Features

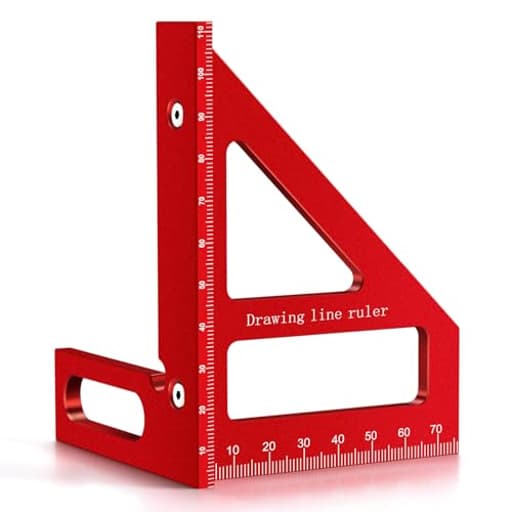

- 【High-quality】Our multi-angle measuring ruler is crafted from premium aluminum alloy. The surface of the triangle ruler undergoes anodization treatment, which endows it with excellent corrosion resistance and a smooth finish, guaranteeing user safety and long-term durability.

- 【Accurate and Clear Markings】The high-precision layout measuring tool is equipped with laser-printed scale lines, ensuring both precision and durability. These markings are not only clear and easy to read but also enable accurate measurement, thus enhancing working efficiency.

- 【Multiple Used】The multi-angle ruler serves multiple purposes. Functioning as a woodworking measuring tool, square, and protractor, it excels in tasks like measuring, correcting, and marking lines. Notably, it is highly suitable for round materials, three-dimensional workpieces, square wood, and pipes.

- 【Applicable Scenario】Ideal for home use by DIY enthusiasts, Our multi-angle measuring ruler is also an indispensable aid for carpenters, engineers, and decoration workers in their professional tasks. And it makes a thoughtful, practical best gift for DIY lovers.

- 【What You Get】1x multi-angle measuring ruler, 1x Small Wrench, and 3x Screws. Among them, one screw serves as a spare. Please feel free to contact us if you have any problem with the product.

Specifications

| Color | Red |

| Unit Count | 1 |

Related Tools

Related Articles

A multi-angle measuring ruler that functions as a 45°/90° square, protractor and miter triangle for measuring, marking, and checking angles on wood, pipes, round and three-dimensional workpieces. The anodized aluminum alloy body has laser-printed scale lines for durable, easy-to-read measurements; the package includes a small wrench and three screws (one spare).

Jimtoiny 3D Multi-Angle Measuring Ruler, Professional 45 90 Degree Aluminum Alloy Woodworking Square Protractor, Miter Triangle Ruler, Precision Layout Measuring Tool Metric Construction Rulers Review

First impressions

A palm‑sized square can punch well above its weight in a shop. After a few weeks with the Jimtoiny multi‑angle square, it’s become one of those little fixtures that migrates from the bench to my apron pocket and back again. It’s not a framing square or a precision machinist tool—and it doesn’t pretend to be—but for quick layout, transferring marks around edges, and checking 45°/90° cuts on smaller stock, it’s surprisingly capable.

What’s in the box and how it goes together

The tool arrives as two aluminum pieces that assemble with two small screws using the included hex wrench; a third screw in the kit is a spare. I like this modular approach more than I expected. Disassembled, the parts tuck neatly into a compact case and slot easily into a toolbox. Assembled, you get a rigid right‑angle body with a 45° reference, ready for layout work.

Assembly is straightforward: align the holes, snug the screws, and you’re done. If you plan to keep it assembled long‑term, a dab of medium‑strength threadlocker keeps the screws from drifting loose over time. If you’ll be breaking it down frequently, finger‑tight plus a quarter turn with the wrench was enough to keep mine solid during use.

Build quality and markings

The aluminum is anodized, edges are cleanly machined, and there’s a small relief at the inner corner that prevents the sharp inside point from bruising your work or trapping dust. That relief also lets you register around a slightly rounded corner or a dowel without the tool rocking, which I appreciate when working with eased‑edge plywood and dimensional lumber.

The scales are laser‑marked in metric (mm/cm) only. The markings are crisp, high‑contrast, and easy to read under shop lighting. I haven’t seen any fading or chipping through normal use, but as with all laser markings on anodized aluminum, I’d avoid abrasive cleaners or scrubbing the faces against masonry. If you work exclusively in imperial, the metric‑only scales may be a deal‑breaker. For me, the scale is most useful for quick offsets and spacing; when I need exact inch measurements, I grab a tape or combination square.

