Features

- Zirconia abrasive for faster material removal compared with fiber-resin metal sanding discs

- Premium abrasive cloth for longer service life than fiber-resin metal sanding discs

- Type 29 fiberglass backing designed for grinding at 20–25°

Specifications

| Disc Diameter | 4-1/2 in |

| Arbor Size | 7/8 in |

| Grit Size | 24 |

| Disc Type | Type 29 |

| Abrasive | Zirconia |

| Backing | Fiberglass cloth (supports 20–25° grinding angle) |

Related Tools

Related Articles

Flap disc intended for angle grinding (typically 20–25°). Uses zirconia abrasive on a cloth-backed construction to provide aggressive material removal and extended life compared with conventional fiber-resin metal sanding discs. Common applications include weld blending, removing weld slag, deburring, surface preparation, and edge blending/chamfering.

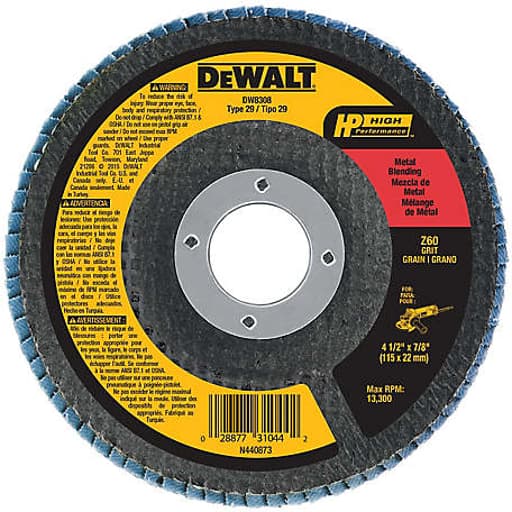

DeWalt 4-1/2" x 7/8" 24g Type 29 Flap Disc HP Review

Why I reached for this flap disc

I had a mix of tasks on the bench—knocking down MIG welds on a trailer frame, chamfering plate edges for fit-up, and cleaning up some stubborn mill scale before paint. For jobs like that, a coarse, Type 29 flap disc is my go-to. I grabbed the DeWalt flap disc (DW8330) because its 24-grit zirconia is aggressive enough to move material quickly, and the conical Type 29 profile suits the 20–25° angle I typically run on a 4-1/2" grinder. It’s the kind of disc that promises fast stock removal without the short life I associate with fiber-resin sanding discs.

Specs and build

This disc is a 4-1/2-inch diameter with a 7/8-inch open arbor, so it fits standard grinders without a hub. The abrasive is zirconia on a premium cloth backing, arranged on a fiberglass plate. The Type 29 shape (conical) is designed to cut best at a steeper angle—20 to 25 degrees. The 24 grit is coarse, leaving a deep scratch pattern appropriate for heavy grinding, weld blending, and edge bevels. It’s built to take the pressure required for those jobs, and the fiberglass backing keeps the disc rigid and stable without a lot of flex.

Stock removal and finish quality

On mild steel, this disc is a hog. I used it to flatten weld beads flush to surrounding sheet and to contour transitions on heavier plate. It bit immediately, even on hard bead crowns, and kept cutting with minimal glazing thanks to the zirconia’s self-sharpening characteristics. Compared with fiber-resin sanding discs, the cut rate is faster and stays more consistent as the disc wears.

The scratch pattern is what you’d expect from 24 grit—coarse and linear. For structural work or paint-ready prep after a step-down, it’s ideal. If I’m chasing a better cosmetic finish, I follow up with a 60- or 80-grit flap disc or a surface conditioning disc. For edge bevels, the Type 29 profile is handy: you can roll your wrist slightly and use the outer band to establish a clean, even chamfer without digging in.

Control and comfort

Balance is a big deal with flap discs, especially when you’re leaning on the grinder for extended periods. This one runs smooth with low vibration on my 4-1/2" grinder, which helps keep the contact patch predictable and reduces chatter marks. The Type 29 geometry encourages that higher approach angle; it feels natural to ride the outer third of the disc. The fiberglass backing stays cool enough to touch between passes, and there’s no “wobble” as the disc wears down.

Visibility is good because the conical shape keeps the hub area away from the work, letting you see the leading edge. That makes it easier to blend weld toes without gouging. It also helps when feathering edges along flat bar—you can sneak up on flush without the disc suddenly skidding.

Durability and wear

Zirconia on a cloth backing is a proven recipe for long life. I ran this disc through multiple tasks—weld removal, mill scale, and some rust—before the flaps shortened to the point where the backing started to make contact. The cut rate stayed useful most of the way down. Unlike fiber-resin discs that glaze and then suddenly fail, this one wears progressively, and the flaps shed grit as expected to expose new cutting edges.

Heat control matters for disc life. With a light-to-moderate touch and that recommended 20–25° angle, the disc resisted loading and kept cutting. Pressing too hard will still shorten its life and risk burning the work, but it’s more forgiving than aluminum oxide discs in the same grit. The fiberglass backing didn’t delaminate and remained stable; I never had a flap lift prematurely.

Material range and limitations

Where this disc shines:

- Mild and carbon steel: weld blending, slag cleanup, rust removal, edge beveling

- Stainless: effective for stock removal; keep the pressure moderate to manage heat and avoid discoloration

- Mill scale and heavy coatings: cuts through quickly before a finishing pass

Where I back off:

- Aluminum: it will cut, but it loads quickly. Use a dedicated non-loading disc or a stick-wax lubricant if you must proceed.

