Features

- Zirconia abrasive for increased material removal rate compared with fiber resin discs

- Premium abrasive cloth for extended service life relative to fiber resin discs

- Fiberglass Type 27 backing designed for grinding at a 5–15° angle

- Suitable for use on stainless steel and other metal surfaces

Specifications

| Sku | DW8362 |

| Upc | 885911036405 |

| Grit | 60 |

| Arbor | 7/8 in |

| Color | Dark gray / Yellow |

| Weight | 0.23 lb |

| Max Rpm | 12200 |

| Abrasive Type | Coated |

| Disc Diameter | 5 in |

| Pack Quantity | 10 |

| Attachment Type | Arbor |

| Backing Material | Fiberglass |

| Abrasive Material | Zirconia |

| Applicable Materials | Stainless steel |

Related Tools

Related Articles

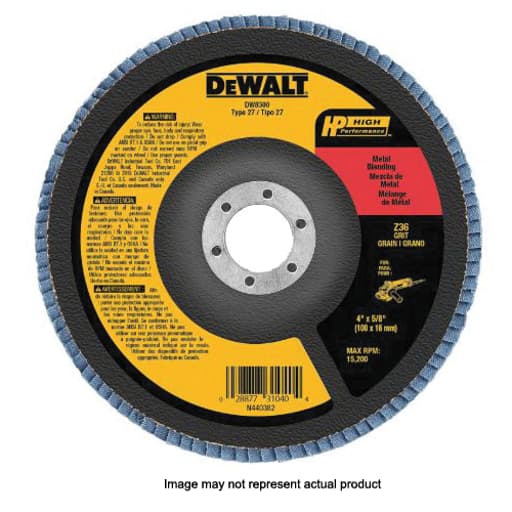

A 5-inch Type 27 flap disc with a 7/8-inch arbor, 60-grit zirconia-coated abrasive on a fiberglass backing. Intended for grinding and material removal on metals such as stainless steel. Rated for use up to 12,200 RPM. Sold in packs of 10.

DeWalt 5" x 7/8" Type 27 flap disc (60 grit) Review

Why this flap disc has found a permanent spot in my grinder bag

I reach for a flap disc more than any other abrasive when I’m cleaning up welds, blending, or knocking scale off steel. After several weeks of using DeWalt’s 5-inch 60‑grit flap disc on mild and stainless projects, I’ve got a clear sense of where it shines and where it doesn’t. It’s a straightforward, no‑nonsense consumable that rewards proper technique with predictable results.

Setup and compatibility

The disc has a 7/8-inch arbor and a fiberglass Type 27 backing, so it drops onto standard 5-inch grinders that use a backing flange and nut—no quick-change hub here. It’s rated to 12,200 RPM, which covers the typical 5-inch grinder’s no-load range. Fit and balance on my grinders (Makita and DeWalt) were solid; no noticeable vibration or wobble even as the disc wore down.

Type 27 is intended for a low grinding angle. I had the best control keeping the disc at about 5–10° to the work, as DeWalt suggests. The structure of the flaps and backing encourages a flatter approach for blending and flush grinding, rather than the aggressive, high-angle stock removal you might attempt with a Type 29.

Performance on steel and stainless

Sixty grit is a versatile middle ground. It removes mill scale and weld spatter fast enough to be productive, yet it leaves a surface that can transition to 80–120 grit without deep scratch chasing. On mild steel:

- Light weld blending: Effective at knocking down bead crowns and blending toes without gouging, provided I kept a light hand and a low angle.

- Edge prep and chamfering: Predictable, straight cuts with good control. It’s easy to maintain a consistent bevel on plate edges.

On stainless steel, dedicated abrasives matter to avoid contamination. I kept one disc exclusively for stainless duty and saw clean, uniform cut patterns. Heat tint was manageable as long as I didn’t lean on the tool. There’s no mention of a cooling additive in this disc’s spec, so I adjusted my technique—lighter pressure, slightly higher travel speed—and had no trouble keeping coloration under control.

