Features

- Clamping force up to 1,000 lb (≈450 kg)

- 15 ft (4.5 m) nylon band

- Removable corner guides for irregular shapes

- Ergonomic quad-lobe bi-material (soft-grip) handle

- Suitable for round, square, or irregular projects

- Includes one clamp

Specifications

| Average Clamping Force (Kg) | 450 |

| Clamping Force (Kg) | 450 |

| Maximum / Sustained Clamping Force (Kg) | 450 |

| Band / Bar Length | 4500 mm (15 ft / 4.5 m) |

| Band Material | Nylon |

| Body Material | Plastic |

| Clamping Capacity (Mm) | 4230 |

| Maximum Jaw Opening (Mm) | 4270 |

| Jaw Depth (Mm) | 30 |

| Jaw Width (Mm) | 25 |

| Handle Material | Soft grip (bi-material) |

| Handle Type | Quad-Lobe |

| Number Of Pieces | 1 |

| Packaging | Blister |

| Product Dimensions With Packaging (L × W × H) | 390 mm × 190 mm × 40 mm |

| Product Length (Mm) | 390 |

| Product Width (Mm) | 190 |

| Product Height (Mm) | 40 |

| Product Weight (Kg) | 0.6 |

| Product Weight (Lbs) | 1.2 |

| Product Weight (G) | 600 |

| Maximum Opening (Reported Elsewhere) | 180 in |

| Included Items | (1) clamp |

| Warranty | Limited warranty (see manufacturer for terms) |

Related Tools

Related Articles

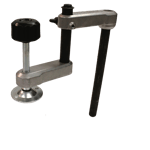

A band clamp with a 15 ft (4.5 m) nylon strap intended for clamping irregular, round, or square objects. It provides up to approximately 1,000 lb (≈450 kg) of clamping force, uses removable corner guides to position corners, and has a quad-lobe soft-grip handle to tension the band. The main body is plastic. Includes one clamp.

DeWalt 15 ft. (4.5 m) Nylon Band Clamp Review

A band clamp that’s handy, if you learn its quirks

I reached for the DeWalt band clamp to handle a few glue-ups that ordinary bar clamps don’t love: a square picture frame, a hexagonal planter, and a small round table apron. The 15-foot nylon strap, removable corner guides, and a twist handle that tensions from both sides make this a flexible problem-solver. After several sessions with it, I’d call it a useful shop companion with a learning curve—and a few durability and usability caveats you should know.

Setup and ergonomics

Out of the blister pack, the clamp is light at roughly 1.2 lb, with a plastic main body and a bi-material quad‑lobe handle. The handle shape is excellent; it’s easy to grip with dry or gluey hands, and you can generate real torque without hot spots. The two cam locks on either side of the body control band length and keep the strap from back-feeding while you tension. The removable corner guides slide along the strap and help distribute pressure at corners or around irregular shapes.

A couple of setup notes improved my experience:

- Pull 8–12 inches of slack on the short strap end before you start. It makes threading corners and pre-positioning easier.

- Lay the strap perfectly flat around the work and seat the corner guides fully. Any twist compounds as you tension.

- Keep a small pair of Velcro cable ties on the strap for quick, tidy management of the 15-foot tail.

The unlock levers for the cams sit close to the body. They’re secure (they don’t pop open), but they require a deliberate press to release and can be a little stiff until you get used to the motion. I prefer that to a loose cam that slips mid-glue-up.

Clamping performance

DeWalt lists up to about 1,000 lb of clamping force. In practice, the useful range depends on how well you seat the strap in the cams and how clean everything is. On the picture frame, I was able to draw joints tight evenly, check diagonals, and add a bit more twist without any drift or noticeable strap stretch. For the hex planter and the round apron, tightening from both sides helped prevent skewing—a real advantage over ratcheting web clamps that pull to one side.

