- Building Supplies

- Electrical

- Smart Home, Security, Wi-Fi

- TV & Home Theater

- Extension Cords & Surge Protectors

- Electrical Wire & Cable

- Service Entrance Cables

- Primary Wire

- Sprinkler Wire

- Security Cables

- Armored Cable

- Power Cord

- Thermostat Wire

- Network & Data Cables

- XHHW Wire

- Specialty Wire & Cables

- Ground Wire

- Cable & Wire Holders

- Electrical Whips & Whip Kits

- Dual Armored Cable

- Non-Metallic Wire

- Landscape Lighting Cables & Connectors

- UF Wire

- TFFN & THHN Wire

- Speaker Wire

- Submersible Pump Cables

- Cable & Wire Connectors

- Wall Plates & Inserts

- Conduit & Conduit Fittings

- Generators

- Electronics

- Light Sockets & Adapters

- Electrical Outlets & Plugs

- Electrical Testers & Tools

- Batteries

- Fire Safety

- Light Switches & Dimmers

- Electrical Boxes & Covers

- Solar Power

- Doorbells

- Power Distribution & Circuit Protection

- Electrical Tape

- Lawn & Garden

- Garden Hoses & Accessories

- Landscaping & Hardscaping

- Outdoor Tools & Equipment

- Snow Blowers, Parts & Accessories

- Lawn & Garden Hand Tools

- Chainsaws & Pole Saws

- Spreaders & Sprayers

- Power Equipment Combo Kits

- Trimmers & Edgers

- Power Equipment Parts

- Lawn Aerators

- Engine Oil

- Wheelbarrows & Yard Carts

- Pressure Washers

- Snow Plows & Accessories

- Leaf Blowers

- Log Splitters

- Tillers & Cultivators

- Mulchers & Wood Chippers

- Axes & Mauls

- Power Equipment Fuel

- Garden Decor

- Outdoor Fountains

- Ponds

- Weathervanes

- Bird & Wildlife

- Garden Bridges

- Garden Arbors & Trellises

- Garden Fencing

- Well Pump Covers

- Garden Stakes & Shepherds Hooks

- Flags & Banners

- Outdoor Decorative Lanterns

- Garden Statues & Sculptures

- Outdoor Torches & Candles

- Thermometers, Clocks & Gauges

- Garden Stools

- Wind Chimes & Twisters

- Insect & Pest Control

- Pots & Planters

- Grills & Outdoor Cooking

- Irrigation & Outdoor Drainage

- Lawn Mowers

- Plant Care

- Storage & Organization

- Plumbing

- Water Heater Parts & Accessories

- Pipe & Fittings

- CPVC Pipe & Fittings

- Push to Connect Fittings

- Polyethylene Pipe, Fittings & Accessories

- Pipe Support & Clamps

- PEX Pipe, Fittings & Specialty Tools

- Tubing & Hoses

- Sewage Pipe & Fittings

- Structural Pipe & Fittings

- ABS DWV Pipe & Fittings

- Copper Pipe & Fittings

- CSST Pipe & Fittings

- Galvanized Pipe & Fittings

- Brass Fittings

- Pipe Insulation

- Black Pipe & Fittings

- PVC DWV Pipe & Fittings

- PVC Pipe & Fittings

- Water Filtration & Water Softeners

- Supply Lines

- Utility Sinks & Faucets

- Water Pumps & Tanks

- Valves & Valve Repair

- Water Heaters

- Plumbing Parts & Repair

- Augers, Plungers & Drain Openers

- Plumbing Tools & Cements

- Tools

- Air Tools & Compressors

- Hand Tools

- Clamps & Vises

- Hand Saws & Blades

- Taps & Dies

- Cutting & Crimping Tools

- Staple Guns & Riveters

- Multi-Tools

- Pliers & Plier Sets

- Punches & Knockout Punch Sets

- Sockets & Socket Adapters

- Maintenance Tools

- Powder Actuated Tools & Fasteners

- Ratchets & Breaker Bars

- Chisels & Pry Bars

- Mechanics Tool Sets

- Household Tool Sets

- Nut Drivers & Keys

- Files & Planes

- Grease Guns & Fittings

- Wrenches & Wrench Sets

- Hammers

- Screwdrivers

- Levels & Measuring Tools

- Drills & Drivers

- Clothing

- Ladders & Scaffolding

- Power Tools

- Safety

- Tool Storage & Work Benches

- Shop Vacuums & Accessories

- Flashlights

- Welding & Soldering

- Jobsite Radios

- Paint

- Heating & Cooling

- Furnaces & Furnace Accessories

