Features

- Zirconia abrasive for increased material removal compared with fiber resin discs (manufacturer cites ~3×)

- Premium abrasive cloth for extended life compared with fiber resin discs (manufacturer cites up to ~15×)

- Type 27 fiberglass backing suitable for grinding at 5–15°

- 5 in diameter with 7/8 in arbor

- 80 grit (medium)

- Coated abrasive construction for metal grinding

- Rated maximum speed: 12,200 RPM

- Pack quantity: 10 discs

Specifications

| Disc Diameter (In) | 5 |

| Grit Size | 80 |

| Grit Grade | Medium |

| Number Of Pieces | 10 |

| Product Pack Quantity | 10 |

| Backing Material | Fiberglass |

| Abrasive Material | Zirconium (zirconia) |

| Abrasive Type | Coated |

| Arbor Size | 7/8 in |

| Speed Rating | 12,200 rpm |

| Applicable Materials | Ferrous metal |

| Color | Dark gray / Yellow |

| Weight | 0.21 lb |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

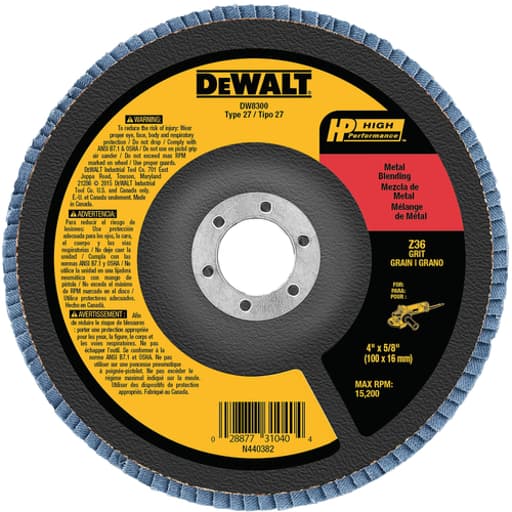

Type 27 flap disc with zirconia abrasive cloth intended for grinding ferrous metals. The disc uses a coated abrasive construction on a fiberglass backing to enable angled grinding (approximately 5–15°). Sold in packs of 10.

DeWalt 5" x 7/8" Type 27 HP Flap Disc (80 Grit) Review

By the third weld on a 3/16-inch bracket, I could tell this DeWalt flap disc wanted to be pushed. It bites with enough enthusiasm to keep a grinder honest, yet it stays composed when you lighten up to blend. If you work mostly in steel and favor a 5-inch grinder, this 80‑grit disc hits a useful middle ground between stock removal and surface refinement.

What it is and how it fits

This is DeWalt’s 5-inch, Type 27 flap disc with a 7/8-inch arbor and zirconia abrasive on a fiberglass backing. Type 27 is the flatter, depressed-center style designed to run at a shallow angle—think 5 to 15 degrees—ideal for blending and controlled grinding. It’s rated to 12,200 rpm, which lines up with most 5-inch grinders. No hub means it mounts directly to the standard flange; no backing pad needed.

I ran the disc on a 12,000 rpm 5-inch grinder with the guard in place. Arbor fit was snug, the disc ran true, and balance out of the pack was good. There’s no chatter or hop, and the fiberglass backing kept things rigid without feeling harsh. The pack comes in tens, which is convenient for shop inventory and keeps the per-disc cost reasonable.

Performance on ferrous metals

This disc is purpose-built for ferrous metals, and that shows. On mild steel plate and angle iron, it removes mill scale and levels small welds quickly. On 1/4-inch fillet welds, I was able to knock down the crown and feather the toe into base metal without digging trenches, provided I kept within that recommended 5–15° window. It’s less grabby at the edges than some more aggressive grits, which helps keep control around corners and on brackets with tight geometry.