Size, feel, and ergonomics

This is a compact tool—more “apron pocket” than “framing pouch.” On 1x stock, trim, furniture parts, and smaller panels, the size is an asset. It’s excellent for transferring a face mark around to an edge or end, squaring lines across narrow workpieces, and confirming a 90° edge out of the saw. On thicker stock (4x4s, beefy timbers), the short legs mean less bearing surface; it still works as a reference, but it’s not the right choice if you need long registration on big work.

As a square, it feels stable in hand, especially when you bear your thumb into the inside corner relief. As a 45° reference, it’s quick to set lines for miters, face frames, or bevel checks. Rounded over edges on the tool keep it from chewing up softer woods if you’re sliding it along while scribing.

Accuracy and how I used it

I checked the 90° against a reference square and the 45° against a miter gauge; both were true to within normal woodworking tolerances. This is the sort of accuracy I expect from a well‑made aluminum square—plenty for layout and checking without chasing thousandths.

Some daily uses it handled well:

- Transferring knife marks from a board face to its edge to ensure dead‑accurate crosscuts.

- Scribing a cut line around a dowel and small copper pipe by rotating the tool as a guide, then confirming square.

- Quickly verifying that a cabinet side off the track saw was truly 90° before assembly.

- Laying out 45° miters on trim pieces without hauling out a larger speed square.

Because the body is slim, it’s also handy for getting into tighter corners where a bulky speed square won’t fit, like inside a carcass or drawer.

Working with round and three‑dimensional parts

While it’s not a dedicated pipe gauge, the flat faces register well enough against round stock to make consistent marks. For dowels and small pipe, I used a light touch and rotated the work rather than the tool to keep lines square. It’s also useful on three‑dimensional workpieces where you need to trace a line from one face to another without losing your reference. That inside corner relief again helps keep the tool from teetering on eased edges.

Storage and shop workflow

When assembled, it’s a bit awkward to toss in a shallow drawer without snagging other items. Hanging it on a pegboard or keeping it in the included case solves that. I eventually added a small cord loop through one of the holes so I could hang it on a French cleat hook near the bench—easy to grab, harder to misplace. If you expect to assemble and disassemble it constantly, consider dedicating a spot for the screws and wrench so they don’t go wandering.

Durability and long‑term considerations

The anodized finish has held up well to bench life so far. The edges remain true, and the faces haven’t picked up burrs from normal scribing with a pencil or knife. As with any small tool that relies on screws for rigidity, repeated assembly cycles could wear the threads if you over‑torque them; snug is enough. I’d also avoid dragging the marked faces across abrasive surfaces to protect the laser markings over the long haul.

One nitpick: because the tool is compact, there’s not much surface area to grip when you’re squaring against thicker, rougher stock. A bit of painter’s tape on the tool face can add friction temporarily without marring the finish.

Where it shines—and where it doesn’t

Shines:

- Fast, reliable 90° and 45° layout on small to medium stock.

- Transferring marks across edges and around corners.

- Pocket‑friendly accuracy checks during assembly.

- Working inside boxes, drawers, and tight spaces.

- Quick scribing on dowels and small pipe.

Doesn’t:

- Large framing or site work where longer registration is essential.

- Users who require imperial scales on the tool.

- Heavy machine work or tasks that demand adjustable fences and long rulers.

How it fits with other layout tools

This doesn’t replace a speed square, combination square, or framing square; it complements them. I still reach for a 12‑inch combination square for adjustable depth and imperial measurements, and a speed square for large sheet goods. But the Jimtoiny’s small footprint makes it the one I grab for fast checks and layout on smaller parts, especially when building boxes, frames, and shop jigs. It also doubles as two right‑angle references if you use the pieces separately, which I’ve done to keep parts square during glue‑ups.

Tips for best results

- Keep a mechanical pencil or marking knife handy; the crisp edges reward sharp layout tools.

- Snug the screws—don’t over‑tighten—to preserve the threads and keep the faces flush.

- If you’re going to keep it assembled, add a drop of medium threadlocker and hang it near your bench.

- Protect the faces from abrasive grit to keep the laser markings legible over time.

- If you work in imperial, set a metric‑imperial conversion chart at the bench or use it primarily as a square and reference, not a measuring stick.