- HVAC Duct & Fittings

- Registers & Grilles

- Thermostats

- Fireplaces & Stoves

- Humidifiers & Dehumidifiers

- Air Conditioners & Fans

- Through Wall Fans

- Whole House Fan Shutters

- Ductless Mini Splits

- Blower Fans

- Portable Air Conditioners

- Evaporative Coolers

- Evaporative Cooler Accessories

- Whole House Fans

- Window Air Conditioners

- Wall Air Conditioners

- Wall Mounted Fans

- Central Air Conditioners

- Air Conditioner Parts & Accessories

- Portable Fans

- Whole House Fan Timers

- Air Filters & Accessories

- Air Purifiers & Accessories

- Portable & Space Heaters

- HVAC Components

- Heat Pumps

- Underfloor Heating

- Heating Fuel Tanks

- Radiator Covers

- Boilers

- Cleaning Supplies

- Hardware

- Cabinet Hardware

- Door Hardware

- Door Latch Hardware

- Door Security

- Closet Door Hardware

- Door Jamb Security & Repair Kits

- Pocket Door Hardware

- Screen & Storm Door Hardware

- Door Knockers

- Deadbolts

- Barn Door Hardware

- Door Sweeps

- Bathtub & Shower Door Hardware

- Sliding Patio Door Hardware

- Screen & Storm Door Handles

- Door Closers

- Door Handles

- Door Knobs

- Door Hinges

- Electronic Door Locks

- Door Kick Plates

- Door Stops

- Handlesets

- Picture Hangers

- Window Hardware

- Metal Rods, Shapes & Sheets

- Specialty Hardware

- Safes

- Furniture Hardware

- Fasteners

- Chains, Ropes & Tie-Downs

- Signs, Letters & Numbers

- Keys & Key Safes

- Locks

- Hooks

- Marine Hardware

- Automotive

- Lighting

- Flooring

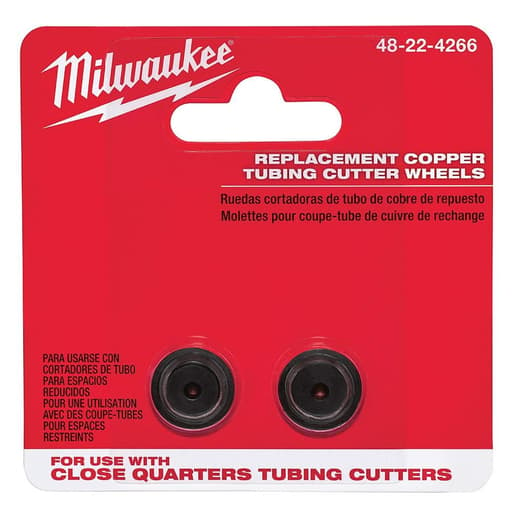

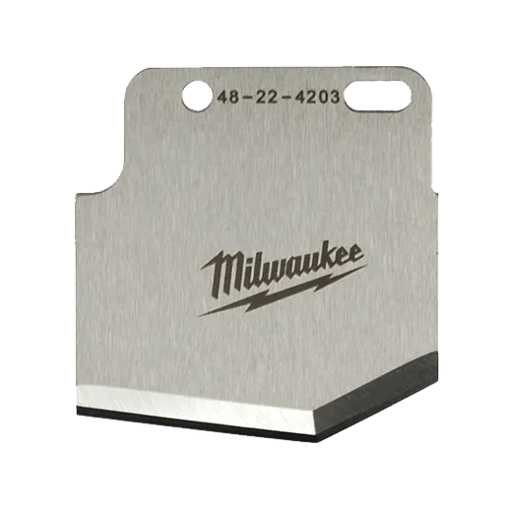

Plumbing tools and cements help you build leak‑free, code‑compliant systems and keep fixtures running smoothly. Whether you are installing new lines, upgrading valves, or tackling a quick repair, the right gear saves time and prevents costly callbacks. Core hand tools include pipe wrenches, adjustable wrenches, basin wrenches for hard‑to‑reach nuts, and tubing cutters for copper, PVC, and PEX. Add deburring tools and reamers for clean edges, plus PEX crimp or expansion tools for secure connections. For soldered joints, stock a torch, flux, solder, heat shield, and a fire‑safe work area. For clogged drains, plungers, drum augers, and inspection cameras speed diagnosis and clearing.

Choosing the right bonding product is critical. Use PVC, CPVC, or ABS solvent cement matched to pipe type, schedule, and temperature rating, and apply primer where required by code. Solvent welds chemically fuse the joint for high strength; follow set and cure times and avoid stress until fully cured. For threaded fittings, pick PTFE tape or pipe thread sealant paste to stop seepage and ease future disassembly. For emergency fixes and odd materials, keep epoxy putty, silicone sealant, and repair clamps on hand. Always clean, dry‑fit, mark alignment, then apply primer and cement evenly. Rotate a quarter turn, hold pressure, wipe excess, and allow proper curing before pressurizing.

Smart selection boosts productivity. Match cutters to material thickness, use a chamfer tool on plastic pipe, and choose crimp rings or expansion sleeves approved for your PEX brand. A pressure test gauge verifies systems before drywall. Threaders and dies create custom nipples on site. Keep a pipe support system, hangers, and insulation to reduce noise. Prioritize safety: ventilate around solvents, cap gas lines, wear gloves and eye protection, and keep sparks away from primers and cements. Quality plumbing tools and cements deliver cleaner installs, fewer leaks, and faster service.