Zirconia is the right call here: compared to standard aluminum oxide fiber discs, I got faster cut rates and fewer stalls under pressure. You can lean into it and the grains keep fracturing to expose fresh cutting edges rather than glazing. For general fab tasks—deburring, breaking edges, weld cleanup—the 80 grit is genuinely versatile. If I need heavy hogging, I’ll step down to a 40 or 60 grit flap disc; if I’m chasing a pre-paint finish, I’ll follow with a 120 or a conditioning disc. As an all-rounder, this sits in the sweet spot.

Cut quality, heat, and finish

Kept between 5 and 15 degrees with moderate pressure, the disc leaves a consistent, matte finish that’s easy to prime. One pass around a plasma-cut edge removes dross cleanly without smearing, and I didn’t see the streaky burn patterns you get from overheated aluminum oxide. Heat build-up is controlled as long as you let the disc do the work; if you bury the edge at a steep angle, you can still blue the steel and load the flaps prematurely. That’s operator error more than a product flaw, but it’s worth noting to get the most out of the disc.

I also used it for rust removal on an old trailer frame. The disc cut through scale quickly, though for deep pitting a wire cup is still my first step. After wire brushing, a quick pass with this disc unified the texture nicely without causing excessive thinning.

Wear and durability

DeWalt claims longer life versus fiber resin discs, and in practice I changed discs less often during a normal day in the shop. The flaps wore evenly across the face, and I didn’t see premature shedding or delamination. The cloth backing on the flaps feels “premium” in the sense that it resists fraying when you catch an edge, and the fiberglass plate stayed intact, even after a few hot stops. I ran one disc through several hours of intermittent weld blending and edge breaking on 10-gauge steel; by the end, it still cut respectably, although the finish got slightly finer as the abrasive rounded.

A small thing I appreciated: the disc holds its shape well as it wears. Some flap discs hollow out quickly and get tricky to control; this one stayed predictable, which made it easier to blend flat surfaces to a uniform sheen.

Control and ergonomics

The Type 27 form factor is forgiving. It lets you work flatter for blending without gouging, and the fiberglass backing transmits less harshness to your hands than rigid wheels. Vibration was low; I could run it with a light touch and still maintain contact without chatter. That reduces operator fatigue over a long session and makes finesse work—like feathering around a weld toe—more manageable.

Limitations and what to watch

- Size and arbor: It’s a 5-inch disc with a 7/8-inch open arbor. If your grinder favors 4-1/2-inch discs or uses a hubbed center, check compatibility. The 5-inch format gives a bit more surface speed and life than 4-1/2, but it’s not as common on some jobsites.

- Material scope: It’s intended for ferrous metals. Avoid using it on aluminum or softer non-ferrous materials—you’ll load the disc quickly. For stainless, it cuts fine, but if you’re worried about contamination on a passivated finish, use discs specifically labeled for stainless/INOX service and keep them segregated.

- Grit versatility: 80 grit is a compromise. It does a lot well but doesn’t replace a coarser disc for heavy weld removal or a finer disc for near-finish work. Plan your grit progression accordingly.

- Edge abuse: Like any flap disc, burying the edge at a steep angle shortens life. Keep your angle shallow and spread the contact across the face to maximize durability.

Tips for best results

- Stay in the 5–15° range to exploit the Type 27 geometry. Use the face for blending and the edge only for brief, targeted cuts.

- Let the zirconia do the work. Moderate pressure yields better cut and cooler operation than forcing it.

- Keep your grinder just shy of max rpm if it has variable speed. The disc is rated to 12,200 rpm; on fixed-speed 5-inch grinders at ~12,000 rpm, it’s in the sweet spot.

- Rotate to fresh flaps as you work. A slight change in angle exposes new abrasive and keeps the disc cutting consistently.

- Dedicate discs by material. If you move between carbon steel and stainless, keep separate, clearly marked discs.

