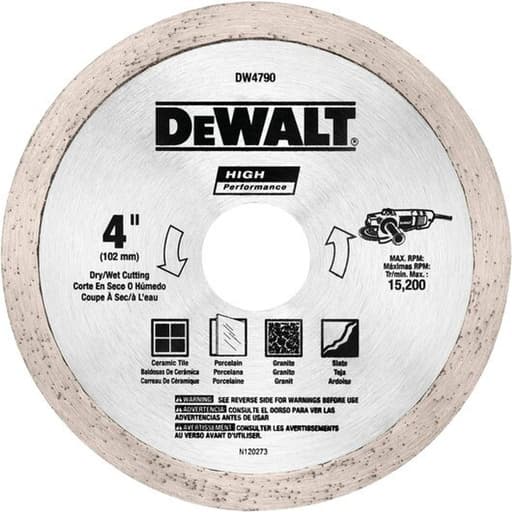

Features

- Diamond matrix intended for extended life and reduced chipping

- Suitable for wet or dry cutting

- Thin kerf to reduce dust and increase cutting speed

- Designed for tile and stone

Specifications

| Diameter | 4 in |

| Thickness | 0.06 in (1/16 in) |

| Arbor | 5/8-11 |

| Cutting Mode | Wet or dry |

| Material | Diamond matrix |

| Intended Materials | Tile and stone |

| Kerf | Thin (0.06 in) |

Related Tools

Related Articles

Tile blade designed for wet or dry cutting of tile and stone. It uses a diamond matrix aimed at extended life and reduced chipping. The blade has a thin kerf to reduce material removal and limit dust generation during cutting.

DeWalt HP Tile Blade Review

A thin-kerf diamond blade on a grinder can make or break a tile day. I put this DeWalt tile blade to work across a couple of real jobs—porcelain floor tile, some ceramic wall pieces, and a handful of natural stone cuts—using both dry and water-assisted passes. It’s a compact 4-inch blade with a 1/16-inch kerf and a diamond matrix that’s aimed squarely at fast, clean cuts without a lot of dust or drama. Here’s how it actually behaved in the field.

Setup and compatibility

Arbor and fit: This blade uses a 5/8-11 threaded arbor, which means it threads directly onto most U.S. angle grinders without relying on flanges. That’s convenient for quick swaps and it feels secure in use. It’s not the right arbor for many tabletop wet tile saws, which typically use a smooth 5/8-inch bore with clamping flanges. If your plan is to run this on a bench-top wet saw, check compatibility first—you’ll likely want the non-threaded version of a similar blade.

Diameter and depth: At 4 inches, maximum cutting depth is limited (on a typical 4-1/2-inch grinder, you’ll get roughly an inch of cut at full plunge). That’s fine for most wall and floor tiles and stone thresholds, but not ideal for thicker pavers or miters where a larger blade would be useful.

Safety pairing: Dry cutting creates silica dust. I ran a shrouded grinder connected to a HEPA vac for interior work and a respirator outdoors. For wet cuts, I used a simple spray bottle to mist the kerf, which dramatically reduced dust and edge chipping.

Cutting performance on tile

Ceramic: On glazed ceramic, this blade tracks true and produces a clean edge with minimal micro-chipping. Straight rips are quick with a light feed. On outlet cutouts and L-cuts, the thin kerf helps keep corners crisp, especially if you score once and then finish with short, shallow connecting passes.

Porcelain: Porcelain is always a tougher test. Dry, I saw a fine halo of micro-chip-out under harsh light, the kind of edge you still want to hide under a trim piece. Two tricks improved the finish: a slow initial score pass to establish the kerf, then a second pass to full depth; and a light mist at the cut line. With those adjustments, I was comfortable leaving many exposed edges after a quick rub with a dressing stone.

Glass tile: This is not a glass-specific blade. I tried a few exploratory cuts on scrap glass mosaic and, as expected, edges weren’t as clean as a dedicated glass blade can produce. If your project has significant exposed glass, reach for a glass-rated continuous rim.