If you routinely need to tear through heavy weldments or want the absolute coolest cut on stainless, ceramic flap discs with grinding aids still have an edge. But for general shop work and field repairs, the zirconia blend here holds its own and offers a good balance of speed and cost.

Material removal rate and feel

Compared with standard aluminum-oxide flaps, this disc is noticeably more eager to bite. Zirconia’s self-sharpening behavior helps it stay cutting as the flaps wear. The disc doesn’t glaze easily, but like any flap, it can smear if you:

- Increase the angle past ~15°

- Stall the rotation with heavy pressure

- Dwell in one spot to chase a defect

The sweet spot was moderate pressure with a consistent sweep. The disc stayed quiet and stable, and I could “read” the cut by listening for the change in tone as it loaded and cleared.

Life and durability

Anecdotally, I’m seeing longer life than budget aluminum-oxide flaps and on par with other mid‑tier zirconia discs. The premium cloth backing holds the flaps well; I didn’t experience premature shedding or delamination. The fiberglass plate stayed intact even after a couple of accidental edge bumps against fixtures—no cracking or “egging” of the center hole.

Like most 60‑grit flaps, the last third of life is for lighter work: deburring, edge breaking, and surface prep. Don’t expect heavy stock removal once the outer flaps are mostly consumed. That’s normal behavior, not a defect.

Surface finish

On mild steel, the scratch pattern is consistent and easy to refine. Moving from this disc to an 80‑grit flap or a conditioning wheel gives a near-paint‑ready finish with minimal work. On stainless, the finish is uniform, but if you’re chasing cosmetic perfection on visible work, you’ll still follow with higher grits or non-woven abrasives to remove linear striations.

Ergonomics and balance

The disc is relatively quiet and runs smoothly. Fatigue-wise, keeping the angle low reduces chatter and kickback, especially when blending welds on tubing or inside corners. If you’re used to pushing hard with hard-bond grinding wheels, recalibrate—flap discs reward finesse. Less pressure and more movement equals better control and longer life.

Where it doesn’t excel

- Heavy aluminum removal: Zirconia flaps tend to load on soft non‑ferrous materials. For aluminum, use a disc designed for non‑ferrous with a dedicated lubricant or open‑coat structure.

- Maximum aggression: If your day is removing large welds all shift, a ceramic flap disc will cut cooler and last longer under constant pressure.

- Tight access: Type 27 is great for flat work and gentle contours, but it’s not ideal for sharp inside corners. A smaller diameter disc or a die‑grinder solution is better there.

Practical tips from the bench

- Keep your angle between 5–10° and maintain motion. This disc rewards technique with a flatter, cleaner blend.

- Use dedicated discs for stainless to prevent cross‑contamination.

- Let the abrasive cut. If you see heat tint quickly on stainless, lighten up and increase travel speed.

- Store discs flat and dry to protect the fiberglass backing.

- Dress edges intentionally: roll onto the edge rather than digging in; it extends disc life and preserves geometry.

Value and pack size

It comes in a 10‑pack, which makes sense for small shops and pros who go through abrasives regularly. The performance sits in the “workhorse” middle ground—noticeably better than bargain discs, not as specialized (or expensive) as premium ceramic. If your workload is split across mild steel fabrication, stainless kitchen or architectural pieces, and general repair, this is the kind of disc you’ll use up, not stash.

Safety and compatibility notes

- Verify your grinder guard is suitable for Type 27 and that your tool’s max RPM doesn’t exceed 12,200.

- Always wear eye, ear, and respiratory protection; flap discs throw fine particulate, especially on stainless.

- Check flange condition—worn or dirty flanges can introduce vibration and premature disc wear.

