Features

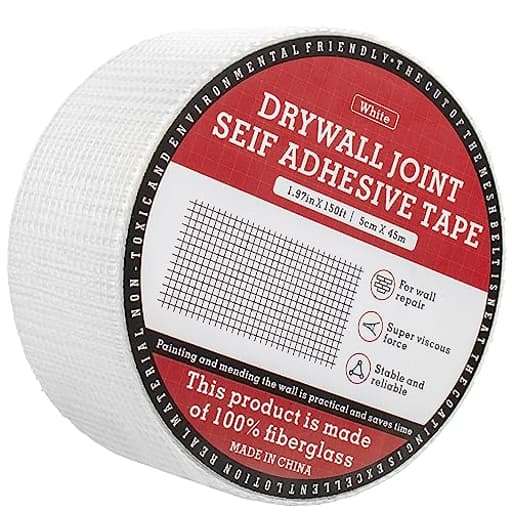

- ✔【Fiberglass Mesh Tape】Fiberglass mesh is made of high quality and high density glass fiber. Corrosion resistant, high temperature resistant, toughness

- ✔【Multipurpose Function】Drywall tape is used to quickly repair cracks, fill holes and patching commonly found in plaster and small hole drywall installation, also can be used in cement joints and tile installation

- ✔【Strong Adhesion】 Sheetrock tape with strong adhesion, easy to use, no need to pre-apply seam sealer, can be repositioned, suitable for those difficult jobs

- ✔【Applicable Scope】Drywall Mesh Patch widely used for joining plasterboard, repairing cracks and sealing small holes in the seams, strengthening and finishing the joints of indoor drywall panels.

- ✔【Suitable Size】 Drywall mesh single roll. Size: 1.97inch x 150feet. 100% fiberglass material, suitable for most application scenarios. Can accommodate more difficult jobs than tape patches.

Specifications

| Color | 1 pcs (1.97in×150feet) |

| Size | 1.97"×150Ft |

| Unit Count | 1 |

Self-adhesive fiberglass mesh tape (1.97 in × 150 ft) for joining plasterboard and repairing cracks, seams, and small holes in drywall. The tape is made of high-density fiberglass that is corrosion- and heat-resistant, offers strong adhesion without pre-applied seam sealer, can be repositioned during installation, and is also suitable for cement joints and tile work.

NEZUIBAN Drywall Joint Tape, Fiberglass Mesh Tape for Drywall Repair,1.97“×150 Ft Self-Adhesive Drywall Mesh Tape for Sheetrock Crack Repair Review

What this tape is good for

I put the NEZUIBAN mesh tape through a handful of real-world drywall fixes: bridging hairline cracks over doorways, reinforcing a butt joint on a new sheet, and patching a half-dollar–sized hole left by an old wall anchor. It’s a 2-inch-wide, 150-foot roll of self-adhesive fiberglass mesh, which puts it squarely in the “get it done quickly” category. It’s meant to be stuck directly over seams or cracks and then buried in compound—no bedding coat required to hold the tape in place.

As a rule, mesh tape shines for repairs and flat seams and is less ideal for inside corners (paper tape still wins there). This roll follows that pattern, but with a couple of pleasant surprises in handling and cleanup.

Build and handling

The mesh feels dense and consistent. It’s stiff enough to bridge small voids without collapsing into them, yet flexible enough to follow mild wall irregularities. The edges cut cleanly with a knife or tear evenly by hand without fraying into fuzz. That may sound minor, but a fringe of loose fiberglass can telegraph through finish coats and catch on your knife; I didn’t run into that here.

Adhesion is balanced. The tape isn’t gummy, which I appreciate—overly aggressive adhesive can stretch the mesh or leave residue on knives. On clean painted drywall, it stuck reliably and allowed a couple of lifts and repositions without the fibers distorting. On dusty or flat-primed surfaces, I had to wipe down first; otherwise, edges lifted when I pulled a knife across them. Once pressed down with a 4–6 inch knife, it stayed put for compound.

The roll feeds smoothly and doesn’t telescope or collapse on the core. That makes it easy to pull long lengths for seams without fighting the roll.

