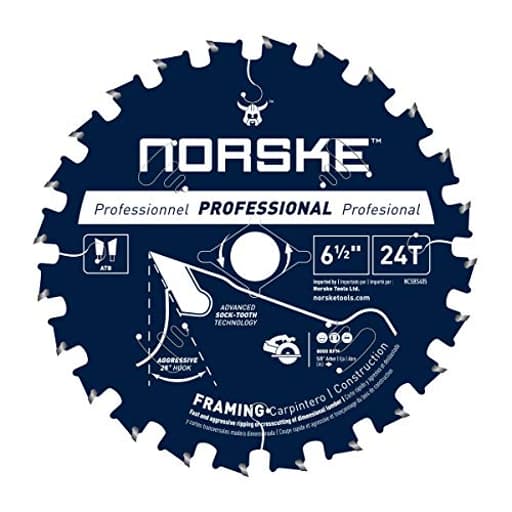

Features

- High grade precision ground Carbide tips provide a super fine cutting edge

- Fully Hardened high grade tool steel body for superior performance in heavy load applications

- Advanced sock-tooth technology for maximum tooth support

- Aggressive 25° hook angle for faster cutting

Specifications

| Size | 6-1/2" x 24T |

| Unit Count | 1 |

Related Tools

This 6-1/2-inch, 24-tooth circular saw blade is designed for cutting framing lumber, studs, decking, fence boards, sheet goods and composite materials. It has precision-ground carbide tips on a fully hardened tool-steel body, a sock-tooth tooth form for tooth support and an aggressive 25° hook angle for faster cutting, and includes a 5/8-inch arbor with a laser-cut diamond knockout for saw compatibility.

Norske Tools NCSBS405 6-1/2 inch 24T Socktooth Circular Saw Framing Blade 5/8 inch bore with Laser Cut Diamond Knockout for Sheet Goods, Deck & Fence, Framing Lumber, Studs and Composites Review

Why I Tried This Blade

Switching blades on compact cordless saws can feel like a game of compromises: speed vs. finish, durability vs. price, compatibility vs. performance. I put the Norske 6-1/2-inch 24T framing blade on a couple of 18V/20V circular saws specifically to see if it could be a go-to for framing lumber, sheet goods, and occasional composite decking—exactly the mix most remodelers and DIYers run into on a typical week.

The headline: it’s a fast, sturdy, jobsite-friendly blade that prioritizes productivity over polish, with a few smart design choices that set it apart in this price range.

Design and Build

Norske leans on a few core ideas here:

- Precision-ground carbide tips: The tips arrive sharp and true. They aren’t oversized showpieces, but they’re consistent and seated cleanly.

- Fully hardened tool-steel body: The plate feels rigid, and under load it resists the flutter you sometimes get with cheaper 6-1/2-inch blades.

- Sock-tooth support: The “sock-tooth” tooth form is built to back up each carbide tip, which in practice helps keep teeth intact during the inevitable incidental encounters with knots or tough grain.

- Aggressive 25° hook angle: This is a framing-forward geometry. It pulls into the cut eagerly, which translates to higher feed rates and less strain on cordless saws.

There’s also a 5/8-inch arbor with a laser-cut diamond knockout. If you need the diamond arbor for certain saws, you can pop it out; otherwise, leave it in place for standard 5/8-inch arbors. The laser-cutting matters—knockouts that are stamped can leave little burrs or induce plate stress. This one is clean.

Setup and Compatibility

On my compact saws with 5/8-inch arbors, installation was straightforward, and the blade ran true right out of the gate. If you do need the diamond knockout, remove it carefully to avoid distorting the bore—once it’s out, you can’t put it back in, and you’ll want a consistent fit.

A quick note on track saws: many use a 20mm arbor, so this blade isn’t a direct swap for those. This is a framing and general carpentry blade for compact circular saws, not a track-saw finish blade.

On the Saw: Cutting Performance

Framing lumber and studs (SPF, treated): This is where the blade feels at home. With the 25° hook angle and 24 teeth, it rips and crosscuts 2x stock with urgency. On my cordless saws, the motor didn’t lug, and I could keep a steady, confident feed rate. Crosscuts in 2x SPF were crisp enough for framing and deck blocking without reaching for a separate finish blade. In wet treated lumber, the blade didn’t wander, and the body stiffness kept it from chattering when I pushed faster.

Sheet goods (OSB, plywood): With OSB, the blade chews efficiently, which is what you want on subfloor and sheathing. On plywood, the 24T count does show its limits if you’re chasing a furniture-grade edge. I got less tearout on the good face by orienting down-cut on the finished side, scoring cuts with a utility knife when it mattered, or using a sacrificial backer. For cabinet faces or veneered ply, I’d move up to a higher-tooth-count blade; for jobsite plywood tasks, this Norske is perfectly serviceable and quick.

Decking and fence boards: In cedar and pine fence boards, cuts were clean and quick. Composite decking demands a steady feed to avoid melting or fuzz at the edges. The blade’s tooth support helps keep the carbide seated, and I didn’t see chipping in typical composite boards, though resin buildup is a reality with composites—wipe the blade down periodically to maintain performance.

Hardwoods: The blade will get through oak and maple without drama, but it’s not a finish blade. Expect some saw marks on crosscuts and rips, especially if you’re moving quickly. If your day involves hardwood trim or furniture parts, keep a 40T–60T blade in the kit.