Where the system starts to show its limits is near the top end of tension. On a stubborn mitered box where I purposely left the joints a whisker proud to test it, I could feel the plastic body flex slightly as I muscled the handle. More importantly, I saw the short strap end try to creep in the cam once I hit “too tight.” Backing off a quarter turn stopped the creep and held fine through cure. I’d call the clamp’s sweet spot “light to medium-high” tension—plenty for most wood glue-ups, veneers, edge banding, and assemblies where even compression is the goal. If you routinely push clamps to the absolute max, a metal-bodied ratcheting band clamp or traditional bar clamps will be more confidence-inspiring.

Strap and corner management

The 15-foot nylon strap is the right call for range; I wrapped a small 8-inch frame and a 30-inch round with room to spare, and the reported 180-inch maximum opening is believable with the corners off. Nylon doesn’t mark the work and doesn’t pick up glue too badly if you wipe it off early.

Two nits:

- The strap ends are heat-finished, but the factory adhesive at the very tips of mine did little. After a few uses, I stitched a simple bar tack 1 inch from the end on the short side as a keeper. That completely eliminated any creep and made re-threading easier if the strap ever pulled free.

- The corner guides are helpful and smooth, but they can slip off if you fully slack the strap while moving between workpieces. A piece of blue tape or a small binder clip keeps them captive when you don’t want them wandering.

For storage, the tool offers no built-in strap wrap. I loop the strap and secure it with two Velcro ties. A zippered pouch or shoe bag is a neat, low-tech solution that prevents tangles and protects the plastic body in a drawer.

Build quality and durability

The body is plastic, and that’s both a strength and a limitation. It keeps the weight down, the handle is comfortable, and it won’t ding a finished corner if you bump the work. But plastic doesn’t love abuse. If you crank hard as if it were a ratcheting web strap for cargo, you’ll flex the housing and risk damage. Use it as a precision clamping tool, not a tie-down, and it holds up. My cams engage positively and the teeth remain crisp; I rinsed dried glue out with warm water and a toothbrush to keep them biting cleanly.

I’ll also call out the strap anchoring again: if you notice the short tail creeping under high tension, stitch or tie a small keeper so you can lean on the handle without worrying. It’s a simple DIY fix that improves long-term reliability.

Capacity and real-world uses

- Length: 15 ft (4.5 m)

- Effective clamping capacity: around 4.2 m depending on setup

- Strap: nylon

- Body: plastic

- Weight: ~1.2 lb (0.6 kg)

- Handle: quad-lobe soft grip, twists to tension

Where it shines:

- Picture frames, shadow boxes, cabinet doors

- Multi-sided assemblies (hex/octagon planters, stool bases)

- Round workpieces (drum shells, hoops, table aprons)

- Glue-ons like edging where you want wraparound pressure

- Clamping irregular shapes using the corner guides as pressure spreaders

I had good success using the corner guides as floating pads on the round apron; they kept the strap from sliding down the curve. For a live-edge tray with a slightly irregular perimeter, I popped off one or two corners entirely and let the strap bear directly on the edge with a scrap caul—versatile.

Tips for best results

- Prep the strap: keep it clean and flat; a quick wipe prevents glue crust that can make the cams slip.

- Pre-tension evenly: snug the strap by hand, lock both cams, then twist the handle in small increments while checking for square or concentricity.

- Use cauls: especially on fragile veneers or sharp corners. The corner guides help, but a thin scrap between the strap and the work spreads pressure further.

- Mind the tail: keep it managed; loose tails find wet glue.

- Don’t overdrive: if the body flexes or the short tail creeps, you’re past the tool’s comfort zone—back off slightly.

Comparisons and alternatives

Compared to metal-framed ratcheting web clamps, this design is lighter and tightens from both sides, which keeps assemblies centered. Ratchet straps can achieve higher peak tension and feel more bombproof, but they pull off-axis and can twist frames if you’re not careful.

Versus pipe or parallel clamps, a band clamp wins whenever the shape isn’t straight or when you need equal wraparound pressure. It won’t replace bar clamps for edge gluing boards or for pulling joinery into submission, but it complements them nicely.