Application and performance on drywall

Cracks: I raked out a vertical crack to remove loose material, wiped clean, and ran the tape centered over it with 1–2 inches past each end. First coat was a setting-type compound (45-minute), pressed firmly through the mesh to anchor it and fill the grid. Two finish coats of all-purpose compound feathered to 8–10 inches left a flat surface with no pinholes. After a few weeks, no ghosting or shadow of the mesh has appeared, and the crack hasn’t returned.

Small holes: For a roughly half-dollar–sized hole, I ran a cross of tape and then a square over it, creating a mini “patch panel.” With a stiff first coat, the mesh bridged without sagging. Larger than that, I’d back the hole with a scrap piece (California patch or a pre-made metal patch) and use the tape to tie in the edges.

Seams: On a tapered factory seam, mesh tape buried nicely. On a butt joint, expect to use a touch more compound than with paper tape because you’re filling the mesh thickness along with building your feather. That’s normal. The upside: zero bubbles, and the mesh helps lock the compound over movement-prone areas.

I tried both setting mud and pre-mixed all-purpose as base coats. Setting compound bonds through the mesh and cures hard, reducing the chance of hairline cracking. Pre-mixed works, but I needed to be more deliberate about pressing the first pass so it keys into the mesh rather than riding on top. Finish coats sanded cleanly without catching on fibers.

Use beyond drywall

The fiberglass is corrosion- and heat-resistant, which makes it suitable for cement board seams and substrate repairs under tile when embedded in thinset. I tested it on a cement board seam in a vanity backsplash area; embedded in modified thinset, it behaved like a standard alkali-resistant mesh tape. A couple of notes:

For shower or wet-area substrates, stick with tape explicitly labeled for cement board and follow the board manufacturer’s instructions. This tape works for light-duty cementitious tasks, but it isn’t a wholesale replacement for specified backerboard tapes in code-critical wet zones.

It can help with minor plaster cracks too, but for historic plaster, consider a plaster-specific system if keys are failing or movement is significant.

I wouldn’t use this tape for HVAC duct sealing or any application where a foil-faced, UL-listed duct tape or mastic is required. It’s not designed for that.

Adhesion in varied conditions

In a climate-controlled room, tack is consistent. In a cooler garage, the adhesive felt slightly less aggressive but still serviceable after warming the wall with a heat gun for a few seconds and wiping off dust. The adhesive’s “repositionable” quality held true: I could lift and restick short runs two or three times before it lost bite, as long as the surface was clean.

Coverage and value

At 150 feet long and 2 inches wide, one roll will:

- Tape roughly 18–20 eight-foot seams, or

- Handle dozens of crack and small-hole repairs throughout a typical room, and

- Leave enough on the roll for future touch-ups.

Because you’re not bedding the tape first, you can move faster on patch runs. The hidden “cost” is an extra skim pass in some situations to bury the mesh profile. That’s the standard trade-off versus paper tape and is worth it when speed and anti-bubble reliability matter.

Where it excels, and where it doesn’t

Strengths:

- Easy, bubble-free seams on flats and butt joints

- Quick crack and small-hole repairs with minimal prep

- Clean edges that don’t fray, reducing finish work

- Repositionable adhesive that avoids stretching the mesh

- Dense fiberglass that resists collapsing into voids

Limitations:

- Requires a bit more compound to fully bury compared to paper tape

- Adhesion is sensitive to dust and chalky paint; surface prep is important

- Not the right choice for inside corners—paper tape is easier to crease and finish

- Not a substitute for foil or mastic on ducts, or for specified cement board tape in critical wet areas

Practical tips from use

Surface prep: Knock off loose paint, vacuum or wipe with a damp cloth, and let it dry. The adhesive needs a dust-free surface to hold during that first coat.

Center your runs: Align the mesh so the grid spans the crack on both sides. Overlap corners by an inch; avoid stacking multiple layers wherever possible to keep build-up down.

Use setting compound for the first coat: A 20- to 45-minute set mud keys through the mesh and reduces callbacks. Switch to lightweight all-purpose for finish coats.

Press, don’t float: Your first pass should push compound through the mesh to the substrate, not glide over it. You’ll feel it lock in.

Feather wide on butt joints: Plan for a final feather of 10–14 inches to hide the build. A wider knife makes this easier.