Value

For a budget‑friendly, anodized aluminum square with laser markings, the value is solid. You’re paying for portability, quick references, and a stable 45°/90° in a compact form. If you need a primary layout tool for bigger jobs or insist on imperial units, your money is better spent elsewhere. As a secondary square that stays close at hand, it’s easy to justify.

Recommendation

I recommend the Jimtoiny multi‑angle square as a compact, well‑made helper for small‑to‑medium woodworking tasks, jig building, and quick checks during assembly. Its strengths are portability, clear metric markings, reliable 45°/90° references, and the flexibility to break down for storage or use the pieces independently. Its limitations—metric‑only scales, small size, and screw‑based assembly—make it a poor fit for large carpentry, imperial‑only workflows, or heavy abuse. If you work mostly at the bench and appreciate a pocketable square that speeds up layout without getting in the way, this one earns a spot in the shop.

Project Ideas

Business

Custom Frame & Trim Shop

Start a small shop offering custom picture frames, mirror frames and interior trim work emphasizing precision miters and unusual angles (bay windows, odd corners). Market the shop to art collectors, interior designers and homeowners wanting professional-looking bespoke trim—use the multi-angle ruler as a selling point for accuracy and complex-angle capability.

On-Site Measurement & Fix Service

Offer a mobile service for cabinet installs, door/frame adjustments, and built-in furniture where precise angle measurement matters. Advertise quick on-site angle verification, re-cutting of trim, and tailored shimming. Use the tool to troubleshoot problematic miter joints and irregular walls; charge for diagnostics plus labor or offer packaged hourly rates.

Tutorials, Plans & Digital Templates

Create and sell digital project plans, angle-marking templates, and step-by-step tutorials that show how to use the multi-angle ruler to build specific items (frames, tables, lamps). Bundle printable templates with video walkthroughs demonstrating layout, marking and angle checks. Sell via an Etsy shop, Gumroad, or your own website and include affiliate links to buy the ruler.

Content Channel with Tool-Focused Demos

Build a YouTube/TikTok/Instagram channel focused on precision layout and angle techniques for makers. Produce short clips showing clever uses of the ruler (e.g., transferring angles from walls, laying out compound miters on trim, working with round stock). Monetize through ads, sponsorships from tool brands, Patreon for exclusive plans, and selling branded templates or starter kits.

Product Bundle & Private-Label Kits

Source the multi-angle ruler and assemble value-added kits: ruler + small square + digital course, or ruler + jigs and pre-cut lumber for popular projects (e.g., floating shelf kit, DIY frame kit). Private-label the ruler with your brand, bundle with instructions and sell on marketplaces. Offer wholesale pricing to woodworking classes, makerspaces and gift retailers.

Creative

Geometric Triangle Wall Panels

Use the multi-angle ruler to mark and cut dozens of precise 45° and 90° triangular panels from plywood or hardwood. Assemble into a modular geometric mosaic (repeating triangles, chevrons, or star patterns) and finish with stain or contrasting paint. The ruler’s protractor function helps you vary angles for more complex tessellations and ensures repeatable accuracy for a clean, professional look.

Perfect-Miter Picture & Mirror Frames

Leverage the ruler’s miter-triangle and square features to lay out and check 45° miters for picture frames, shadow boxes or decorative mirror mouldings. Use the laser scales to measure rabbet depths and verify corner squareness before gluing/clamping. Offer customization like inlay strips, routed profiles, or painted patterns for a premium handcrafted frame line.

Angled-Leg Stool or Side Table

Design a small stool or side table where all legs splay at consistent angles. Use the tool to mark leg shoulders, transfer angles to mortises or pocket holes, and verify the table top’s squareness after assembly. The ruler’s ability to work on round and three-dimensional pieces makes it ideal for tapered or turned legs and irregular tabletops.

Pipe & Tube Lamp with Precision Joints

Create industrial-style lamps from metal pipe/tube where each joint must meet at precise angles. The ruler helps set and check angles on round components, mark cut lines for butt/joined fittings, and lays out decorative bracket shapes. Combine with wood bases or metal shades cut and mitered using the ruler for polished artisan lighting.

3D Papier-Mâché or Leather Pattern Drafting

Use the protractor and angle-checking features to draft flat patterns for three-dimensional projects: leather bags with angular gussets, papier-mâché faceted sculptures, or fabric panels for geometric lampshades. The ruler assists in plotting seam lines and angle transitions so patterns fold and assemble cleanly into accurate 3D forms.