Features

- Zirconia abrasive for higher material removal rate compared with standard fiber resin sanding discs

- Premium abrasive cloth intended to extend disc life compared with fiber resin discs

- Fiberglass Type 29 backing designed for a 20–25° grinding angle

- Available in multiple grit sizes (including 36, 40, 60, 80)

- Offered in multiple diameters and arbor configurations (examples: 4", 4-1/2", 7"; 5/8" arbor, 7/8" arbor, 5/8"-11)

Specifications

| Abrasive Material | Zirconia |

| Backing Material | Fiberglass (Type 29) |

| Typical Grinding Angle | 20–25 degrees |

| Available Grit Sizes | 36, 40, 60, 80 (varies by SKU) |

| Available Diameters | 4", 4-1/2", 7" (varies by SKU) |

| Arbor Options | 5/8", 7/8", 5/8"-11 (varies by SKU) |

| Maximum Rpm (Example) | 15200 RPM (listed for a 4" variant) |

| Package Quantity | 1 each (as listed for some retailers) |

Related Tools

Related Articles

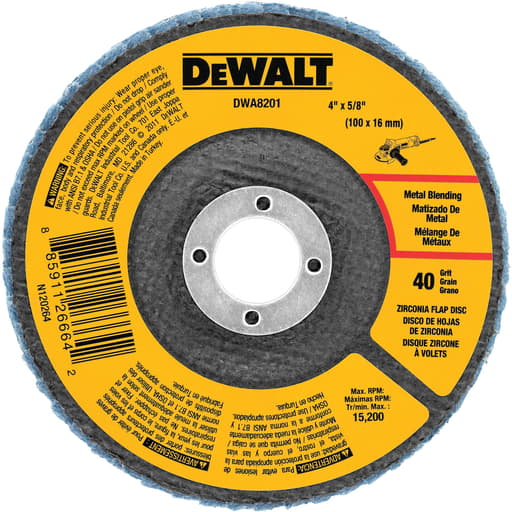

Type 29 flap discs with zirconia abrasive and a fiberglass backing. Designed for angled grinding (approximately 20–25°) and intended for material removal and blending on metal surfaces. Available in multiple diameters, arbor sizes and grit grades.

DeWalt Flap Disc Type 29 Review

First impressions and setup

My angle grinder spends more time with a flap disc than any other accessory, and DeWalt’s Type 29 flap disc has become a steady companion in the shop. I’ve run it on a few grinders—mostly a 4-1/2-inch, 11-amp tool with a 7/8-inch arbor, and occasionally a 7-inch grinder with a 5/8-11 hub. Fitment is straightforward thanks to the multiple arbor options DeWalt offers, and the disc seats flat on the flange with no wobble. The fiberglass backing keeps the weight down and vibration in check, and the conical Type 29 profile is instantly noticeable—designed to be used at roughly a 20–25 degree angle rather than flat.

Before touching steel, I always confirm the disc’s speed rating against the grinder’s no-load RPM. The 4-inch variant I tested is marked at 15,200 RPM max, which matches typical compact grinder speeds. That’s basic safety, but it matters—flap discs don’t tolerate overspeed.

Performance on steel and stainless

Zirconia abrasive is the star here. Compared with the aluminum oxide and resin fiber sanding discs I’ve used for years, this disc cuts faster and stays cooler under pressure. On mild steel plate, a 40-grit disc erased mill scale in a single, controlled pass and knocked down MIG weld beads without smearing. The Type 29 profile lets you lean into the work at 20–25 degrees and engage a broader swath of flaps, which translates into higher removal rates without gouging. If I maintain that angle and keep the grinder moving, I get a uniform scratch pattern that blends fast.

On 304 stainless, the zirconia still bites well. I switch to 60 or 80 grit for weld blending on stainless handrails and brackets. With light-to-moderate pressure, the disc stays sharp, and the backing holds firm as the flaps feather down. Heat build-up is manageable as long as I avoid heavy pressure; stainless punishes any abrasive, but this disc doesn’t glaze over prematurely. I’ve produced finish-ready blends with an 80-grit disc that needed only a Scotch-Brite pass to finish.

Material removal vs. control

Type 29 discs are known for aggressive stock removal and contouring, and this one fits that mold. Edge beveling is quick: on 3/16-inch angle iron, I can cut a clean 1/16–1/8-inch chamfer in a few strokes with a 36- or 40-grit disc. Where it surprised me was control near fillets and on curved surfaces. The conical shape makes it easy to roll into a radius without digging corners or leaving chatter marks. If you’re trying to keep a weld toe clean while blending, this geometry helps.

