Features

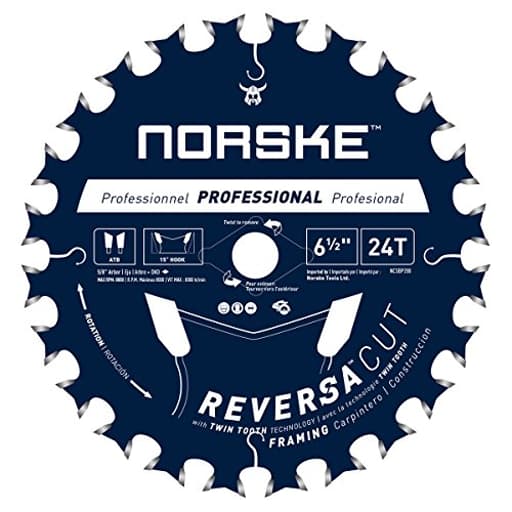

- 6-1/2 Inch x 24T

- The ultimate framing blade complete with revolutionary TWIN TOOTH Technology

- Radical Bi-directional Tooth Profile doubles the blades cutting life

- Specially designed for ripping & cross cutting dimensional lumber

- C3 micro-grain carbide tips precision sharpened on all sides (Top / Face / Sides) for more precise cuts and longer cutting life

- Manufactured from Japanese Tool Steel for true and straight cuts

- Laser Cut Plate & Expansion Slots

Specifications

| Color | Black |

| Size | 6-1/2" x 24 Teeth |

| Unit Count | 1 |

Related Tools

This 6-1/2-inch, 24-tooth circular saw blade is designed for ripping and cross-cutting dimensional lumber, sheet goods, decking, fencing, studs and composite materials. It uses a bidirectional twin-tooth profile with C3 micro-grain carbide tips precision-sharpened on top, face and sides, and features a 5/8-inch diamond knockout bore, laser-cut plate and expansion slots, and a Japanese tool steel body for straight, stable cuts and extended tip life.

Norske Tools NCSBP288 6-1/2 inch x 24 Teeth Reversa Cut Framing Saw Blade 5/8 inch DIAMOND KNOCKOUT Bore One Blade Double Life Time for Sheet Goods, Deck & Fence, Framing Lumber and Studs & Composites Review

A twin-tooth experiment on a 6-1/2-inch framing blade

I put the Norske 6-1/2-inch reversible 24T framing blade through a full week of deck framing, subfloor repair, and general jobsite cutting on a couple of cordless sidewinders and a corded saw. Its calling card—bi-directional “twin tooth” geometry you can flip for a second cutting face—promises longer life and fewer blade changes. In practice, it’s a clever idea with clear strengths, but also some trade-offs you should understand before you swap out your go-to 24T.

Setup and first impressions

Out of the package, the blade is flat and true. The Japanese tool steel plate is well-finished, with clean laser-cut expansion slots and no obvious runout. The 5/8-inch bore with diamond knockout is a nice compatibility touch; on my saws I left the knockout intact for a standard round arbor and had no seating issues.

The carbide is C3 micro-grain and appears evenly brazed, with top, face, and side grinds that are crisp and consistent. This isn’t a rough-and-ready demolition blade; the grind work suggests Norske aimed for a balance of speed and control rather than a pure beater.

Mounting is standard, but you do have to think about orientation. The twin-tooth profile is designed to cut in either direction, so when one side dulls, you can flip the blade on the saw to use the opposite cutting faces. It’s not a gimmick—the geometry actually supports it—but it introduces some behavior differences compared to a conventional 24T.

Cutting performance in dimensional lumber

I started in pressure-treated 2x framing. Crosscuts were straight and reasonably clean for a 24T. In fresh, wet PT, the blade tracked well but wanted a steadier hand than my typical single-direction framing blades. Feed rate was modest; if you push the cut, the blade lets you know by loading the motor and warming up faster than expected.

