Features

- High-density abrasive grain concentration for faster material removal and lower heat buildup

- Ceramic abrasive formulated to retain sharpness for consistent cutting

- Type 27 wheel profile suitable for grinding applications

- Available in 4-1/2" diameter

Specifications

| Sku | DWAFV84514 |

| Thickness (In) | 1/4 |

| Arbor Size (In) | 7/8 |

| Product Diameter (In) | 4-1/2 |

| Sku | DWAFV84514H |

| Arbor Size | 5/8-11 |

| Thickness (In) | 1/4 |

| Product Diameter (In) | 4-1/2 |

| Sku | DWAFV84518 |

| Thickness (In) | 1/4 |

| Arbor Size (In) | 7/8 |

| Product Diameter (In) | 4-1/2 |

| Sku | DWAFV84518H |

| Arbor Size | 5/8-11 |

| Thickness (In) | 1/4 |

| Product Diameter (In) | 4-1/2 |

| Rpm | |

| Type | Type 27 |

| Manufacturer | DEWALT |

| Product Line | Flexvolt |

Related Tools

Related Articles

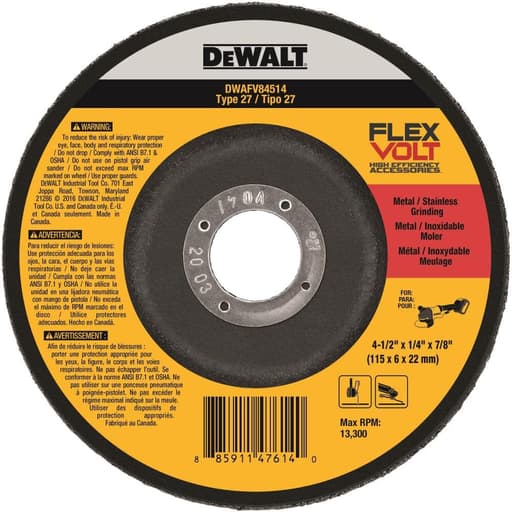

Type 27 metal grinding wheel using a ceramic abrasive with a high grain concentration. Designed to provide sustained cutting performance with reduced heat buildup during grinding.

DeWalt Metal grinding wheel (Type 27) Review

Why I reached for this wheel

I bolted the DeWalt Type 27 wheel onto a 4-1/2" grinder for a week of weld cleanup, beveling, and rusty steel prep, and it quickly became the wheel I didn’t think about—which is exactly what I want from an abrasive. It removes material fast, runs cooler than typical aluminum oxide wheels, and holds its shape well enough that I could focus on the work instead of babysitting the disc.

Setup and compatibility

I tested both arbor styles:

- 7/8" open arbor, which uses the grinder’s standard flange and clamp nut

- 5/8-11 threaded (the “H” variants), which spin on tool-free and save a step

Both seated flat on my grinder’s flange, and the depressed center cleared the guard with no odd interference. If you bounce between corded and cordless, this wheel lives happily on either. It’s part of DeWalt’s Flexvolt accessory line, but it’s a standard 4-1/2" Type 27 grinding wheel and plays nicely with any grinder that supports the size and speed rating. As always, match the wheel to your grinder’s guard and verify RPM ratings on the label.

At 1/4" thick, it’s a true grinding wheel—don’t try to cut with it. The profile and thickness are tuned for face and edge grinding at a moderate angle.

Performance: material removal with control

Ceramic abrasive is the story here. Under pressure, these grains micro-fracture and expose fresh cutting edges, which is why ceramic wheels keep “waking up” instead of glazing over. On mild steel and structural shapes, the wheel dug in decisively without chatter. Weld beads disappeared quickly, and mill scale lifted cleanly without a lot of heat tint.

A few notes from the shop floor:

- Optimal angle: I had the best results at about 15–30 degrees relative to the work surface, using firm, even pressure. Too shallow and you skate; too steep and you gouge.

- Edge stability: The wheel’s 1/4" thickness resisted undercutting and stayed predictable when transitioning from bead to parent metal.

- Vibration: It ran true with no noticeable hop. Balance stayed acceptable as the wheel wore down.

Compared to standard aluminum oxide wheels in the same size, I saw a clear improvement in removal rate per pass and fewer sparks indicating wasted heat. It didn’t transform my grinder into a different tool, but it did make each pass count.

Heat management and finish quality

Even “cooler” grinding still generates heat, but the reduced heat buildup was noticeable on thinner stock. I could blend MIG beads on 1/8" plate without bluing the piece immediately, and the wheel resisted loading on dirty, scaled surfaces. On sheet metal, I still took shallow passes and feathered the edges—this is a fast wheel, and it’s easy to go too far if you lean on it.

The finish it leaves is what I expect from a 1/4" Type 27: aggressive but controllable. For surfaces that need paint-ready smoothness, I followed with a flap disc. For structural work, weld prep, and beveling, the as-ground surface was perfectly serviceable.

Wear and durability

Life is where ceramic earns its keep. The wheel wore evenly and remained sharp for longer stretches than conventional AO wheels in my kit. It didn’t suddenly go “dead”; instead, the cut slowly softened before it was time to swap. I didn’t experience significant chunking or random breakouts at the edge, which speaks to a well-bonded wheel.

One practical note: ceramic shines when you supply enough pressure to keep the grain fracturing. If you’re feathering lightly all the time, you won’t see the lifespan advantage. When I let the wheel work—steady pressure, proper angle—the lifespan was excellent.

Comfort and control

- Sparks: Slightly tighter spark stream than AO, which helps with visibility but still throws plenty—keep the guard on and PPE in place.

- Sound: No unusual whine or resonance, even at full speed.