If I’m chasing absolute flatness on a broad surface, I’ll still reach for a Type 27 disc or a hard wheel. The Type 29’s crown encourages a slight hollow in the center if you bear down in one spot. For blending and shaping, though, the control is excellent.

Durability and disc life

DeWalt’s premium abrasive cloth lives up to the claim of extending disc life over basic resin fiber sanding discs. In the shop, I track usage by task rather than hours, and the 40-grit disc I used for weld cleanup on a small gate project (roughly 12 feet of bead total) still had teeth afterward. What stands out is the predictable wear: the flaps shed uniformly, exposing fresh zirconia without sudden dull spots. The backing stayed intact—no delamination—through aggressive work, which I credit to the fiberglass Type 29 structure.

As with any flap disc, life depends on technique. Light to moderate pressure keeps the abrasive cutting; leaning too hard grinds the backing and overheats the flap edges, shortening life. Used properly, I get noticeably more cut per disc than with economy aluminum oxide flappers.

Grit choices and use cases

I keep a small range on hand, and DeWalt’s lineup covers the essentials:

- 36 and 40 grit: rapid stock removal, beveling, weld knockdown on mild steel

- 60 grit: blending after a heavy pass, shaping brackets, cleaning heat tint on stainless

- 80 grit: final blending prior to finishing, edge prep before paint or powder

For general metalwork, 40 grit followed by 60 or 80 grit gives a clean, paint-ready surface without deep scratches that telegraph through coatings.

Compatibility and sizes

DeWalt offers the disc in multiple diameters (4, 4-1/2, and 7 inches) and arbor configurations (5/8, 7/8, and 5/8-11). That flexibility matters if you maintain a mixed fleet of grinders. The 7/8-inch bore version is the shop standard for my smaller grinders; the 5/8-11 threaded hub on the larger discs is convenient because it eliminates the flange nut. If you’re swapping discs frequently during a project, the threaded option saves a meaningful bit of time.

Aluminum, paint, and non-ferrous metals

This is primarily a steel and stainless workhorse. Zirconia can load on soft non-ferrous metals. It’ll still cut aluminum, but the flaps can clog quickly and smear. If I know I’m spending time on aluminum, I’ll switch to a disc intended for non-ferrous work or use a lubricant stick to minimize loading. For paint and heavy rust removal, the disc works but is arguably overkill for delicate panels; a stripping wheel or a coarser surface-conditioning disc is gentler and preserves more base metal.

Ergonomics and vibration

The fiberglass backing keeps the disc lightweight, and the balance is good. On my 4-1/2-inch grinder, vibration is minimal—even as the disc wears down, it remains stable without the harmonic buzz that cheaper backings sometimes develop. Noise is typical flap-disc noise: a high, even grind rather than the harsh chatter of a hard wheel. With ear and eye protection and a decent respirator, it’s a comfortable day’s work tool.

Tips for best results

- Hold a consistent 20–25 degree angle to engage the Type 29 profile properly; too shallow and you’re skating on the tips of the flaps.

- Use moderate pressure—let the zirconia cut. Excess pressure dulls flaps and heats the work.

- Keep a steady sweep. Dwell marks show up fast with coarse grits.

- Step your grits. A quick progression from 40 to 60 or 80 saves time over pushing a single grit too far.

- Match disc diameter and arbor to your grinder and confirm max RPM on the disc label before use.

- For stainless, lighten your touch and keep the work cool to avoid discoloration.

How it compares

Against standard resin fiber sanding discs, this flap disc wins on nearly every metric: removal rate, control, and disc life. Compared with other zirconia flap discs in the same price bracket, performance is competitive and consistent. The Type 29 geometry will be a plus if you contour and blend often; if your work is mostly flat surface finishing, a Type 27 might be the better fit. I also appreciate that DeWalt’s sizing and arbor options align cleanly with common grinders—no adapter juggling.

Value

Sold individually, the disc sits in the middle of the price spectrum for a branded zirconia flap disc. Considering the lifespan and the finish quality, the cost per job is favorable. I do wish multi-pack options were more commonly stocked locally, as that’s how most shops buy consumables to keep costs predictable.

Limitations

- Not ideal for aluminum or other soft non-ferrous materials without a lubricant or a non-loading formulation.

- Type 29 geometry, while versatile, isn’t the best choice for dead-flat surface leveling.