- Tight inside corners or small fillets: the Type 29 profile can’t reach; a Type 27 or a small-diameter accessory is better.

- Finishing to a cosmetic surface: 24 grit is a first step. Plan to step down to 60–80 grit and/or a conditioning disc.

I also put it to work cleaning excess mortar off brick steps. It removed the high spots fast and was easy to control, but masonry is abrasive in a different way and will shorten disc life compared with steel. If you do this, keep the angle tight and use light pressure to avoid gouging the brick.

Tips for best results

- Run at a 20–25° angle to match the Type 29 profile; this keeps the disc on its strongest area and controls heat.

- Use moderate pressure and let the zirconia do the work. If you see the surface darkening or the disc starts to skate, lighten up or increase the angle slightly.

- Move consistently and keep the disc in motion to avoid gouges. For weld toes, overlap passes by about half.

- Clear swarf. A quick tap or air blast helps prevent loading and maintains cut rate.

- Step down your grit sequence after heavy stock removal if you need a paintable surface without deep scratches.

- Keep the guard on and wear full PPE—the cut rate is high, and so is debris output.

Value and alternatives

Zirconia flap discs cost more than basic fiber-resin sanding discs, but the productivity gains and longer life often make them cheaper per job. This disc in particular earns its keep on heavy work. If your tasks are mostly light deburring or finishing, it may be overkill; a 60- or 80-grit flap disc will leave a friendlier surface and still last a long time. If you need to work flatter with more control on broad surfaces, a Type 27 flap disc can be easier to keep parallel. For deep reach or very tight spots, pair this with a carbide burr or smaller accessory.

What you’re paying for here is consistent cut rate, predictable wear, and a backing that doesn’t fight you. In my experience, the longevity offsets the upfront cost, especially on weld-heavy projects.

The bottom line

The DeWalt flap disc (DW8330) is a straightforward, reliable choice when you need to remove a lot of metal quickly and with control. The 24-grit zirconia cuts fast, the Type 29 profile rewards the correct angle with smooth tracking, and the fiberglass backing keeps things rigid and stable. It’s not a finishing disc and it’s not meant for tight corners, but within its lane—weld blending, slag removal, deburring, and edge prep—it performs exactly as I want a heavy-grit flap disc to perform.

Recommendation: I recommend this disc for anyone doing regular weld cleanup, edge beveling, or aggressive surface prep on steel. It delivers fast stock removal, steady wear, and good control at the right angle. If your work leans toward fine finishing or soft metals, choose a finer grit or a specialized disc; otherwise, this 24-grit Type 29 is a dependable workhorse that pays for itself in productivity.

Project Ideas

Business

Mobile Weld Blending & Edge Rounding

Offer on-site weld cleanup for fabricators and contractors. Use the 24g Type 29 disc to blend fillets, remove slag, and break sharp edges at 20–25°, delivering paint- or powder-ready surfaces billed per foot or per joint.

Rust, Paint, and Mill-Scale Removal Service

Prep gates, railings, stair stringers, and patio furniture by stripping scale and coatings with zirconia flap discs, followed by primer and finish as an upsell. Package pricing per square foot with add-on repairs.

Custom Grind-Textured Signage & Decor

Produce steel signs and restaurant decor that feature distinctive grind patterns. Use the flap disc for surface prep, edge bevels, and weld blending; offer clear, tinted, or patina finishes and LED backers.

Fabricated Bracket and Table-Leg Kits

Manufacture and sell ready-to-finish bracket sets, shelf supports, and steel table legs. Fast edge chamfering and weld blending with the 24g disc shortens cycle time; ship as raw steel or sealed kits via online marketplaces.

Shop Fixture Deburring & Refurb Service

Provide subscription-based maintenance for local machine/fab shops: deburr parts, round edges on jigs/fixtures, and blend repaired welds. The aggressive flap disc reduces turnaround and improves safety on handled parts.

Creative

Grind-Textured Steel Wall Art

Create abstract wall panels by laying grind patterns (swirls, crosshatch, directional brush) on sheet steel using the 24g Type 29 flap disc at a 20–25° angle. Frame with angle iron, blend welds smooth, then clear-coat for a reflective, industrial finish. Add backlighting for depth.

Industrial Shelf Brackets & Hardware

Fabricate heavy-duty brackets from flat bar or angle. Use the zirconia flap disc to bevel edges, radius corners, and blend welds for a professional look. Finish with a blackened or clear-oiled patina for a clean, rugged aesthetic.

Custom Fire Pit or Ring

Cut and roll plate into a ring, add plasma-cut motifs, then use the flap disc to prepare bevels, blend seams, and soften sharp edges. The aggressive 24g grit speeds fit-up and cleanup before high-heat paint or seasoning.

Scrap Metal Garden Sculpture

Transform scrap into flowers, birds, or abstract forms. Quickly remove rust and mill scale, shape petals and feathers, and blend spot welds using the Type 29 disc. Finish with exterior clear coat or patina for outdoor display.

Knife Blank Profiling and Chamfering

Rough-profile knife blanks and add consistent chamfers prior to heat treat. The coarse zirconia disc removes stock fast and deburrs edges; switch to finer grits for bevel grinding and finish work.