Features

- High grade precision ground Carbide tips provide a super fine cutting edge

- Fully Hardened high grade tool steel body for superior performance in heavy load applications

- Advanced sock-tooth technology for maximum tooth support

- Aggressive 25° hook angle for faster cutting

Specifications

| Color | Black |

| Size | 7-1/4" x 24T |

| Unit Count | 1 |

Related Tools

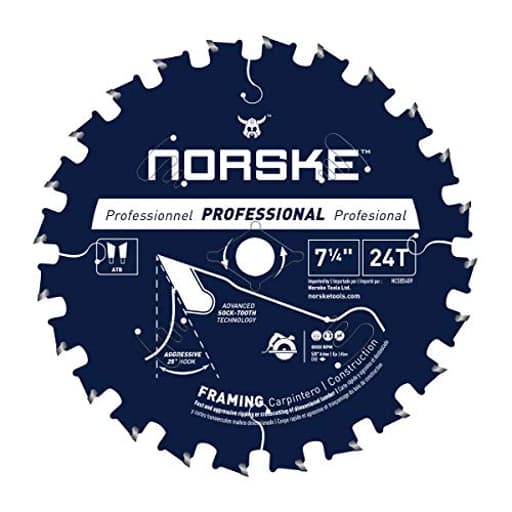

7-1/4" 24-tooth circular saw blade with a 5/8" bore intended for cutting sheet goods, decking, fencing, framing lumber, studs and composite materials. It has precision-ground carbide tips on a fully hardened tool steel body, a sock-tooth design for tooth support, a 25° hook angle for faster cutting, and a laser-cut diamond knockout for arbor adaptation.

Norske Tools NCSBS409 7-1/4 inch 24T Socktooth Ciruclar Saw Framing Blade 5/8 inch Bore with Laser Cut Diamond Knockout for Sheet Goods, Deck & Fence, Framing Lumber, Studs and Composites Review

What I tested and why

For framing and deck builds, a 7-1/4-inch, 24-tooth blade is the workhorse I reach for most. I used the Norske 24T framing blade across a few weeks of mixed work: ripping and crosscutting SPF studs, trimming pressure-treated joists, breaking down plywood and OSB, and making a handful of cuts in composite deck boards and a piece of strand bamboo. I ran it primarily on a corded sidewinder and a worm drive, both with 5/8-inch arbors. I also tested the diamond knockout to confirm fit on a saw that requires it.

This blade is built around a fully hardened steel body, with precision-ground carbide teeth and what Norske calls a sock-tooth design—an enlarged shoulder behind each tip to support the carbide during heavy cuts. It also has an aggressive 25° hook angle aimed at fast feed rates, plus a laser-cut diamond knockout for worm-drive compatibility. On paper, that’s a solid recipe for a fast framing and demolition blade. In the wood, it behaved like one too—mostly in good ways, with a couple of caveats.

Build, setup, and compatibility

Out of the sleeve, the plate was flat and clean, and the teeth were evenly set and sharp. The black finish held up after several days of cutting without obvious resin build-up. Arbor fit on a standard 5/8-inch flange was snug with no slop. The diamond knockout released cleanly with a couple of taps and locked onto a worm-drive arbor without chatter. If you use multiple saws, that knockout saves having to keep different blades around.

The plate feels stout for a 7-1/4-inch blade, and that extra stiffness shows up when the saw is under load. I didn’t detect notable flutter or bell-ringing as the blade exited cuts, which can be a problem on cheaper plates. That stiffness also helps the blade track in long rips.

Cutting speed and feel

The 25° hook angle and 24-tooth count prioritize speed and chip ejection over finish, which is exactly what you want in framing. In 2x SPF and southern yellow pine, the blade pulled into the cut with little push effort. The saw motor never felt overtaxed, even when I leaned on it through wet PT lumber. On the worm drive, the cut had that “self-feeding” feel you get from aggressive hooks—fast, controlled, and predictable as long as you keep the shoe planted and your line of sight clear.