Speed, Smoothness, and Vibration

The combination of the aggressive hook and the hardened plate produces a confident, fast cut feel. There’s a noticeable reduction in drag versus some bargain blades I’ve used, especially in thick 2x material. Vibration control is good for a 6-1/2-inch, 24T blade. It’s not whisper-quiet—few framing blades are—but it runs with a composed hum rather than a harsh whine when the saw is tuned and the shoe is supported. That translates into straighter lines and less fatigue.

If you ever sense wobble or see scalloping you can’t blame on technique, check for debris on the flanges, confirm the arbor nut torque, and spin the blade by hand to spot any plate irregularity. Mine tracked straight; if yours doesn’t, swap it early rather than fight it.

Cordless Efficiency

This blade is well suited to battery-powered saws. The 24T count and hook angle let the motor stay in its sweet spot, and I found I could make a long series of crosscuts in 2x stock without triggering thermal limits. For repetitive framing or decking jobs where runtime matters, that efficiency is a real advantage over finer-tooth options that bog the saw.

Durability and Maintenance

The carbide held its edge through a mix of framing lumber, OSB, and composite cuts, and the body stayed flat. The sock-tooth support does what it claims: it seems to help prevent premature tooth loss when you hit a knot or a fastener you missed. That said, any carbide blade will lose teeth on nails or screws, so scan your cuts when you can.

Two maintenance tips:

- Clean pitch and resin regularly. A quick soak and wipe-down restores a lot of “like-new” bite.

- Let the blade do the work. The hook angle is aggressive; forcing the cut can heat up the plate and dull the edge faster than necessary.

If you’re inclined to resharpen, the carbide size will allow a professional sharpening. I didn’t need to sharpen during my test period; cleaning alone brought the performance back when it started to feel a bit grabby.

Where It Excels—and Where It Doesn’t

Strengths:

- Fast, confident cuts in framing lumber, studs, and OSB

- Good control and low vibration for a budget-friendly blade

- Solid performance on cordless saws with noticeable runtime benefit

- Thoughtful compatibility thanks to the laser-cut diamond knockout

Trade-offs:

- A 24T blade won’t give you finish-grade edges on veneered plywood or hardwoods

- Not designed for track saws or fine carpentry where splinter control is critical

- Composite cuts require a light touch and blade cleaning to avoid buildup

Buying Advice

If your work is mostly framing, deck building, rough carpentry, or general remodeling with a compact saw, this Norske 24T is an easy addition to the kit. Keep a higher-tooth-count blade on hand for finish passes, but let this one do the heavy lifting. For the price, the cut quality, speed, and plate stability are impressive.

A few practical tips to get the most out of it:

- Use the right blade depth—about one tooth below the work—to minimize tearout and improve control.

- For plywood, score the cut line or use painter’s tape on the show face when appearance matters.

- Don’t remove the diamond knockout unless your saw specifically needs it.

- Clean the blade periodically; resin is the enemy of smooth, cool cuts.

Recommendation

I recommend the Norske 6-1/2-inch 24T framing blade for anyone who wants a fast-cutting, durable general-purpose option for compact circular saws. It hits the sweet spot for jobsite work: quick through 2x stock, composed on OSB, capable on decking and fence boards, and tough enough to stay sharp across a variety of tasks. It won’t replace a fine-finish blade for cabinetry, but as a primary blade for framing and remodeling, it offers strong value and reliable performance.

Project Ideas

Business

Custom Cut Service for DIYers

Offer a local service that takes customers’ dimensions and delivers pre-cut boards and sheet goods ready for assembly. Market the clean-edge advantage of your carbide-tipped blade (less sanding/trim required) and a quick turnaround for small renovation projects.

Mobile Deck & Fence Repair Business

Operate a mobile unit that replaces or repairs deck and fence boards on-site. The blade is optimized for decking, fence boards and framing lumber—promote fast, clean cuts on composites and treated lumber so repairs look professional and fit precisely.

Subscription DIY Project Kits

Create monthly kits (floating shelf, planter box, cornhole set, small table) with all parts pre-cut and labeled. Use the blade to mass-produce consistent, ready-to-assemble components; sell kits online and include digital plans and short assembly videos.

Workshops & Online How-To Content

Run paid hands-on classes or produce video tutorials teaching safe circular saw technique, material selection, and finish tips using this blade. Monetize through ticket sales, sponsorships, affiliate links to the blade/tool, and by selling plans or cut lists to attendees.

Creative

Floating Shelves with Hidden Brackets

Use the 6-1/2" 24T blade to cut clean, precise shelf blanks from hardwood or birch plywood. The precision-ground carbide tips and sock-tooth design reduce tearout on veneers so your shelf edges stay crisp; the aggressive 25° hook angle lets you rip multiple pieces quickly for a consistent set.

Compact Outdoor Planter Boxes from Composite Decking

Cut composite decking and pressure-treated framing to size for durable, weatherproof planter boxes. The hardened tool-steel body and carbide tips hold up to abrasive composite material, making fast, repeatable cuts for multiple planters without dulling quickly.

Custom Corbels & Stair Accent Pieces

Produce small architectural accents—corbels, bracket supports, and stair tread risers—from framing lumber and dimensional stock. The blade’s aggressive hook angle speeds crosscuts and bevels so you can batch-produce matching pieces for a rustic or modern look.

Plywood Wall Art & Geometric Panels

Cut precise geometric shapes and inlays from sheet goods for modern wall art or headboards. The 24-tooth configuration balances speed and finish, and the sock-tooth technology minimizes splintering on plywood and veneered panels for ready-to-finish pieces.