Rips in PT 2x6 took noticeably more effort compared to a thin-kerf, single-direction 24T. The twin-tooth shoulders create more contact in the kerf, and you feel that as increased drag. My corded saw didn’t care much, but the difference is obvious on an 18V saw: plan on slower feed and more battery draw for continuous ripping. On dense knots, I could hear the motor work harder and the blade tone rise.

On SPF framing lumber, the blade felt happier. Crosscuts had minimal tear-out on the exit side, and rips were smoother with less bogging. If your day-to-day is standard framing stock (not soaked PT), the Norske’s pacing is perfectly serviceable.

Sheet goods and composites

In 3/4-inch OSB and plywood, the blade was surprisingly tidy. The triple-ground carbide and stable plate make straight-line cuts easy to control, and I didn’t see the chatter I half-expected from a reversible tooth. Score cuts were sharp, and full-depth cuts left a clean edge you wouldn’t be embarrassed to leave exposed on a utility surface.

Composite deck boards were a mixed bag. The blade resisted gumming better than average and cut true, but again, feed rate lagged behind a dedicated composite or fine-finishing blade. If you live in composite all day, you’ll be faster with a purpose-built tooth geometry. If you just need to step through a bundle or two during a framing day, the Norske is “good enough.”

Cut quality and feel

- Accuracy: The laser-cut plate stays stable and the blade returns to the line well, provided you don’t force the cut. For plunge starts in subflooring, it was predictable and didn’t yaw.

- Finish: For a 24T, edges are respectable. Expect framing-grade finish with less fuzz than the cheap bulk blades, but not cabinet-saw smoothness.

- Noise: Louder than my usual 24T. There’s a higher-pitched whine that becomes more pronounced under load. Ear protection is always a must, but with this blade it’s non-negotiable.

- Vibration: Low at proper feed rates. Push it, and the extra kerf friction shows up as a slight buzz and heat.

Durability and the “flip” factor

This is where the design earns its keep. After a couple of days of cutting PT and OSB, the blade started to feel dull—nothing catastrophic, just that creeping increase in feed resistance. Flipping the blade restored a big chunk of the original bite. I wouldn’t call it exactly “two blades in one,” but it’s close enough to matter on a job where downtime is money. The fresh face didn’t feel identical to new, but the improvement was obvious.

As for impact resistance, the carbide is sharp and hard but not demolition-grade. I chewed through a bit of subfloor with hidden fasteners; an occasional brad left cosmetic dings with no functional impact. Hitting a ring-shank nail at speed chipped a couple of teeth and introduced minor vibration. If your task is nail-heavy demo, use a dedicated demolition blade. This Norske is a framing blade with a durability trick, not a rescue blade.

Power draw and runtime

On an 18V 6-1/2-inch sidewinder with a 5.0Ah pack, the Norske shortened runtime compared to a standard thin-kerf 24T. It’s not a small difference during continuous rips—battery swaps come sooner, and the saw feels more labored when you get aggressive. On a higher-voltage platform or a corded saw, the downside mostly disappears, and the reversible design becomes a much more appealing value proposition.

If your workday is dominated by cordless ripping in wet PT, you’ll feel the penalty. If you mostly crosscut or use a corded setup, the penalty is modest.

Safety and handling notes

- Let the blade set the pace. The twin-tooth geometry dislikes being forced and will reward patience with straighter, cooler cuts.

- Support your work and keep the kerf clear. The extra side contact means pinch points are less forgiving if the material closes on the blade.

- Check orientation before each install. Flipping to a fresh cutting face is the point, but don’t assume—you want the designed cutting faces leading the rotation.

What I’d change

- Reduce drag: A slightly thinner kerf or a subtle tweak to side relief could preserve the reversible concept while easing the workload on cordless saws.

- Tame the noise: The tone under load is sharp. Different slot patterns or dampers could make the blade friendlier on the ears.

- Publish kerf and hook specs: Pros care about these numbers, especially for cordless optimization and cut behavior expectations.

Who it’s for

- Framers and remodelers who want fewer blade changes and can benefit from “flip to fresh” during a long day.

- Crews running corded saws or higher-voltage cordless platforms where the extra drag is a minor issue.

