Features

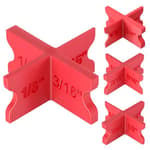

- Dimensions: Screw Diameter .195" - Head Width 0.266" - Head Height .133" Use T20 Torx/Star Diver Bit

- 10 Degree Diminishing Head and Reversing Threads to Prevent Mushrooming

- Dual Threaded (fine/coarse) Assists With Cutting Through Fibrous Decking Material

- Type 17 Tip for Fast Starts, Helps Eliminate "Walking" and Easier Installation without Pre-Drilling

- Uses Include Cap Stock, PVC and Composite Decking, Composite Fascia and Composite Railing

Specifications

| Color | MOCHA (COCOA BROWN) |

| Size | MOCHA 5 POUNDS ~655 Screws |

| Unit Count | 655 |

Related Tools

These 1-3/4" exterior-coated composite decking screws in mocha (approx. 655 screws, 5 lb) are for fastening composite, PVC, cap stock, fascia and railing to pressure-treated and ACQ lumber. They have a 10° diminishing head with reversing threads to reduce mushrooming, dual fine/coarse threads for cutting through fibrous decking, a Type 17 tip for fast starts, and are driven with a T20 Torx/Star bit.

Jake Sales 10 x 1-3/4" Mocha Composite Decking Screws. Exterior Coated, Pressure Treated and ACQ Lumber Compatible. Use T20 Torx/Star Dive Bit Review

I spent a weekend wrapping a composite deck in fascia and stair risers, and I used the Jake Sales mocha composite screws for the entire job. They’re the 1-3/4" version—the sweet spot for 1/2" to 3/4" fascia into pressure-treated framing—and they’re color-matched in a cocoa-brown that blends well with most mocha/caramel boards. After driving a few hundred of them through capped composite and into ACQ lumber, here’s how they performed.

Design that’s purpose-built for composites

These screws aren’t just painted deck screws. The details matter:

- The T20 Torx/Star drive resists cam-out and lets you keep steady downward pressure without stripping the head.

- A Type 17 auger tip starts quickly and helps prevent “walking,” which is useful on slick, capped surfaces.

- Dual threads—coarse below, fine near the head—are tuned for dense, fibrous decking. The reverse (fine) threads under the head help reduce mushrooming by pulling the material up as the head seats.

- A small, diminishing head (.266" wide, .133" tall) hides neatly in brown composites and trim.

The exterior coating is marketed as compatible with pressure-treated and ACQ lumber. I sunk many of these into wet PT framing; the coating didn’t flake under normal driving and I saw no red rust after rain exposure during the build. Time tells the full story on corrosion, but the finish seems robust.

Driving and seating

I drove the screws with both a compact impact driver (low power mode) and a 12V drill/driver using a clutch. The T20 recess fit snugly on a quality bit and stayed crisp—no skating or early wear after a few hundred screws. The Type 17 tip consistently bit into composite without predrilling, even at slight angles.

Seating is where composite screws earn their keep or show their limits. The reversing threads below the head do a respectable job of minimizing the “mushroom” lip you often see when a standard deck screw compresses the composite skin. On flat field locations, I got a clean seat most of the time. Near board ends or on cooler mornings when the material was less pliable, I occasionally saw a slight halo around the head. A light countersink pass made that go away. More on that in the tips section.

One note on technique: run them in at moderate speed and feather the trigger as the head nears the surface. Hammering them home at full RPM with an impact driver increases the chance of a raised ring around the head.

Length matters with these threads

At 1-3/4", this model is ideal for fascia and trim into framing, not for top-down decking. With 1/2" fascia, you still get ample bite into the joist, and the reverse threads can do their mushroom-mitigating work without starving the main threads of embedment. Try to use this length for 1" deck boards and you’re asking the reverse threads to seat the head while the main thread doesn’t have enough wood to hold; that can make the screw stall shy of fully flush. If you’re fastening deck boards through the face, go longer—2-1/2" or 2-3/4" depending on thickness—and you’ll avoid that bind.

Removal and “oops” adjustments

Composite fascia installs often involve minor alignment tweaks. Backing these screws out is generally fine if they’ve fully seated. If a screw stalls midway (common when the length is marginal or the material is dense), the reversing threads can lock the head in place while the main thread hasn’t cleared, making removal stubborn. My workaround: rock the driver to relieve head pressure, pulse the trigger in reverse, and if needed, step-drill 1/8" just through the fascia skin to free the reverse thread. Lubricating the first few threads with a little paste wax also helps on trouble spots.

Finish and color

The mocha head coating is a close match to many brown composites. In direct sun the tone reads more cocoa than espresso—subtle enough that once seated, the fasteners visually disappear at normal viewing distance. I drove and backed out a handful to test chipping; no significant flake-off. If you’re super particular about color, test on a scrap first—brown composites vary widely between brands.

Mushrooming performance

No composite screw completely eliminates mushrooming in every board, every temperature, every location. These reduce it meaningfully. On my fascia (capped composite, mid-70s Fahrenheit), most heads sat clean with no raised lip. On stair risers (thicker and stiffer), I occasionally needed a quick countersink. If you expect a completely flush, plug-free finish on a proud fascia line, plan to keep a countersink bit handy. The screws don’t create a neat conical pocket the way a true self-countersinking head with cutting nibs would.