In thicker rips (ripping 2x along the grain), the blade kept its pace and held a straight line without wandering. Crosscuts in studs were crisp with minimal fuzzing on the exit side, and I didn’t hear the teeth chattering on knots. The sock-tooth shoulders likely help stabilize the tips when you hit hard inclusions or switches in grain.

On a cordless saw, the low push effort is welcome. Aggressive hooks can sometimes cost you battery if they grab and stall, but this blade stayed efficient—steady feed, clean chip evacuation, and no bogging in typical materials. If your cordless saw struggles, it’s more about the saw’s torque than the blade.

Sheet goods and composites

On plywood and OSB, a 24T blade is a compromise: fast break-down with some tearout on the face veneer. With this blade, tearout stayed reasonable if I kept the blade depth just past the material thickness and supported the work. For visible cuts, a quick score pass at shallow depth or painter’s tape on the show side gave a cleaner edge. It’s not a finish plywood blade, and it doesn’t pretend to be; used appropriately, it’ll handle sheet goods just fine on site.

Composite deck boards and strand bamboo are dense and abrasive. I made a handful of cuts in each. The blade stayed on line and cleared chips well. Expect a more aggressive bite and some edge fuzzing on composites—again, not a finish blade—but it didn’t burn or smear, and it didn’t slow down to a crawl. If you make a lot of composite or bamboo cuts, you’ll want a higher-tooth, specialized blade; for occasional cuts, this one is serviceable.

Cut quality and accuracy

For framing lumber, the cut quality is what I look for: edges that are square and true, with saw marks light enough not to affect fit-up. In hardwoods (oak and maple offcuts), the blade cut without burning, but you’ll see more pronounced machining marks on crosscuts and a bit of splintering at the exit. That’s inherent to the tooth count and hook angle. If your work involves visible hardwood edges, switch to a 40T or higher.

The blade runs true. I didn’t see runout in my sample—no wavy kerfs or lateral wander. The plate stiffness keeps the kerf consistent through the cut. If you ever do encounter wobble on any blade, it’s often a manufacturing defect or a bent plate; exchange it rather than fighting it.

Noise, vibration, and comfort

Some framing blades ring like cymbals under load. This one stayed relatively quiet and free of high-pitched resonance. I didn’t notice irritating harmonic vibration in the handle, and the saw tone didn’t spike as the blade exited cuts. Less vibration usually means a cleaner edge and better control, and that was my experience here.

Durability and maintenance

After a steady run cutting studs, PT, and a smattering of composite and bamboo, the carbide still felt sharp at the fingertips and continued to feed without me forcing it. That sock-tooth shoulder seems to protect the carbide during accidental contact with hidden fasteners; I grazed one plated screw and lost a micro-chip on a tip but the blade kept cutting fine. As with any blade, pitch will build on the teeth if you spend a day in sappy pine—cleaning with a blade-safe solvent restores performance quickly.

This blade can be sharpened when it dulls; the carbide tips are large enough to survive a couple of grinds. That said, the economics of sharpening a 24T framing blade vary by shop. It’s nice to have the option.

Safety notes

The aggressive hook contributes to speed but also raises kickback potential in certain cuts, especially plunge cuts and when crosscutting narrow stock without full support. Keep both hands on the saw, let the blade spin up fully, and start gently. For sheet goods, set the depth so only a tooth or two clears the bottom—better control and less tearout.

Value and use cases

As an all-around jobsite blade, the Norske 24T framing blade hits the right notes: fast, predictable cutting in construction lumber; acceptable performance in sheet goods with basic technique; and enough durability to stay on the saw through a busy week without turning into a burner. The diamond knockout expands compatibility, and the hardened body keeps the plate behaving under load.

It’s not a fine-finish blade and won’t replace your 40–60T trim blades for visible edges. If your day is mostly cabinetry, look elsewhere. But for framing, decking, fence builds, and general carpentry, this blade feels like a good balance of speed, control, and longevity.

