display Pieces

Build or buy fiberglass/wood boat models and use the marine enamel for a high-gloss, realistic topside finish that resists handling wear; ideal for gifts, retail display, or selling as coastal décor.

Industrial Pipe Shelving with Blue Accents

Create wall-mounted shelving using steel pipe and wood planks; paint the metal pipe supports with cruiser blue to make a feature color that resists rust for humid or semi-outdoor spaces like garages and patios.

Tool Chest & Gear Restoration

Repaint metal tool chests, lockers, or gear trunks with the marine enamel to stop corrosion and give a professional, uniform cruiser-blue finish — add custom labeling or vinyl decals for personalization.