Features

- Worm‑drive gearing with electric brake

- 15 A Dual‑Field motor for cooler operation under load

- Self‑lubricating full‑house chain with tool‑less tensioning

- Magnesium housing to reduce weight

- 14-1/4 in cutting depth at 0°

- Includes guide bar, full‑house chain, auxiliary handle, saw stand, and chain sheath

Specifications

| Includes | SPT55 saw, SKILSAW 56T full‑house chain, 16 in guide bar, auxiliary handle, saw stand, chain sheath |

| Blade Type | SPTA1500 Full House 56 DL 3/8" Chain |

| Motor Gear | Worm Drive |

| Tool Width | 7 in |

| Cord Length | 8 ft |

| Handle Type | Auxiliary |

| Tool Height | 25.5 in |

| Tool Length | 28 in |

| Speed Rating | 6300 rpm |

| Wattage/Power | 3.3 hp |

| Bevel Capacity | 0 - 60° |

| Blade Location | Left |

| Current Rating | 15 A |

| Voltage Rating | 120 V |

| Blades Included | Yes |

| Bar/Chain Length | 16 in |

| Frequency Rating | 60 Hz |

| Housing Material | Magnesium |

| Cutting Depth At 0° | 14-1/4 in |

| Cutting Depth At 45° | 8-3/4 in |

| Cutting Depth At 60° | 5-1/2 in |

| Maximum Rpm (No Load) | 6300 RPM |

Related Tools

Related Articles

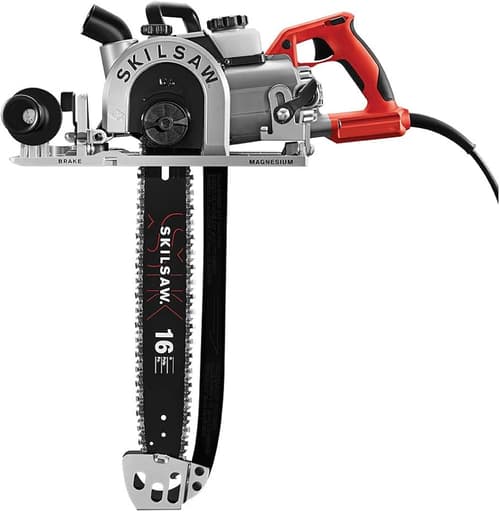

16-inch worm-drive carpentry chainsaw designed for heavy cutting tasks. It uses a worm-drive gearset with an electric brake and a 15 A Dual‑Field motor intended for sustained operation. The saw has a self‑lubricating full‑house chain, tool‑less chain tensioning, and a magnesium housing to reduce weight while maintaining durability. It includes a guide bar, chain, auxiliary handle, saw stand and chain sheath.

Skil 16 in Worm Drive Carpentry Chainsaw Review

Why I reached for this saw

I spend a fair amount of time cutting heavy timbers, engineered wood products, and oversized stock that a standard 7-1/4 inch saw simply can’t touch. For those tasks, the Skilsaw carpentry chainsaw has become my go-to. It’s essentially a purpose-built, left-blade worm-drive with a bar and chain, designed to make deep, accurate cuts in big material while keeping the control and layout familiarity of a circular saw. It isn’t a general-purpose chainsaw, and it isn’t a replacement for a framing saw—it sits in that valuable middle ground where you need 14 inches of depth and a stable shoe to keep things square.

Build, setup, and first impressions

Out of the box, the setup is straightforward: bar and full-house chain, auxiliary handle, saw stand, and chain sheath all included. Add bar and chain oil, set chain tension with the tool-less adjuster, and you’re cutting in a couple of minutes. The magnesium housing matters here; it keeps the saw manageable in hand without feeling flimsy. It’s still a big tool with a long bar, but the balance is good, especially with the left-side blade orientation that gives a clear sightline for right-handed users.

The worm-drive gearset and 15 A Dual-Field motor are a familiar Skilsaw pairing—torquey and cool-running. The electric brake is quick and confidence-inspiring, which is essential on a chain-driven tool. The 8 ft cord is adequate for bench and site work, though I run it on a 12-gauge extension to keep voltage drop in check.

Power and cut quality

In dense stock—12x posts, 6x6, and LVL—the saw hasn’t bogged on me. It’s rated at 3.3 hp with a 6300 rpm max no-load speed, and in real terms that translates to a steady, controllable feed rate rather than blistering speed. The full-house chain (more teeth, tighter sequence than a typical skip chain) is the star: it leaves cleaner, squarer faces with far less tearing than I’d expect from a chain. End grain on structural timbers is remarkably tidy, which matters if you’re leaving cuts exposed or fitting joinery that needs to register accurately.

Depth is the reason to own it: 14-1/4 in at 0°, 8-3/4 in at 45°, and 5-1/2 in at 60°. I’ve used those bevel capabilities to notch, make compound cuts on oversize rafters, and square off mantel stock where a small saw would require multiple flip cuts. The large shoe gives you a flat, stable reference; it feels like a circular saw scaled up for timber work, which is exactly what I want.

