Features

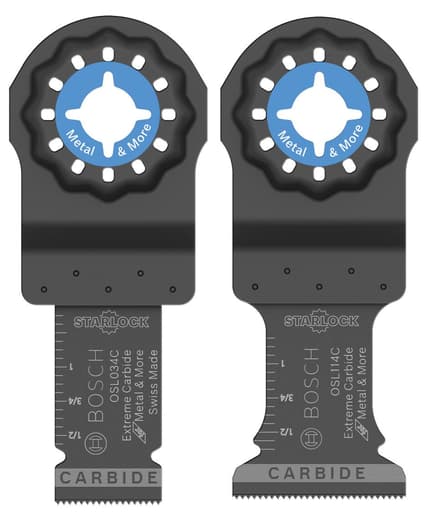

- Contains two carbide plunge-cut blades

- Starlock mounting interface for compatible oscillating multi-tools

- Includes two blade profiles (OSL034C and OSL114C) for different cutting needs

Specifications

| Contents | 1 × OSL034C, 1 × OSL114C |

| Blade Type | Carbide plunge-cut blade |

| Set Size | 2 pieces |

| Pack Quantity | 2 |

| Compatible Interface | Starlock |

Related Tools

Related Articles

Two-piece set of Starlock-compatible oscillating multi-tool blades. The set contains one OSL034C and one OSL114C carbide plunge-cut blade intended for plunge-cutting applications in harder materials.

Bosch Oscillating Multi-Tool Accessory Blade Set (2 pc.) Review

Why I reached for this two-blade set

I reached for the two-piece Bosch carbide blade set the morning I needed to free a rusted door-jamb screw buried under layers of paint. A reciprocating saw would’ve been awkward, and a standard bi-metal oscillating blade dulls fast on abrasive or hardened materials. This set promised a different outcome: two Starlock-mounted carbide plunge-cut blades designed to bite into tougher stuff without giving up control.

If you’re already invested in Starlock, the premise here is straightforward: two profiles (the narrower OSL034C and the wider OSL114C) cover tight plunge cuts and longer straight entries, with carbide teeth that resist wear in abrasive materials and survive occasional metal contact better than typical bi-metal blades.

Setup and compatibility

Installation on a Starlock tool is as simple as it gets—click on, click off, no screws or hex keys. The interface is what makes Starlock appealing: solid torque transfer and a secure, repeatable fit that doesn’t wobble. I used the set across two Starlock tools during testing and appreciated the confidence of a fully seated blade and fast changes between the two profiles.

A quick note on compatibility: these blades require a Starlock-compatible oscillating multi-tool. If your tool uses a different interface, check before buying; adapters won’t help here.

The two blade profiles: where each shines

Narrow profile (OSL034C): This is the blade I used for precision plunge cuts—pocketing into jambs, trimming notches in hardwood flooring, and sneaking into tight reveals. The smaller footprint makes it easier to start a cut exactly where you intend and keep it on line.

Wider profile (OSL114C): With more lateral stability and more teeth in the cut, this one is better for longer plunges and straight-in cuts, like making relief slots in casing, trimming out sections of fiber-cement siding, or widening a box cutout in plywood.

Both are plunge-cut profiles with carbide teeth. They don’t clear chips as quickly as a coarse wood-only blade, but they’re not supposed to. They exist to tolerate abusive materials where a fine-tooth bi-metal or high-carbon blade would fail prematurely.

Cutting performance across materials

Wood and wood with nails: In poplar casing and pine framing, both blades plunge cleanly. I purposely ran into galvanized finish nails and a couple of framing nails; the carbide teeth powered through without a hitch and didn’t noticeably dull after a dozen cuts. In hardwood (oak baseboard with brads), the narrower blade tracked better and produced less chatter.

Drywall and plaster lath: Where carbide really helps is old plaster over wood lath. Plaster’s abrasive fillers are murder on standard teeth; the Bosch blades stayed sharp enough to finish a 12-foot section of lath cuts without the usual “polished” tooth feel. The wider blade left a straighter channel when I needed to run along a stud.