- Feel: Predictable bite as you load into the work. It “tells” you when you’re at the right angle; the feedback becomes smooth instead of scratchy.

I appreciated the threaded hub version for quick changes, especially swapping between a flap disc and this wheel. If you’re constantly changing abrasives, that convenience adds up.

What it’s best at

- Fast removal of mild and carbon steel

- Weld bead knockdown and blending

- Beveling edges prior to welding

- Cleaning mill scale and heavy rust

What it’s not designed for:

- Cutting: it’s too thick and the Type 27 face isn’t a cutting profile

- Non‑ferrous metals (aluminum, brass): like most hard-bond wheels, it can load quickly; use a dedicated non-ferrous wheel

- Precision finishing: follow with a flap disc or finer abrasive

Comparisons to common alternatives

- Versus aluminum oxide: This wheel removes more material per pass and stays sharper longer, with slightly lower heat input. For short, light-duty jobs on thin material, AO is fine. For sustained grinding or harder steels, ceramic is worth it.

- Versus flap discs: Flap discs leave a friendlier finish and are easier to control on thin stock, but they’re slower for heavy removal. I often start with this wheel for bulk removal and switch to a 60–80 grit flap disc to refine.

- Versus Type 29 (conical) discs: Type 29 flap discs excel at blending; a Type 27 grinding wheel like this is better at flattening and heavy stock removal with the face.

Value and availability

Ceramic wheels typically cost more than AO, but the performance and lifespan even things out. If your work involves frequent weld prep and cleanup, the cost-per-job tracks favorably. The availability of both 7/8" and 5/8-11 versions is practical: choose the hubbed version if you want quick swaps and fewer small parts; choose the 7/8" if you prefer traditional clamping or need cross-brand flexibility.

Tips for getting the most out of it

- Keep the guard on and match the wheel size/type to the guard.

- Use a consistent 15–30 degree angle and steady pressure to keep the ceramic grains self-sharpening.

- Don’t feather excessively—if you need finesse, switch to a flap disc.

- Let the wheel cool between long, heavy passes on thin material to avoid warping and discoloration.

- For non-ferrous metals, switch to a wheel designed for that purpose to prevent loading.

Bottom line

This DeWalt Type 27 wheel hits the mark for heavy grinding on steel. The ceramic abrasive and dense grain pack translate into faster removal, a bit less heat, and a lifespan that outpaces basic wheels. It’s not a one-disc solution—you’ll still want a flap disc for finishing and a dedicated option for aluminum—but for the rough work that actually moves metal, it’s efficient and predictable.

Recommendation: I recommend this wheel for anyone doing regular steel grinding—welders, fabricators, and maintenance techs who need dependable removal without babysitting their abrasives. Choose it for weld cleanup, beveling, and scale removal where you want speed and control. Skip it if your work is mostly thin sheet, non-ferrous metals, or finish sanding; there are better tools for those jobs.

Project Ideas

Business

Mobile weld blend and edge-rounding service

Offer on-site weld flush-grinding, bevel prep, and edge rounding for fabricators, contractors, and property managers. Price per foot of weld or per part; the ceramic wheel’s fast removal and cooler grind improves speed and finish quality on railings, stairs, gates, and structural brackets.

Laser/plasma-cut part finishing for makers

Partner with local cutting shops to handle the finishing stage: remove dross, knock down burrs, radius edges, and blend faces so parts arrive assembly-ready. Bill per batch or per part and differentiate with consistent, heat-free finishes on thin stainless and aluminum-compatible fixtures.

Knife blank roughing and bevel service

Serve custom knife makers by rough-grinding profiles and primary bevels on blanks to target thickness, delivering time savings on repetitive steps. Offer tiered pricing for carbon vs. stainless steels; the ceramic abrasive’s long life keeps margins healthy on batch runs.

Rust scale and coating removal prep

Provide heavy-scale knockdown and surface prep for fences, trailers, fire escapes, and machinery before coating crews arrive. Use the grinding wheel to quickly remove thick scale and weld spatter, then hand off to finer abrasives/painting. Sell as a rapid-turn prep package to property managers.

Architectural metal finishing for designers

Specialize in visible metal components—handrails, table bases, signage frames—delivering flush-blended welds, uniform chamfers, and consistent directional textures. Market a sample board of finishes and charge premium rates for repeatable, heat-tint–free results on stainless and cold-rolled steel.

Creative

Textured metal wall art panels

Use the wheel to carve facets, grooves, and sweeping textures into thin steel or stainless sheet, then blend and feather the patterns across multiple panels. The ceramic grain’s cooler grind helps avoid warping and blueing on thin stock, letting you apply a clear coat to showcase raw metal sheen and directional texture.

Knife and chisel rough-grind

Shape bevels and do fast stock removal on tool steels with consistent bite. The high-density ceramic abrasive stays sharp for even geometry, while the lower heat buildup helps protect temper. Follow with finer abrasives later, but use this wheel to establish primary bevels and clean, straight plunge lines.

Industrial furniture finishing

After welding table bases, shelves, or stools, use the Type 27 profile to blend fillet welds flush, radius sharp corners on tube and plate, and add a uniform, brushed-looking surface. The cooler cut reduces heat tint on stainless accents and keeps edges crisp without glazing.

Garden art and planter fabrication

Create sculptural garden stakes, trellises, and planters by grinding chamfers, scallops, and decorative reliefs into flat bar and plate. Add contrast by selectively removing mill scale and leaving dark areas intact, then seal for an indoor/outdoor raw-metal aesthetic.

BBQ smoker and pit upgrades

Fine-tune door and grate fitment by truing edges, smoothing welds, and easing corners. The wheel’s sustained cutting performance makes quick work of thick weld beads, while lower heat helps minimize distortion on long seams and stainless inserts.