Features

- 600 lb clamping force

- 2-piece clutch lock for secure locking

- 2.5 in throat depth

- Ergonomic quad‑lobe bi‑material handle

- Limited lifetime warranty

- Maximum opening: 6 in

- Jaw width: 2.5 in

Specifications

| Clamp Type | Bar |

| Clamping Strength (Lb) | 600 |

| Throat Depth (In) | 2.5 in |

| Jaw Width (In) | 2.5 in |

| Maximum Opening (In) | 6 in |

| Handle Type | Ergonomic, quad‑lobe, bi‑material |

| Material | Multi‑Surface |

| Manufacturer Warranty | Limited Lifetime Warranty |

Related Tools

Related Articles

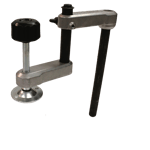

Medium-duty 6 in bar clamp intended for general clamping tasks. Provides up to 600 lb of clamping force, uses a two-piece clutch lock to secure the position, and has a 2.5 in throat depth. The handle is a quad‑lobe bi‑material design to improve grip and torque. Includes a limited lifetime warranty.

DeWalt 6 in Bar Clamp Review

Why I reached for this 6-inch clamp

Small and medium glue-ups are where a shop earns its keep, and a reliable 6-inch bar clamp is one of those quiet essentials that either makes those tasks smooth or maddening. I picked up this DeWalt 6-inch clamp specifically to cover the gap between quick-grip style clamps and heavier parallel clamps. After several weeks of use on edge banding, face frames, small boxes, and general bench work, I have a solid sense of what it does well and where it runs out of runway.

Build and ergonomics

The first thing I noticed is the handle. The quad‑lobe, bi‑material grip isn’t a gimmick; it provides a comfortable purchase that lets me drive meaningful torque without shredding my palm. On smaller clamps, handle shape often dictates how much real clamping pressure you can apply before your hand taps out. Here, the lobes index naturally, especially with light gloves, and it’s surprisingly easy to dial in that last quarter-turn.

The jaws are 2.5 inches wide with a 2.5-inch throat depth. That footprint keeps the clamp stable on an edge without feeling bulky, and the shallow throat is a double-edged sword: you get good control near the edge, but you won’t reach deep into casework or wide panels. The bar and clutch mechanism feel purposeful. The two‑piece clutch lock engages positively as you slide the moving jaw, and it hasn’t popped loose unexpectedly on me. The jaw faces on my main sample arrived with protective pads fitted snugly; they prevent marring on most finished surfaces. I did have a second unit show up without the pads installed, which is more a packaging/QC quirk than a design flaw, but it’s worth checking before you leave the store or start a glue-up.

Clamping force and control

Rated at up to 600 lb, the clamp lands firmly in the medium-duty camp. In practice, it generates more than enough pressure for typical woodworking joinery—edge-to-edge panels, pocket-screw reinforcement, miters with cauls—without the flex and chatter you get from bargain F‑style clamps. It’s not a replacement for a parallel-jaw clamp when you need absolute panel flatness, but for most glue-ups in the 6-inch class, it’s plenty.

The control is what stands out. The clutch gets you into the neighborhood quickly, and the screw handle lets you fine-tune pressure with good feedback. I can feel squeeze-out starting and stop before I telegraph clamp marks into a softer species. The jaw faces stay reasonably parallel under load, and even when I push harder near the upper end of what I’d consider appropriate for a small glue-up, the bar doesn’t telegraph noticeable twist.

Locking mechanism and reliability

Clutch-style bar clamps live or die on how reliably the plates grab the bar. This one’s two‑piece clutch has crisp teeth and a confident bite. It holds its position when you release the handle to grab a mallet or reach for a square—no creeping backward. One housekeeping tip that helps: keep the bar clean. Any dried glue, oil, or dust on the bar can reduce friction and encourage slip on any clutch clamp. A quick wipe-down and the occasional pass with a Scotch-Brite pad have kept engagement consistent.

Size, reach, and real-world tasks

With a 6-inch maximum opening and a 2.5-inch throat, this is a clamp you reach for when the work is close to the edge. It excels at:

- Edge banding shelves and small tops

- Face frames and drawer assembly

- Picture frames and small mitered boxes with cauls

- Holding guides and stops on the bench or drill press

- Light fixture mounting and general-purpose holding during layout

Where it’s less ideal: clamping across a carcass, spanning wide shelves, or any situation that needs deeper reach. That’s not a flaw—just a size limitation. In a typical shop, I’d want at least four of these as a fast, strong utility option, with a set of 12-inch and 24-inch clamps to cover larger assemblies.

Jaw pads and surface protection

On my primary clamp, the pads grip well and resist slipping. They’re firm enough to transmit pressure but soft enough to avoid dents on pine and poplar. If your clamp ships without pads or they go missing in the shop (it happens), you can get workable protection by adding thin cork or leather with double-sided tape, or using a scrap caul. For glue-ups where alignment matters, I prefer cauls anyway; they spread pressure, help maintain squareness, and keep pads free of stray glue that can reduce grip.

