Features

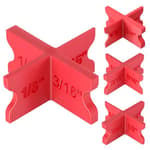

- Dimensions: Screw Diameter .195" - Head Width 0.266" - Head Height .133" Use T20 Torx/Star Diver Bit

- 10 Degree Diminishing Head and Reversing Threads to Prevent Mushrooming

- Dual Threaded (fine/coarse) Assists With Cutting Through Fibrous Decking Material

- Type 17 Tip for Fast Starts, Helps Eliminate "Walking" and Easier Installation without Pre-Drilling

- Uses Include Cap Stock, PVC and Composite Decking, Composite Fascia and Composite Railing

Specifications

| Color | WALNUT |

| Size | WALNUT 1 POUND ~130 SCREWS |

| Unit Count | 130 |

Related Tools

These 1-3/4" exterior-coated composite decking screws (approx. 130 per pound) are designed for fastening cap stock, PVC, composite decking, fascia, and railing to pressure-treated and ACQ lumber. They use a T20 Torx drive with a Type 17 tip for fast starts and reduced walking, dual fine/coarse threads to cut fibrous material, and a 10° diminishing head with reversing threads to minimize mushrooming.

Jake Sales 10 x 1-3/4" Walnut Composite Decking Screws. Exterior Coated, Pressure Treated and ACQ Lumber Compatible. Use T20 Torx/Star Dive Bit - 1 Pound ~130 Screws Review

Why I reached for these screws

Composite fascia and PVC trim can make even a careful installer look sloppy if the fasteners mushroom the surface, wander on start, or strip under torque. On a recent fascia and skirt-board refresh, I ran a pound of Jake Sales composite screws in the walnut color through cap-stock decking fascia and PVC—into pressure-treated framing—specifically to see how their thread geometry and head design fared. I used a standard drill/driver with a clutch, a few drives with a compact impact driver, and a fresh T20 bit.

Design highlights that matter on site

- Type 17 tip: These are self-tapping points with a small cutting flute. In practice, that flute clears chips quickly enough to keep starts straight and reduce “walking” on the slick cap layer of composite boards.

- Dual-thread shank: Fine threads near the head and coarser threads lower on the shank are intended to pull the board and framing together without jacking the material. That split-thread profile also helps cut through fibrous composite without tearing.

- Diminishing head with reversing threads: A 10-degree taper under the head, paired with reverse threads, is meant to shave material as the head seats, minimizing mushrooming.

- T20 Torx drive: The T20 socket is a sweet spot—small enough for a relatively discrete head (0.266-inch diameter, 0.133-inch head height), but large enough to keep bit engagement solid in tougher composites.

- Coating for exterior and ACQ: The exterior coating is rated for pressure-treated and ACQ contact, which is non-negotiable if you’re fastening into modern treated lumber.

The 1-3/4-inch length is a deliberate choice. It’s shorter than typical deck-to-joist screws, making it better suited to fascia, skirt, and railing trim where you’re driving through thinner material and don’t want to risk punching through blocking or creating a fastener shadow.

Installation experience

With a fresh T20 bit, driving was drama-free in most cases. The Type 17 points bit quickly, even on cold-morning starts when the composite surface is slick. On long, edge-to-edge runs of fascia, I set my clutch to medium and used a slow drill speed; the screws cut consistently and seated cleanly. I had virtually no cam-out, even on awkward angles along stairs.

Mushrooming—the perennial fascia headache—was well controlled. On warm cap-stock boards, the diminishing head and reversing threads shaved the surface neatly, leaving only a faint halo. On colder days and with denser PVC trim, I still saw occasional puckering. A light 3/8-inch countersink pass solved that every time. If you’re chasing a perfectly flush, plug-ready finish in PVC, pre-countersink is still the most predictable path.

The dual-thread geometry does clamp well. On test boards where I intentionally left a minor bow, these pulled the material snug to the framing without lifting the work off the face. I like that the fine thread near the head seems to lock the head down without spinning or crushing the composite.

One caution: length matters with this design. At 1-3/4 inches, these are ideal for fascia plus a solid bite into framing, but if your stack-up gets thicker (layered fascia, shim, plus board), you can run into a scenario where the reverse-thread zone engages before the coarse threads fully anchor. In those situations, the screw may hesitate to finish seating. If you’re at all close on length, choose a longer composite screw. With the right length, these run home and stay there.

Removal and adjustments

I always test how fasteners back out, because mistakes happen. Backing these out at low speed worked fine in most cases. That said, the reverse threads under the head can act like a lock in dense composite. If a screw doesn’t want to back out smoothly, pulsing the trigger with steady pressure usually frees it. As a preventative step, I found that waxing a few screws (plain paraffin) for end-grain and near-edge locations made both driving and removal smoother.

Splitting, pre-drilling, and edge distances

The Type 17 tip does a good job reducing the need for pre-drilling, but physics still applies. Near ends, in cold weather, or in brittle PVC, I pre-drill with a 1/8-inch pilot and touch the surface with a countersink. That completely eliminated splitting and gave the most consistent finish. On composite fascia, I stayed at least 1-1/2 inches from board ends and edges, and that spacing, paired with the screw’s point design, prevented cracking.

Finish and color match

The walnut color blends well with common dark-brown composite lines and disappears nicely on fascia. The small head doesn’t shout on the surface, and the shade is dark enough that even minor haloing looks intentional rather than messy. For projects where the fastener should visually recede without the extra step of plugging, these hit a nice balance.