What I liked

- Fast feed rate in 2x material with low push effort

- Plate stiffness that resists flutter and helps track straight

- Carbide that holds up to knots and occasional abrasive materials

- Useful diamond knockout for worm-drive arbors

- Manageable noise and vibration

What could be better

- Tearout on plywood and hardwood crosscuts (expected for 24T/25° hook)

- Aggressive hook can grab on plunge cuts—requires good technique

- As with any mass-market blade, if you encounter runout, swap it rather than trying to true it in the field

Recommendation

I recommend the Norske 24T framing blade for carpenters and DIYers who need a dependable, fast-cutting blade for framing lumber, decking, and general jobsite work. It feeds quickly, tracks straight, and holds an edge through a variety of materials without punishing your saw or your ears. Pair it with a higher-tooth blade for finish cuts and you’ll have most of your circular saw needs covered. If your work skews heavily toward fine plywood or hardwood trim, choose a finer-tooth blade instead; otherwise, this is a solid, cost-effective staple for the tool bag.

Project Ideas

Business

Cut-to-Size Sheet Goods Service

Offer a local cut-to-size service for homeowners and small contractors who need plywood, MDF, or composite panels trimmed to exact dimensions. Market fast turnaround and clean edges—made possible by the blade's precision carbide teeth and hardened body—which reduce on-site labor and sanding costs for customers.

Flat-Pack DIY Project Kits

Design and sell flat-pack DIY kits (shelves, planters, small furniture) with pre-cut parts ready for assembly. The blade's repeatable, clean cuts let you produce consistent kit components in batches. Include easy assembly instructions and finish options; this product suits online marketplaces and local craft fairs.

Mobile Deck & Fence Prep Service

Provide a mobile service that pre-cuts deck boards, fence pickets, and framing pieces on-site or at a shop to exact lengths. The blade is optimized for decking and fence materials and its aggressive hook angle speeds cutting, allowing higher throughput and reduced installation time for contractors.

Custom Millwork for Small Contractors

Specialize in producing small runs of custom trim, sills, and simple built-in components using sheet goods and framing lumber. Emphasize precision and finish quality—benefits of the carbide-tipped, fully hardened blade—so your shop can supply finished parts that save contractors time and improve on-site results.

Upcycled Furniture Line

Source damaged pallets, old decking, and leftover sheet goods to craft a small-batch upcycled furniture line (tables, benches, shelving). The blade's ability to cut mixed materials cleanly reduces finishing work and allows rapid prototyping of designs that you can sell at markets, online, or through consignment stores.

Creative

Floating Shelves from Reclaimed Decking

Use reclaimed deck boards or composite planks to make a staggered set of floating shelves. The 7-1/4" 24T blade's precision-ground carbide tips and sock-tooth design give clean edges on composite decking and hardwoods, minimizing tear-out so the visible faces look factory-fresh. The aggressive 25° hook angle speeds crosscuts and rip cuts for fast production of evenly sized boards.

Geometric Plywood Wall Panels

Cut precise triangles, hexagons, and trapezoids from 1/2" or 3/4" plywood to assemble modern geometric wall art or an accent wall. The blade's fine cutting edge produces smooth faces for staining or veneering, and its hardened steel body handles long sheet cuts without wandering—ideal for repetitive panel work.

Modular Outdoor Planter Benches

Create modular planter boxes that double as bench seating using treated lumber and composite decking. The blade excels on mixed materials—composites, framing lumber, and sheet goods—so you can cut rails, decking tops, and plywood planter liners quickly while maintaining tight joints for a polished look.

Precision Acoustic Slat Panels

Fabricate slatted acoustic panels from thin hardwood or MDF battens mounted to plywood backers. The 24-tooth blade balances fast cuts with a fine finish, reducing sanding time on visible edges. Laser-cut diamond knockout makes it easy to adapt the blade to different saw arbors used in a small shop.

Custom Dollhouses & Playhouses

Cut scaled sheet-goods kits for dollhouses or backyard playhouses—accurate straight cuts and clean edges are vital for tight-fitting joints and painted finishes. The blade's aggressive hook angle and carbide tips let you cut repetitive parts quickly while preserving edge quality for minimal assembly sanding.