Who it’s for

- Fabricators and welders looking for a reliable, everyday 60‑grit for blending and prep

- Mechanics and maintenance techs who need a durable disc for scale removal, bracket cleanup, and general steel work

- Hobbyists stepping up from aluminum‑oxide flaps to something that cuts faster and lasts longer without jumping to high‑cost ceramic

Bottom line

The DeWalt 5‑inch 60‑grit flap disc is a steady performer: fast enough to be productive, controllable enough to avoid rework, and durable enough to justify buying it in packs. It favors good technique and rewards a low, consistent angle with a clean blend on both mild and stainless steel. While it’s not the ultimate choice for heavy production grinding or non‑ferrous work, it fills the “do most things well” slot that many shops need.

Recommendation: I recommend this disc for everyday metalwork—weld blending, edge prep, and surface conditioning on steel and stainless—especially if you prefer a Type 27 for flatter work. If your focus is high-volume stainless fabrication where heat control and lifespan are critical, step up to a ceramic disc with a grinding aid. For general use, this DeWalt hits the right balance of speed, finish, and value.

Project Ideas

Business

Mobile Stainless Finish & Repair

Offer on-site blending and refinishing for restaurants, breweries, and commercial kitchens. Use the 60-grit zirconia flap disc to remove weld discoloration, scratches, and dents on stainless counters, rails, and equipment, then step through finer grits for a matched satin finish. Bill per hour plus consumables.

Weld Cleanup Service for Contractors

Partner with fabricators and GC’s to provide fast weld cleanup on railings, gates, and structural details. The Type 27 disc lets you grind at a 5–15° angle to flush-blend fillets, remove spatter, and prep for paint or powder coat. Sell per linear foot or per assembly with a ‘ready-for-finish’ guarantee.

Brushed Steel Wall Art Shop

Create and sell plasma- or laser-cut wall pieces with signature flap-disc textures on Etsy and at markets. Use the 5 in, 60-grit disc to add directional grain and swirl patterns that catch light, then clear or tinted clear-coat. Offer custom names, maps, and logos with quick turnaround using 10-pack discs for efficiency.

Rust and Paint Removal Detailing

Provide rust remediation for trailers, gates, lawn equipment, and utility trucks. The zirconia disc chews through corrosion and old coatings fast, leaving a paint-ready profile. Package pricing: surface prep + primer application, with mobile service upsells.

Intro Knife-Making Workshops

Host weekend classes where students rough-grind a camp or kitchen knife from blanks using angle grinders with 60-grit flap discs. Charge per seat including consumables (10-pack discs), then upsell finishing kits or advanced classes.

Creative

Industrial Steel Side Table Base

Fabricate a minimalist side table base from 1x1 in steel tube, then use the 5 in Type 27 flap disc (60 grit) to blend welds, radius corners, and create a uniform brushed texture. Grind at the recommended 5–15° angle to avoid gouging, then clear-coat to lock in the dark gray/brushed contrast.

Brushed Metal Wall Art

Cut a skyline or geometric pattern from mild steel sheet, remove mill scale, and add directional grain and light-catching swirl patterns with the 60-grit zirconia disc. The consistent scratch pattern becomes a design element under a translucent dye or clear finish.

Stainless Garden Sculpture

Assemble scrap 304/316 stainless into abstract forms, TIG/MIG weld, then use the zirconia flap disc to quickly blend welds and create a satin surface that won’t contaminate stainless. The 5 in disc’s control helps shape contours before final Scotch-Brite finishing.

Knife Blank Bevels and Profiling

Rough-in bevels and refine profiles on knife blanks or machetes. The 60-grit zirconia cloth removes stock efficiently without overheating as quickly as hard wheels. Follow with finer grits and hand sanding for a clean, even bevel.

Custom BBQ/Smoker Hardware

Build handles, hinges, and brackets for smokers and grills from flat bar and rod. Use the flap disc to blend welds, round edges for comfort, and create a uniform brushed finish on both steel and stainless components before seasoning or coating.