Compatibility with PT and ACQ

The exterior coating claims compatibility with treated lumber, and that squares with my experience. The screws cut into wet PT without squeal or galling, and after a couple of rainy days mid-project I didn’t see any discoloration around the fasteners. If you’re in a coastal environment or prioritizing maximum longevity, stainless trim-head screws still have an edge, but you’ll give up the color match and mushroom control.

Packaging and quantity

A 5-pound box is roughly 650+ screws—more than enough for a typical fascia and stair project with leftovers for rail components or future repairs. There’s no T20 bit in the box, so have a few on hand. Minor note: my carton had an inspirational message printed under the flap. It doesn’t affect performance, but if you’re tossing the box into a shared jobsite bin, know it’s there.

Tips for best results

- Choose the right length. Use these 1-3/4" screws for 1/2"–3/4" fascia and trim into framing; use longer screws for deck boards.

- Set your driver to low speed. Feather the trigger as the head seats to minimize halos.

- Pre-countersink near ends. A quick kiss with a countersink at board ends or in colder temps yields a cleaner finish.

- Wax tricky starts. A dab of paste wax on the first threads helps in dense or cold material and makes removal easier if needed.

- Use a clutch or impact on low power. Overdriving can crater the composite skin.

- Keep spare T20 bits. A snug, unworn bit dramatically reduces cam-out.

What I liked

- Solid drive engagement with T20 and a tough recess; no cam-out and minimal bit wear

- Reverse threads that noticeably reduce mushrooming in most situations

- Type 17 tip that starts cleanly without predrill in the field

- Durable mocha coating that blends well with brown composites and resists chipping

- ACQ-compatible coating holding up well in early exposure

Where they come up short

- Not a universal self-countersink; some boards and conditions still benefit from a light countersink

- Removal can be stubborn if a screw stalls before fully seating

- The 1-3/4" length is great for fascia but not ideal for top-down decking: choose longer for that

Bottom line

For fascia, risers, and composite trim into treated framing, these Jake Sales mocha composite screws do what they claim: they start cleanly, hold tight, and keep mushrooming in check with a finish that blends into brown boards. They’re not magic—edges and cold boards may still need a touch of countersink—and they reward you for choosing the right length for the job. But with sensible technique, they deliver a neat, durable installation.

Recommendation: I recommend these for composite fascia, risers, and railing components where color match and reduced mushrooming matter. They’re dependable with a good drive feel, the coating plays nicely with ACQ, and the 1-3/4" length is well-suited to trim applications. If you’re fastening deck boards through the face or you anticipate frequent removal and rework, pick a longer version or consider a screw with more aggressive self-countersinking. Otherwise, these are a strong, workmanlike choice for brown composite trim work.

Project Ideas

Business

Composite Deck Installation Service

Start a specialty deck installation business focused on composite/PVC materials. Market the use of purpose-made fasteners (T20-driven, Type 17 tip, reversing threads) to reduce splitting/mushrooming and speed installs—offer warranties and routine maintenance contracts.

DIY Deck Repair Kits

Package consumer-friendly kits containing mocha composite screws, a T20 Torx bit, simple jigs/templates, and step-by-step repair guides (video + print). Sell kits online or in home-improvement stores for homeowners fixing loose boards or replacing fascia.

Contractor Bulk Supply & Subscription

Offer bulk 5 lb packs and a subscription service for contractors and property managers who need regular lead times. Provide volume pricing, fast-shipping options, and specification sheets showing ACQ compatibility and application types.

Hands-On Workshops & Monetized Content

Run paid local workshops or online courses teaching best practices for composite deck fastening, pattern design, and furniture from composite scrap. Monetize via ticket sales, affiliate links to the screw packs and T20 bits, and premium downloadable plans.

Upcycled Composite Furniture Line

Produce a small line of upcycled furniture and décor from leftover composite offcuts fastened with mocha screws. Sell direct-to-consumer via Etsy/Shopify or to local boutiques; emphasize durability, low-maintenance materials, and the professional fastener finish.

Creative

Mocha Deck Mosaic

Use the mocha screw heads as a visible dot grid to create geometric or pictorial mosaics across composite deck boards. Lay out patterns with a template, drive the T20 Torx screws flush for uniform dots (reversing threads help avoid mushrooming) and seal the deck for a clean, weatherproof finish.

Hidden-Fastener Composite Planters

Build modern outdoor planters from composite boards using the Type 17 tip screws for fast starts without pre-drilling. Countersink and conceal some fasteners or position visible mocha heads where they complement the design for a refined, maintenance-friendly planter.

Weatherproof Bench & Table Set

Construct a compact outdoor bench and coffee table from composite decking and fascia. Use the dual fine/coarse threads to get strong hold in fibrous composite and ACQ-treated framing; the mocha finish gives a coordinated, professional look.

Privacy Screen with Integrated LED Inlay

Assemble a slatted composite privacy screen using the screws to attach cap stock and railing pieces. Space fasteners deliberately as part of the aesthetic, then route channels behind the slats for LED strips—mocha screws blend with warm finishes for a subtle, finished appearance.

Decorative Railing Accents

Design a custom railing where exposed mocha screw heads form decorative lines or accents along caps and balusters. The 10° diminishing head and reversing threads reduce mushrooming for a consistent, high-end visible finish.