If you anticipate daily use on heavy assemblies, a band clamp with a metal tensioning body and a wider strap might be worth the upgrade. If you want portability and a comfortable handle for occasional frames and odd shapes, this DeWalt is right in the pocket.

The bottom line

The DeWalt band clamp is versatile, lightweight, and genuinely helpful for shapes that frustrate bar clamps. The handle is comfortable and the dual-sided tensioning keeps projects centered. Its limitations show up at the extreme end of torque, where the plastic body can flex and the short strap end may creep if not managed. The corner guides are useful but easy to misplace, and there’s no built-in strap storage.

Recommendation: I recommend it for light to medium‑high clamping tasks—picture frames, multi-sided glue-ups, and round or irregular projects—especially if you value even pressure and quick setup. Add two small upgrades (a stitched keeper on the short strap end and a pair of Velcro ties for storage), learn the cam behavior, and you’ll get reliable results. If your work regularly demands maximum clamping force or you’re rough on tools, consider a metal-bodied band clamp or traditional bar clamps instead.

Project Ideas

Business

On-Site Frame Assembly Service

Offer mobile picture/mirror frame assembly for interior designers and galleries. Use the band clamp to square and glue large or irregular frames on location, reducing transport risk. Sell upgraded finishes, glass, and hanging hardware as add-ons.

Chair and Furniture Re-Glue Clinic

Specialize in tightening loose chairs and wobbly joints. The strap clamp conforms to odd angles and curved parts that bar clamps can’t reach. Offer flat-rate repair per joint, with premium for antique-safe methods and in-home service.

Custom Hex/Octagon Planter Production

Batch-produce premium cedar or hardwood planters in geometric shapes. The band clamp speeds multi-side glue-ups and keeps edges flush. Sell through local nurseries and online; offer personalization and weatherproof finishes.

Rental + Workshop Kit for Makerspaces

Create a clamp rental bundle with band clamps, corner guides, protective cauls, and quick instruction cards. Partner with makerspaces and community shops to rent for frame-ups, segmented bowls, and lamination projects. Upsell consumables like glue and sandpaper.

Content + Affiliate Channel: Clamp Hacks

Build a niche video/blog channel demonstrating strap clamp techniques: miter alignment tricks, bent lamination workflows, complex polygon glue-ups, and repair hacks. Monetize through affiliate links, digital plans, and sponsored tool reviews.

Creative

Segmented Wood Bowl Glue-Up

Use the band clamp to evenly compress segmented rings for a turned wood bowl. The 15 ft nylon strap wraps multiple rings at once, and removable corner guides act as spacers between segments to prevent slippage. The soft-grip handle lets you dial in even pressure up to 1,000 lb for gap-free joints before the bowl blank heads to the lathe.

Hexagonal/Octagonal Planter Boxes

Cut miters for a hex or octagon planter, dry fit, then wrap with the band clamp to pull all corners tight at once. The corner guides keep edges aligned while you tension. The long strap accommodates tall planters; add an inner caul to keep sides square. Great for cedar, composite, or reclaimed boards.

Bent Lamination Side Table Rim

Form thin strips of wood around a round form to create a circular rim or tray lip. The nylon strap distributes pressure around the curve without marring, and the extended length allows multiple wraps for stronger, uniform clamping. Ideal for a modern side table or serving tray with continuous grain.

Large Picture/Mirror Frames

Assemble oversized frames that exceed typical bar clamp reach. Use the corner guides as reference blocks to keep miters true while the band pulls all corners simultaneously. Add cauls under the band to protect delicate moldings. Perfect for gallery frames and mirrors up to door size.

Drum or Hoop Instrument Build

Glue up a stave drum shell or laminate hoops for a banjo/hand drum. The strap’s high clamping force makes tight, round glue lines, and it conforms to irregular stave profiles. Place waxed paper under the band to avoid glue squeeze-out sticking to nylon.