Metals: This is where expectations matter. For non-ferrous and thin ferrous, results were strong. I flush-cut a copper supply stub (soft copper), trimmed two aluminum thresholds, and sliced several zinc drywall screws with no drama. Light-gauge steel (think HVAC sheet up to about 20 gauge) also went fine. On thicker or harder steel, you can do it, but the cost is tooth life. Cutting mild-steel wood screws was acceptable if I kept the tool speed moderate and used a gentle rocking motion to avoid heat build-up. However, hardened structural screws and some stainless fasteners quickly chewed up the tooth edges. That’s not unique to these blades—oscillating tools are a poor choice for lots of hardened steel—but it’s worth calling out. If your task list is “hundreds of hardened screws,” grab a grinder or dedicated metal-cutting blade instead.

Abrasive building materials: I used the wider blade to notch fiber-cement siding and backer board. Carbide teeth are the right call here, and the Bosch set felt purpose-built for this use. You still create dust (wear protection), but the cut stayed controlled and the edge held up well.

Control, accuracy, and feel

Oscillating tools are all about control, and these blades are confidence-inspiring. The Starlock mount keeps everything rigid, so plunge starts are predictable. The narrow blade makes it easy to hit a pencil line inside a tight corner, and the wider one resists wandering when you need a straight-sided pocket. Vibration is typical of a carbide-tooth profile—slightly harsher than a dedicated fine-tooth wood blade—but not fatiguing.

One small advantage to carbide teeth on plunge starts: they’re less prone to skating across painted or finished surfaces compared to very fine bi-metal teeth. Score your line and ease into the cut at a moderate speed and you’ll minimize chatter.

Durability and heat management

In materials these blades are designed for—abrasive composites, wood with the odd nail, plaster—they noticeably outlast standard bi-metal. Across a couple of jobs, I made dozens of contact cuts through nails and drywall screws without a dramatic fall-off in performance. That said, heat is the enemy. If you bury the blade in steel at high speed and lean on it, you’ll cook the teeth and shorten the life quickly. A few tips that helped:

- Keep the oscillation speed moderate in metal and let the carbide work.

- Use a light, slow rocking motion to expose fresh tooth edges and shed chips.

- Take short breaks on long cuts to dump heat.

- Don’t pry with the blade; it chips teeth.

Follow those rules and you’ll get good life for a carbided plunge blade. Ignore them and any oscillating blade—carbide or not—will pay the price.

Where this set fits in a kit

- Remodeling and repair: Ideal for cutting out sections of casing, notching jambs, trimming shims, and dealing with the occasional hidden nail or screw without stopping to change blades.

- Old-house work: Plaster and lath, fiber cement, and mystery fasteners are where the carbide earns its keep.

- Electrical and HVAC: Clean box enlargements in plywood and fiberboard; tidy cuts in light-gauge sheet and vent openings.

If you spend most of your time cleanly crosscutting trim with no metal involved, a dedicated fine-tooth wood blade will cut smoother and faster. If you’re primarily slicing thick steel or hardened fasteners, a grinder or a carbide-grit metal-cutting wheel is more efficient. This set shines in the messy middle where you need plunge control and tolerance for abrasive or mixed materials.

Value and what you’re actually buying

You’re paying for two things: the Starlock convenience and carbide teeth that can survive tasks that eat standard blades. Getting both a narrow and a wider profile in one package makes sense; I swapped between them constantly on a single project. If you only need one profile, buying a single blade may pencil out better. For general remodeling, the two-blade mix covers most plunge scenarios.

Limitations to keep in mind

- Not a miracle cure for hardened steel. Expect chipped teeth if you regularly attack structural screws or thick stainless.

- Requires a Starlock tool—this is a plus if you have one, a non-starter if you don’t.

- Cut quality in fine finish work is good but not glass-smooth; a dedicated fine-tooth wood blade leaves a cleaner edge in pure wood.