Durability and warranty

Over time, what usually kills a bar clamp is either stripped threads, a bent bar, or clutch teeth that round over. After a steady diet of medium-duty tasks, the screw threads still feel smooth, the bar remains straight, and the clutch teeth show no polishing. The limited lifetime warranty is a welcome backstop. In my experience, DeWalt stands behind these hand tools, but you’ll likely know within the first few uses if your particular clamp has an issue (for example, missing pads or a sticky clutch). Inspecting it early is the best way to leverage that coverage.

Speed vs. precision

Compared to trigger-style clamps, this bar clamp is slower in pure on/off speed but far more controlled when you need real pressure and alignment. Compared to heavier parallel clamps, it’s smaller, lighter, and easier to maneuver for quick setups—but it won’t flatten a wide panel on its own. In other words, it fills that middle ground nicely: fast positioning via the clutch, deliberate tightening via the handle, and stable jaws that don’t fight you.

Tips for getting the most out of it

- Keep the bar clean and dry; wipe away glue promptly to preserve clutch grip.

- Add cauls for alignment and even pressure on delicate or wide workpieces.

- Alternate clamps top and bottom on edge glue-ups to minimize bowing.

- Don’t overtighten when a snug fit will do; let well-fitted joinery carry the load.

- Check that jaw pads are present and seated fully before clamping finished faces.

What I’d change

The 2.5-inch throat depth is fine for most tasks in this class, but a hair more reach would broaden its utility without bumping it into a heavier category. I’d also like to see pads packaged in a way that makes them impossible to miss or misplace—minor, but it matters when you’re clamping finished stock. Lastly, a touch more texture on the handle could help in sweaty conditions, though the quad-lobe shape already does most of the ergonomic heavy lifting.

Value and who it’s for

This clamp makes the most sense for woodworkers and DIYers who need reliable pressure and control in tight quarters: cabinet builders for face frames, furniture makers for small assemblies, and general users who are tired of quick clamps running out of steam. If your work skews toward large glue-ups, you’ll still want bigger parallel or pipe clamps, but these 6-inch units are the ones you’ll reach for daily between the big jobs.

Recommendation

I recommend this DeWalt 6-inch clamp. It combines meaningful clamping force (up to 600 lb) with a secure two‑piece clutch, a comfortable and torque-friendly handle, and practical dimensions for day-to-day shop tasks. The limited lifetime warranty adds confidence, and aside from a minor pad-related packaging hiccup on one unit I handled, performance has been consistent and trustworthy. If you’re building out a clamp lineup, start with a handful of these for small to medium assemblies—they strike the right balance of speed, control, and value.

Project Ideas

Business

Mini Cutting Boards and Trays

Produce small-batch 5–6 in charcuterie boards, tea trays, and bread boards. The clamp’s 600 lb force and secure clutch make repeatable glue-ups fast and accurate. Batch in sets, finish with food-safe oil, brand with a logo, and sell at markets and online with custom engraving upsells.

Mobile Chair and Small Furniture Repair

Offer on-site re-gluing of loose chair rungs, stretcher repairs, and cabinet touch-ups. The 2.5 in throat depth is ideal for most chair parts, and the compact 6 in clamp fits tight spaces. Package fixed-price services per joint and add seasonal tune-ups for repeat business.

Custom Picture Framing Service

Build and sell made-to-order frames for art prints and photos. Use the clamps for precise miter glue-ups and spline reinforcement. Offer tiered pricing with different woods and finishes, plus matting and glass. Fast turnaround and perfect corners become your differentiator.

Corner Blocks and Cauls Kit

Design and sell small clamping accessories—45° corner blocks, soft-face pads, and straight cauls—bundled with or sized for 6 in bar clamps. Demonstrate how they improve glue-ups and upsell as a starter kit to hobbyists and makerspaces.

Hands-On Glue-Up Workshops

Host beginner classes on box making, frame building, and panel glue-ups. Provide students with a clamp to use during class and an option to purchase afterward. Monetize via tuition, materials fees, and tool bundles featuring the clamp’s lifetime warranty as a value add.

Creative

Precision Picture Frame Corners

Build a simple miter clamping jig with 45° corner blocks and use the 6 in bar clamp to glue perfect frame corners. The 2.5 in throat depth reaches typical frame stock, the two-piece clutch lock holds alignment while you pin or spline the joint, and the ergonomic handle helps dial in pressure without twisting the frame out of square.

Striped End-Grain Coasters

Glue up narrow hardwood strips into a 5–6 in wide panel using cauls and a pair of 6 in bar clamps, then crosscut into end-grain coasters. The 600 lb clamping force ensures tight seams with consistent squeeze-out, and the compact size makes it easy to stage several glue-ups on a small bench.

Keepsake Jewelry Box

Cut 1/2 in stock with 45° miters and glue a small 4–6 in box. Use the clamp in opposing pairs on each corner to maintain square. The clutch lock prevents creep during cure, and the 2.5 in jaw width spreads pressure; add scrap pads to avoid marring figured woods.

Veneered Art Tiles

Press veneer onto 5x5 in MDF tiles with wax paper and rigid cauls, distributing several 6 in clamps across the panel. The even, high pressure minimizes bubbles and telegraphing without a vacuum bag, creating lightweight wall art or sample swatches.

Bent-Lam Drawer Pulls

Laminated thin strips around a small form to create curved drawer pulls or handles. The 6 in opening suits compact forms, and the quad‑lobe handle makes incremental tightening comfortable while the two-piece clutch holds the bend throughout the cure.