Value and pack quantity

Sold in packs of ten, the per-piece cost is competitive for a zirconia flap disc from a pro brand. In my shop, the longer usable life more than offsets cheaper aluminum oxide options that burn out quicker. The pack size makes sense for fabrication outfits and serious hobbyists; casual users may find ten discs a bit much up front, but they store well and you’ll use them if you do regular steel work. The 30-day money-back guarantee is a modest safety net if something isn’t right with a batch.

Alternatives and where this fits

- For maximum removal on thick welds, a 40–60 grit ceramic flap disc will outpace it but at a higher price point.

- For finish-critical work, a 120 grit or non-woven conditioning disc will leave a finer surface ready for paint or powder.

- For tight corners, a smaller 4-1/2-inch disc might offer better access, though you’ll trade off life and contact area.

This DeWalt disc slots in as the general-purpose workhorse for ferrous metal: strong enough to handle weld cleanup, controlled enough to blend, and durable enough that you’re not changing discs every hour.

Recommendation

I recommend this DeWalt 5-inch flap disc for fabricators, welders, and DIY metalworkers who primarily grind carbon steel with a 5-inch grinder. It delivers reliable cut rate, balanced handling, and solid life from its zirconia cloth without fuss. The Type 27 geometry makes it easy to blend without gouging, and the 80 grit is genuinely versatile if you keep a couple of complementary grits on hand for extremes. If you need a single disc to live on your grinder for day-to-day steel work, this is a sensible, cost-effective choice. The only reasons to pass are if you’re locked into 4-1/2-inch consumables, you require INOX-labeled abrasives for stainless-only work, or you’re chasing either maximum removal (go coarser/ceramic) or near-finish surfaces (go finer). For everything in between, it earns a spot in the drawer.

Project Ideas

Business

Mobile Weld Cleanup & Railing Finishing

Offer on-site blending of welds and edge cleanup on railings, gates, and stairs. The zirconia flap disc’s fast cut and long life reduce consumable costs. Charge hourly or per linear foot; upsell priming/clear-coating.

Lawn & Garden Tool Reconditioning

De-rust, sharpen, and balance mower blades; clean and edge shovels, hoes, and axes with the 80-grit disc. Run as a mobile or pop-up service during spring/fall with flat-rate packages and add-on blade balancing.

Custom Steel Furniture Micro-Brand

Produce small-batch tables, benches, and shelf brackets. Use flap discs to achieve production-quality weld blending and brushed finishes without large sanding equipment. Sell via Etsy/local markets with standard SKUs.

Trailer & Utility Frame Refurb Prep

Provide rust removal, weld prep, and edge deburring on ferrous frames, racks, and hitches. Fast zirconia removal accelerates coating jobs; bundle with paint/undercoat application and maintenance plans.

Metal Signs & Brackets Shop

Cut steel signs/brackets (in-house or outsourced) and finish with flap discs to deburr, remove mill scale, and add a brushed aesthetic. Offer powder coat or clear coat finishes and sell to local businesses.

Creative

Scrap-Steel Industrial Wall Art

Assemble patterns from steel offcuts, then use the 80-grit Type 27 flap disc at a shallow 5–15° to remove mill scale, round corners, blend tack welds, and add directional brush or swirl textures before a clear coat.

Upcycled Knife and Tool Tune-Up

Rough-shape knives from old files or springs and establish bevels with the zirconia 80-grit disc, then blend evenly before moving to finer grits. Also rehab chisels, pry bars, and shop tools by de-rusting and smoothing edges.

Garden Sculptures and Planters

Weld simple geometric planters or abstract yard art and use the flap disc to clean welds, soften sharp edges for safe handling, and prep surfaces for patina or paint. The Type 27 profile helps feathering welds smoothly.

Steel-Frame Furniture

Build coffee tables or shelving with angle iron or tube steel. After welding, use the disc to flush and blend joints, knock down spatter, and produce a uniform brushed finish prior to clear coat.

Fire Pit or Smoker Build

After cutting and welding plate or drum parts, clean slag, radius edges, and blend seams with the 80-grit flap disc. Remove rust on reclaimed steel and prep for high-temperature paint.