Corrosion and compatibility

These are coated for exterior use and chemical compatibility with pressure-treated and ACQ lumber. I can’t replicate a multi-year corrosion test in one project, but after wet/dry cycles and a couple weeks of exposure, there’s no discoloration or coating flake. The coating also seemed slick enough to help driving in dense boards.

Ergonomics and bits

A T20 bit is standard fare and widely available. Keep a fresh bit on hand—these small heads reward solid engagement, and swapping a worn bit early prevents stripped sockets. I drove most of these with a drill/driver; a compact impact is fine but makes it easier to overdrive in softer PVC. If you go the impact route, set a lower speed and practice on a scrap to nail your finish.

Quantity and use cases

The one-pound box is about 130 screws, which is just right for a fascia run, stair skirts, or a short railing project. It’s also useful for repairs where buying a 350- or 1000-count deck screw kit doesn’t make sense. A small quirk: my box had printed inspirational text under the flap. It’s harmless, but I moved the screws into a belt-friendly container for the job.

Limitations and best practices

- Not a miracle self-countersinker. The head geometry minimizes mushrooming, but in cold, dense materials you’ll still want a light countersink if you’re picky about the finish.

- Length choice is critical. The 1-3/4-inch version excels at fascia and trim. Don’t use it where a deeper bite is needed; choose a longer composite screw for thicker stacks or deck-to-joist fastening.

- Backing out can be stubborn in some composites due to the reverse-thread region. Drive straight, avoid over-torquing, and wax a few screws for end-of-board locations if you expect adjustments.

Small tips that helped:

- Pre-drill near ends and in cold weather.

- Run at low speed, with a firm, square approach, and let the tip do the work.

- Use a clutch or set your impact to low; stop as soon as the head kisses the surface.

- Keep a new T20 bit in the pouch; swap at the first sign of wobble.

Who will appreciate these screws

If you’re installing composite or PVC fascia, railing trim, or skirt boards into pressure-treated framing and want a reliable face-fastened look without plugs, these are a solid choice. The color match is discrete, the threads hold tight, and the heads sit cleanly with minimal fuss. They’re also great for small or mid-size projects where a one-pound box makes budgeting and storage easy.

If your project is thicker material or structural deck-to-joist fastening, step up in length—or consider a dedicated decking screw with a cutter head if you demand a perfectly flush finish without any prep.

Recommendation

I recommend these walnut composite screws for fascia, skirt, and trim work on composite and PVC where you’re fastening into treated lumber and want a clean, low-profile face-fastened finish. They start easily, hold hard, and keep mushrooming in check. Choose the right length for your stack-up, pre-drill near ends, and keep the speed low; with those habits, they deliver consistently neat results. For heavy structural runs or plug-and-play countersinking in the densest materials, you may prefer a different screw style or a longer option, but for their intended use these perform reliably and make the finish look professional.

Project Ideas

Business

DIY Composite Mini-Kit Product Line

Package pre-cut composite parts with matching walnut-coated screws, a T20 driver bit, and simple instructions to sell small DIY kits (e.g., planter boxes, trays, shelves). Emphasize ease of assembly (no pre-drilling needed in most cases) and the professional finish afforded by the diminishing head and reversing threads. Market online, at farmer's markets, and through local hardware stores.

Rapid Deck Repair & Trim Service

Offer a mobile service specializing in small composite deck repairs and fascia/cap stock replacements. Use these exterior-coated, Type 17-tipped screws to replace worn trim quickly with minimal prep work. Position the business as fast, cost-effective repairs (one-day turnarounds) for homeowners who need targeted fixes without full deck contractors.

Weatherproof Outdoor Furniture Line

Design and build a small run of outdoor benches, side tables, and Adirondack chairs using composite materials fastened with these walnut screws for a cohesive look. Highlight durability, low maintenance, and a consistent finish (no mushrooming or splitting). Sell direct-to-consumer online and to boutique lodging/Airbnb operators seeking long-lasting outdoor furniture.

Workshops & Video Tutorials + Kit Upsell

Run hands-on weekend workshops (or a YouTube/TikTok series) teaching composite-project techniques—how to use Type 17 tip screws, when to pre-drill, and how to avoid mushrooming with diminishing heads and reversing threads. Monetize through class fees, sponsorships, affiliate links to the screws, and bundled take-home kits containing the exact screws and pre-cut materials used in class.

Creative

Miniature Deck Serving Tray

Build a compact serving tray that looks like a slice of a deck using composite cap stock strips. Use the walnut-color screws countersunk into the 10° diminishing heads for a flush, finished look. The Type 17 tip lets you start screws cleanly into the fibrous composite without pre-drilling, and the dual threads reduce splitting while the reversing threads minimize mushrooming—ideal for a polished, weatherproof indoor/outdoor tray.

Stacked Outdoor Planter Box with Composite Slats

Create a modular planter using composite decking slats for the sides and composite fascia for trim. The exterior-coated screws resist corrosion in wet soil conditions; T20 Torx drive speeds assembly and the dual fine/coarse threads bite through composite cleanly. Design the planters to stack or interlock for balcony-friendly urban gardens.

Floating Wall Shelf with Composite Accent

Make durable, moisture-resistant floating shelves by fastening composite fascia to a hidden steel or hardwood bracket. The screws' diminishing head and reversing threads keep the surface smooth and free of mushroomed fibers, while the walnut color gives a cohesive, upscale look when the shelf face is composite.

Poolside Towel Ladder / Railing Rack

Construct a compact towel ladder or rack using composite railing pieces and cap stock for rungs. The screws are optimized for composite-to-pressure-treated connections, so they hold snugly in outdoor, humid environments. The Type 17 tip reduces walking while starting, letting you assemble a sturdy, rust-resistant rack quickly.