Practical tips for better results

- Mark and score your start line; use the narrow blade to establish a pilot, then switch to the wider blade if you need longer parallel sides.

- In metal, reduce speed and use a light, patient feed. If you see discoloration on the teeth, you’re running too hot.

- Clear chips often. A quick back-out mid-cut helps keep the teeth cutting, not rubbing.

- Keep a sacrificial bi-metal blade in the kit for the truly nasty fasteners; save the carbide for the mixed-material cuts it handles best.

Recommendation

I recommend this Bosch carbide blade set for remodelers, repair techs, and DIYers who often plunge into mixed or abrasive materials and want Starlock convenience. The narrow and wide profiles complement each other, the mount is rock-solid, and the carbide teeth hold up well in plaster, fiber cement, wood with nails, and occasional light metal. If your primary need is cutting lots of hardened steel or heavy-gauge ferrous metal, look elsewhere; these blades will do a few such cuts in a pinch, but that’s not their lane. Used where they belong—and with a bit of heat management—they deliver reliable, controlled cuts and a respectable lifespan.

Project Ideas

Business

Mobile Retrofit Cutout Service

Offer on-site plunge-cutting for outlet/switch boxes in tile backsplashes, cement board niches, lockset mortises, and register openings. Carbide blades handle hard materials and surprise nails; price per cut and per material, and market to electricians, remodelers, and DIYers.

Reclaimed Lumber Prep & Sales

Specialize in freeing, trimming, and squaring reclaimed boards by plunge cutting around nails/screws and removing problem sections without damaging tools. Sell prepared stock by the board foot or offer a service fee; the carbide blades reduce downtime from hidden metal.

Van/RV/Camper Mod Installations

Perform precise openings in thin sheet metal, composite panels, and cabinetry for vents, shore-power inlets, lights, and accessories. Plunge starts eliminate the need for pilot holes; use OSL034C for tight corners and OSL114C for longer runs, bundling cutout plus install at a flat rate.

Flooring & Trim Readiness

Provide door-jamb undercutting, register cutouts, and transition slotting for laminate and engineered floors, including in-place adjustments. Carbide teeth tolerate accidental fastener contact; partner with flooring installers and charge per opening or linear foot.

Content + Templates Microbrand

Create tutorial videos comparing OSL034C vs OSL114C in wood-with-nails, fiber cement, and sheet metal, and sell downloadable cutout templates (outlets, vents, plaques). Monetize via affiliate links to Starlock accessories and tool bundles, and offer a paid Q&A or workshop.

Creative

Hidden Magnet Knife/Key Rack

Plunge cut precise cavities in a hardwood board to embed rare-earth magnets and route a hidden wire chase for mounting screws. The carbide blades let you work confidently with reclaimed wood that may contain hidden nails; use the OSL034C for tight pockets and the OSL114C for longer slots so magnets sit flush.

Metal-Inlay Wood Art Panel

Create geometric recesses in hardwood or plywood and inlay thin aluminum or brass sheet for a mixed-media wall piece. The OSL034C handles sharp inside corners, while the OSL114C tackles the longer runs; carbide teeth tolerate incidental contact with fasteners and abrasive plywood glue lines.

Fiber-Cement Address Plaque

Plunge cut crisp numbers/letters into a piece of fiber-cement backer board, then fill with pigmented epoxy for weatherproof contrast. Carbide plunge blades excel in abrasive cement board and let you start and stop cleanly without cracking.

LED Channel Retrofits in Furniture

Add shallow channels for LED strips in shelves or entertainment centers and plunge out clean exit holes for wiring. The carbide blades resist wear when cutting laminates or engineered woods; small-profile OSL034C helps end the channels cleanly without overcutting.

Pallet Coffee Table with Steel Strap Inlays

Upcycle pallet boards by plunge cutting slots for flat steel straps and trimming around embedded nails without blade damage. Use the OSL114C to clear longer inlay paths and the OSL034C to finesse tight corners for a flush industrial look.