Store the roll clean: Keep it in a bag or drawer so the adhesive doesn’t pick up dust between uses.

Bottom line

This mesh tape hits the sweet spot I look for in a general-purpose drywall roll: dependable adhesion that isn’t messy, a dense fiberglass weave that resists fraying, and straightforward finishing with standard compounds. It let me move quickly on patch work and delivered stable seams without bubbles or telegraphing once properly buried.

Recommendation: I recommend this tape for DIYers and pros who need a reliable, self-adhesive mesh for drywall cracks, seams, and small-hole repairs, and for light-duty cementitious reinforcement. It’s fast to apply, forgiving to position, and finishes cleanly. You’ll need to respect its limits—prep dusty walls, expect an extra skim in some cases, choose paper for inside corners, and use purpose-made products in wet areas or ducts—but within its lane, it performs exactly as it should.

Project Ideas

Business

DIY Wall-Repair Kits (Ready-to-Sell)

Package the tape with pre-measured joint compound, a small putty knife, sanding pad, and a step-by-step instruction card or QR code to a tutorial video. Sell kits at hardware stores, online marketplaces, or bundles for landlords and Airbnb hosts who need quick fixes. The repositionable, self-adhesive tape is a clear selling point for ease of use.

Mobile Patch & Paint Service for Short-Term Rentals

Offer a rapid-response service targeting Airbnb/property managers for small drywall repairs between guests. Use the mesh tape for fast, durable patches and combine with quick-touch paint. Market by response time guarantees and subscription contracts—small, frequent jobs with low overhead and repeat clients.

Workshops & Online Courses: Small-Scale Plaster Art

Teach in-person workshops or create a paid online course showing techniques for creating decorative wall panels, medallions, and sculptures using mesh tape and joint compound/cement. Sell course bundles that include a roll of tape and tooling (trowel/scraper), and monetize with tiered content, templates, and pattern packs.

Contractor Supply Packs for Tile Installers

Create bulk packs and branded rolls sized/packaged for tile and cement contractors that emphasize the tape's corrosion and heat resistance for cement joints. Offer volume pricing, fast shipping, and an instruction sheet showing best practices to reduce joint failures—position as a premium, time-saving consumable for pros.

Upcycled Home Decor Line

Design and produce small runs of textured wall art, ceiling medallions, and furniture insets made using the mesh tape reinforcement method. Market them as durable, lightweight, custom pieces for modern interiors on Etsy or local galleries. Offer customization (size, texture pattern, finish) and pair with installation hardware and care instructions.

Creative

Textured Relief Wall Panels

Use the mesh tape as a base grid to build low-relief wall panels. Adhere strips of tape directly to a plywood or drywall substrate in a geometric or organic pattern, float several thin layers of joint compound over and sculpt textures with knives and trowels. Once dry, sand and paint or gild. The tape gives strength to thin reliefs and prevents cracking, so panels can be lightweight yet durable.

Mixed-Media Sculptures with Reinforced Skin

Create armatures from wire or recycled frames and cover them with layers of tape and plaster or cement. The fiberglass mesh acts as a flexible, breathable skin that bonds to cementitious mixes, allowing you to make durable garden ornaments, lamps, or modern abstract sculptures that withstand weather and handling.

Custom Decorative Ceiling Medallions

Use the tape to join thin MDF or plasterboard shapes and reinforce the seams before applying finishing plaster. Because the tape is repositionable and heat-resistant, you can fabricate lightweight ceiling medallions and intricate trim pieces in sections, join them seamlessly, and finish with detail work for a high-end look without heavy cast materials.

Mosaic & Tile-Edge Reinforcement Art

When creating small tile or glass mosaic artworks, apply mesh tape to the substrate around edges and over seams before grouting. The tape stabilizes thin-set joints and prevents grout cracking. You can also use exposed strips as a design element—embed small tiles partly over the mesh for an industrial textured border.

Furniture Repair & Decorative Patchwork

Repair holes, cracks, or delaminated veneer on tabletops and cabinets by backing voids with tape, applying a bonding compound or epoxy, then sculpting and sanding to blend. For decorative upcycling, use tape-backed joint compound panels as insets or textured surfaces on cabinet doors and drawer fronts for a rustic or modern finish.