- Users who cut a mix of framing lumber and sheet goods and value decent cut quality from a jobsite-tough blade.

Who should look elsewhere:

- Anyone prioritizing maximum cordless runtime or fast ripping in wet PT.

- Finish-focused users or those working primarily in composites or hardwoods.

- Demo-heavy workflows with frequent fastener strikes.

The bottom line

The Norske blade brings a smart idea to a 6-1/2-inch framing format and largely delivers on its promise of extended service life. It cuts straight, holds up well through typical framing and sheet-good tasks, and the ability to flip to a fresh cutting face is genuinely useful. The trade you make is efficiency: it’s noisier than average and demands more power, especially evident on 18V saws during sustained ripping or in wet stock.

Recommendation: I recommend this blade for pros and serious DIYers who value uptime and run corded or higher-voltage cordless saws, or whose work skews toward crosscutting and general framing rather than heavy ripping. If you rely on 18V runtime, need the fastest feed through wet PT, or want the quietest, smoothest feel, a high-quality single-direction thin-kerf 24T will serve you better.

Project Ideas

Business

Mobile Deck & Fence Repair Service

Start a local service specializing in small-deck repairs, composite board replacement and fence repairs. The blade’s long life (twin-tooth design) and clean cuts for decking/composites reduce downtime and consumable cost, letting you complete more jobs per day. Market via local ads and optimized Google Business Profile.

Custom Shelf & Wall-Storage Shop

Produce and sell made-to-order floating shelves, media consoles and wall-storage units online and at craft markets. The precision cutting and long-lasting carbide tips let you batch-cut parts quickly with minimal finish work, increasing throughput and margins for small-scale production.

On-site Framing & Trim Subcontractor

Offer short-run framing and interior trim services to builders and remodelers. The blade is built for ripping and cross-cutting studs, sheet goods and trim materials—its straight cuts and heat control mean fewer callbacks and faster install times. Position yourself as a reliable, quick-turn subcontractor.

Upcycled Furniture Line

Create an upcycled furniture business converting pallets and salvaged lumber into benches, tables and planters. The blade’s versatility across dimensional lumber and sheet goods allows efficient processing of inconsistent reclaimed materials, improving product quality while keeping material costs low. Sell via Etsy, Instagram and local boutiques.

Weekend Workshop Classes

Run hands-on beginner carpentry classes (how to use a circular saw safely, basic cuts, building a shelf or planter). Use the blade to demonstrate efficient, clean cutting on common materials; charge per attendee and sell small project kits plus branded blades or safety gear as add-ons.

Creative

Slim Floating Shelves from Plywood

Use a circular saw with this 6-1/2" 24T framing blade to rip and crosscut plywood and hardwood face boards for slim, ultra-straight floating shelves. The laser-cut plate and expansion slots reduce vibration for clean edges, while the carbide tips keep the cuts crisp for minimal sanding. Make several widths and stain/paint for a coordinated wall display.

Composite Deck Planters and Bench

Build weatherproof planters and a coordinating bench using composite decking and dimensional lumber. This blade is designed for composites and decking, so you can make repetitive, accurate crosscuts and rips quickly. Use pocket-screws and hidden fasteners for a professional look; the twin-tooth profile extends blade life through many boards.

Reclaimed Wood Console Table

Create a rustic console table using reclaimed studs and sheet goods. Rip reclaimed planks to consistent widths and resaw plywood top elements with clean, straight cuts enabled by the Japanese tool steel body and precision-sharpened carbide tips. Combine hand distressing with precise joinery for contrast.

Portable Workbench / Jobsite Saw Cart

Design and build a lightweight, fold-flat workbench and saw cart that fits a circular saw using this blade. Cut the top and supports from dimensional lumber and sheet goods; the stable cuts and reduced heat (expansion slots) keep accuracy up when you’re setting up quickly on site or in a small garage.

Outdoor Pet Steps or Ramp

Make a durable outside ramp or tiered steps for pets using decking boards and studs. The blade’s precision on both rip and crosscuts makes it easy to produce repeatable parts for consistent rise/run. Finish with non-slip tape or treads for safety.