Performance on stone

Travertine and limestone: The blade eats through these relatively soft stones quickly. Dry, edge crumble is a risk, especially near corners. Pre-scoring, low feed pressure, and finishing from the visible edge toward waste kept the shoulders intact. Wetting the cut line helped the most and reduced the mushy bruising these stones can show.

Marble: Marble is a bit fussy with any grinder-based cut. The blade will cut it, but I needed to keep pressure feather-light and rely on multiple passes to avoid spalls along the cut line. For finished, exposed edges on marble, a water-fed saw or a blade formulated specifically for marble yields more reliable results. For utility cuts that get hidden by base or trim, this blade is fine with some care.

Granite and denser stone: With granite threshold stock, the blade had enough bite to get through, but it was slower and there was more heat. Short passes and occasional dressing kept it workable. For extended granite work, I’d move to a more aggressive stone blade.

Edge quality and speed

The thin 0.06-inch kerf is the star of the show. It means less material to remove, lower drag, and quicker progress per pass. It also means the blade prefers finesse over force. Push too hard and you’ll hear the pitch rise and see the cut wander slightly; back off and let the diamonds do the work, and it tracks straight with a surprisingly smooth finish for a grinder-based setup. On porcelain, my best edges came from an initial score, followed by one or two shallow passes, not a single deep plunge.

Dust and noise

Dry, dust is inevitable—fine, talc-like and harmful if not controlled. The thin kerf does reduce debris, but it doesn’t eliminate it. A shroud and vac made indoor cuts manageable; outdoors, I kept cuts short and stayed upwind. Wetting the line with a spray bottle cut dust to near zero and improved edge quality, but you’ll need to manage slurry. Noise is typical grinder territory; hearing protection remains mandatory.

Blade life and maintenance

Diamond blades live or die by how quickly they glaze. After a few dozen linear feet of porcelain and some stone thresholds, I noticed the cut slowing and the blade sounding smoother than it should—signs the matrix needed dressing. A few quick passes through a dressing stone (a brick or concrete block can work in a pinch) woke it up instantly. After that, performance remained consistent. For its size and kerf, I’d rate the longevity as solid. It’s not a contractor-grade marathon blade, but it doesn’t feel disposable either. Used with light pressure and occasional dressing, it holds its edge across a small to medium remodel without complaint.

Control and feel

Threading directly onto the grinder keeps the stack compact, which improves control for plunge cuts and tight notches. The blade felt well-balanced with minimal wobble at speed. I particularly liked it for scribing along a marked line for faucets and outlets; the thin kerf makes it easier to “steer” without overcutting. If you’re cutting big quantities of long rips, a table-guided wet saw will always be straighter and calmer, but for on-the-wall modifications and quick trims, this blade shines.

Wet vs. dry takeaways

- Dry cutting is faster to set up and plenty clean with a vac, but finish suffers on brittle tile and soft stone edges.

- Wetting the line dramatically improves edge quality and keeps the blade sharp longer, at the cost of managing slurry.

- For precision finish cuts—especially on marble or highly polished porcelain—I prefer water every time.

Where it excels

- On-site modifications: Trimming a sliver off a laid tile, opening a notch around a valve, or making an L-cut without hauling out the saw.

- Porcelain and ceramic rips that will be covered by trim: Fast, accurate, and tidy enough, with techniques to improve finish when needed.

- Natural stone utility cuts: Thresholds, small returns, and notches, especially if you can mist the cut.

Where it struggles

- Fully exposed finish cuts on marble: Possible, but requires patience and multiple passes. A water-fed saw and a marble-focused blade do better.

- Long, dead-straight rips in hard porcelain: Achievable but slower, and alignment is more sensitive to hand control than a rail-guided saw.

- Incompatibility with many bench-top saws: The 5/8-11 thread is for grinders; it won’t drop onto most saw arbors.