- As with most flap discs, edge abuse shortens life; if you need to hog material repeatedly on an edge, a hard wheel or a ceramic flap disc might be more efficient.

Bottom line

The DeWalt Type 29 flap disc hits the sweet spot for metal removal and blending on steel and stainless. The zirconia abrasive cuts quickly without overheating, the fiberglass Type 29 backing is sturdy and well-balanced, and the available grits and sizes cover the typical needs of fabrication, repair, and light production. It’s a reliable, predictable disc that rewards good technique and delivers a clean finish.

Recommendation: I recommend this flap disc for anyone doing metal fabrication, welding cleanup, and general shop grinding who wants faster removal and longer life than basic sanding discs. Choose it for beveling, weld blending, and contouring at a 20–25 degree angle, and keep a couple of grits on hand to control finish quality. If your work is mostly aluminum or perfectly flat surfacing, consider a disc tailored to those tasks; otherwise, this one is a solid, day-in/day-out performer.

Project Ideas

Business

Mobile Weld Seam Blending Service

Offer on-site weld cleanup for gates, railings, trailers, and ornamental iron. Market per-linear-foot pricing for weld blending with documented grit progression (40 to 80). Carry multiple disc diameters and arbors (4-1/2" 7/8", 7" 5/8"-11) to fit clients’ grinders. Zirconia’s higher removal rate reduces time on site and increases margin.

Deburr and Edge-Radius Subcontracting

Partner with local laser/plasma shops to handle post-cut deburring, oxide removal, and edge rounding. Standardize finish levels (e.g., ‘Machined Deburr’ 40 grit; ‘Cosmetic Blend’ 60/80 grit) and charge per part or batch. Type 29 discs let you keep a consistent 20–25° contact for uniform chamfers.

Custom Steel Decor and Hardware Shop

Produce hand-finished shelf brackets, handles, wall hooks, and signage. Use 36–40 grit for fast shaping and 60–80 for a refined, sell-ready finish. Highlight ‘hand-blended, durable zirconia-finished’ surfaces in product listings to differentiate from raw, sharp-edged competitors.

Auto/Moto Restoration Finish Work

Provide a service to blend patch panel welds, smooth brackets, and prep custom parts for paint or powder. The zirconia abrasive speeds removal without frequent disc changes, and the fiberglass Type 29 backing helps maintain the correct angle for flat, wave-free blends on panels and frames.

Angle Grinder Finishing Workshops

Run classes teaching safe grinder use, proper 20–25° technique, and grit sequencing for metal finishing. Sell a starter kit (4-1/2" Type 29 discs in 40/60/80 grits with a safety guide). Upsell students on follow-up project days where they finish a small welded piece to take home.

Creative

Reclaimed Metal Garden Sculptures

Turn scrap steel and old tools into garden art by cleaning rust, shaping contours, and blending welded joints. Use 36–40 grit zirconia Type 29 discs at a 20–25° angle for fast material removal and shaping, then switch to 60–80 grit to refine textures and create directional grain that catches light. The conical Type 29 face helps you reach into curves while still working flats.

Industrial-Style Furniture Finishing

Build a steel coffee table base, bench legs, or shelf brackets and use the flap discs to break sharp edges, flush welds, and create a consistent brushed finish. Start with 40 grit for weld blending and step to 60/80 grit for final uniformity. 4-1/2" discs with 7/8" arbor are nimble for tight spots; 7" discs speed up large surfaces.

Layered Metal Wall Art with Grind Patterns

Cut or source steel silhouettes, then ‘paint with the grinder’: lay down radiating or cross-hatch grind patterns for depth and reflective effects. Use 60–80 grit for clean, uniform swirls and switch to 36–40 grit for bolder texture on background layers. The zirconia abrasive cuts cool and holds up when blending large panels.

Custom Fire Pit or BBQ Smoker Finish

After welding a fire pit ring or smoker box, smooth seams, remove heat tint, and radius edges for a professional, safe touch. Type 29’s angled face makes it easy to keep the disc flat at 20–25° for even blending. Progress from 40 to 80 grit for a clean finish that takes high-temp paint well.

Knife Blank Profiling and Bevel Blending

Shape mild-steel practice blanks or decorative blades by hogging off stock with 36–40 grit and refining with 60–80 grit to blend bevels before hand-sanding. The zirconia cloth resists loading and lasts longer than fiber discs, and the Type 29 angle helps control pressure along the bevel line.