Practical tips

- Score first, then cut. A shallow scoring pass reduces chip-out dramatically.

- Tape the line for brittle surfaces. Masking tape over the cut line helps support glaze on ceramics and soft stone skins.

- Cut from the show face toward waste. It reduces breakout along the visible edge.

- Dress the blade. If the action feels sluggish or overly smooth, expose fresh diamonds before pushing harder.

- Mind RPM. Match your grinder’s speed to the blade’s rating and don’t overspeed; let the tool’s tone guide your feed pressure.

Recommendation

I recommend this DeWalt tile blade for anyone who does tile work with an angle grinder and needs a thin, accurate, and predictable cutter for ceramic, porcelain, and small-stone tasks. Its strengths are clear: a thin kerf that cuts fast with good control, a diamond matrix that holds up well with simple maintenance, and the flexibility to work dry or with a little water when finish quality matters. It’s not the blade I’d pick for exposed finish cuts on marble or for long runs where a rail-guided wet saw would be cleaner and calmer. But as a jobsite companion for real-world tile adjustments and reliable cuts in common materials, it’s a worthwhile addition that earns its spot in the kit.

Project Ideas

Business

Mobile Precision Tile Cut Service

Offer on-site specialty cuts for DIYers and contractors: U/L cuts for outlets, notches around jambs, and tight radius trims. The 4 in blade on a grinder with 5/8-11 arbor fits into cramped spaces; thin kerf reduces dust and rework. Charge per cut or per visit; upsell same-day templating.

Custom Mosaic Logos & Signage

Produce branded tile/stone logos for cafes, lobbies, and pools. The blade’s reduced chipping enables fine lettering and tight inlays in porcelain and marble. Sell design + fabrication packages and ship pre-mounted mesh sheets for easy install.

Shower Niche & Shelf Kit Fabrication

Pre-cut stone/tile panels for niches, corner shelves, and thresholds with polished edges and clean miters. Offer standard sizes and custom orders. Wet cuts keep porcelain edges pristine; thin kerf minimizes waste, improving margins.

Etsy Shop: Premium Stone Coasters/Trivets

Batch-produce chip-free geometric coasters, trivets, and wall art from marble, slate, and porcelain. Leverage the blade for consistent, tight-tolerance cuts and minimal sanding. Offer custom monograms and gift sets for higher AOV.

Backsplash Rescue & Recut Service

Specialize in trimming installed or to-be-installed tiles for last-minute fit issues: outlet misalignments, cabinet reveals, and appliance edges. The small blade handles on-site dry cuts with controlled dust; quick scheduling commands premium pricing.

Creative

Porcelain Mosaic Coasters/Trivets

Cut leftover porcelain and marble tile into precise shards and hexes for mosaic coasters and trivets. The 4 in blade’s thin 1/16 in kerf and diamond matrix minimize chipping, letting you create tight tessellations and clean edges. Use dry for quick batch cutting, then grout and seal for a premium finish.

Circular Floor Medallion

Create an entryway or shower medallion by cutting arcs and petal shapes from contrasting tiles. The small diameter excels at tight radii, while wet cutting keeps porcelain edges chip-free. Assemble on a mesh backing for easy installation.

Slate House Number Plaque

Scribe crisp numerals and borders into slate or honed stone, then cut out with the thin kerf for sharp detail. Chamfer edges and seal; mount with standoffs for a modern look. The blade’s reduced chipping preserves clean lines in brittle slate.

Herringbone Side Table Top

Repurpose tile into a furniture top with precise miters and tight joints. The blade’s thin kerf reduces waste and keeps pattern alignment crisp. Cut dry for speed, then inlay into a wood frame and epoxy finish for durability.

Backlit Onyx Tea Light Holders

Cut and bevel thin onyx strips to form glowing tea light boxes. The diamond matrix and option to cut wet reduce cracking in delicate stone. Polish edges lightly for a translucent glow and assemble with stone epoxy.