The chain stops fast when I release the trigger, and the worm drive keeps the cut smooth with little chatter. Tool-less chain tensioning has held up well; I check tension at each oil top-up and haven’t had any mid-cut slack issues.

Accuracy and visibility

On layout-critical work, the saw’s geometry is predictable. The bevel and depth scales are honest, and once I set a stop, I trust it. That said, a few realities come with the format:

- The chain runs up on the leading edge of the bar, which throws chips up and forward. That tends to collect in front of the shoe and can obscure the line if you’re relying solely on the top sight notch.

- The distance between the top notch and the actual cut is larger than a conventional circular saw, so counting on the notch alone for precision isn’t ideal.

My solution has been to use a straightedge or fence for long, critical cuts, or strike wide layout marks and score with a knife first for a defined reference. The motor’s cooling airflow does blow some dust off the line, but not all of it. There’s a dust port for extraction, and it helps, though I’ve found the connection less secure than I’d like—movement can knock a friction-fit hose off. A snug adapter, a wrap of tape, or a hose with a locking cuff makes a noticeable difference.

Safety, controls, and handling

The two-stage trigger safety takes a little retraining of the hands, but it’s appropriate for a tool like this and becomes second nature. The auxiliary handle is useful, and being able to reposition it for right- or left-hand biased cuts adds stability on awkward timbers or when you’re pushing a long bevel.

A riving knife and tip guard do their job: the knife keeps the kerf from closing on the chain, and the guard protects the nose when you set the saw down. In very wet or tensioned stock where the kerf tries to pinch, the riving knife can hang up. I keep hardwood or plastic wedges at hand and drop one into the cut when I sense pressure building; it keeps the cut moving and prevents binding without defeating the safety hardware.

Despite the magnesium build, this is still a two-handed saw that rewards deliberate technique. The good news is that the worm-drive torque means you don’t have to force it—let the chain work and it tracks straight. Vibration is lower than you might expect from a chain, and noise is… well, it’s a 15 A worm-drive with a chain. Hearing protection isn’t optional.

Dust and chip management

Self-lubrication is effective, and the chain stays happy on long cuts in dry hardwoods and LVL. As with most oiler systems, you’ll see some seepage when the saw is stored. I keep the chain sheath on and park the saw on its stand over a rag or tray when it’s off the truck, and I don’t transport it with a full reservoir. The dust port is a welcome addition for shop-use cleanup and line visibility, but it would benefit from a more positive hose connection; with a standard shop vac hose, it’s easy to dislodge if you twist the saw mid-cut.

Where it shines—and where it doesn’t

- Timber framing and heavy structural cuts: This is the use case. It square-cuts 12x and larger stock cleanly and bevels accurately where a standard saw can’t reach.

- Engineered wood products: LVL, PSL, and chunky glulams cut cleanly with minimal tear-out. The large shoe helps keep faces flush when you’re cutting wide beams on edge.

- On-site joinery: Deep notches, birdsmouths on large rafters, and compound miters are all doable without kludgy multiple passes.

It’s less suited to:

- General framing: It’s overkill for 2x lumber and slower than a dedicated framing saw.

- Tight-clearance work: The long bar and overall length make it awkward in cramped conditions.

- Dust-critical interior cuts without extraction: You’ll want a vac and a secure hose connection for line visibility and cleanup.

Maintenance and consumables

The full-house chain sharpens like any 3/8 in chain, but you’re sharpening more cutters. I keep a sharp spare on hand and swap when the cut slows rather than fighting a dull edge on engineered products. Chain tension stays put with the tool-less adjuster; I give it a quarter-turn after the first warm-up cut on a fresh chain and it settles in. Bar and chain oil consumption feels normal for the bar length. Check the reservoir regularly on long runs—running dry isn’t worth the heat.

Expect some oil weep in storage, as mentioned. It’s typical, not a defect, but it does mean you should store the saw carefully to avoid a mess.

Pros and cons

Pros:

- Serious depth of cut with a stable, circular-saw-like shoe

- Clean, square surfaces from the full-house chain

- Worm-drive torque and effective electric brake

- Tool-less chain tensioning that actually holds

- Magnesium housing keeps weight manageable

- Accurate bevel range from 0–60°

Cons:

- Line-of-cut visibility can be compromised by chip throw; plan for extraction or a straightedge

- Dust port connection is easy to knock loose without a locking cuff

- Riving knife can bind in closing kerfs; wedges help

- Some oil seepage in storage (typical of oiler systems)

- Size and weight make it a specialty tool rather than a daily driver

Recommendation

If you routinely cut large timbers, engineered beams, or oversized stock where depth, accuracy, and a flat shoe matter, I recommend the Skilsaw carpentry chainsaw. It’s powerful, predictable, and produces cleaner cuts than I expected from a chain-driven tool. You’ll want to adapt your workflow—use a straightedge for critical lines, keep wedges handy, and sort out a secure vac connection—but the trade-offs are small compared to the capability it adds.

If your work rarely exceeds 4x material, a standard worm-drive circular saw is faster and more practical. For everyone else working in big stock, this tool earns its space on the truck by replacing workarounds with one clean, controlled pass.

Project Ideas

Business

On-Site Beam Notching Service

Offer mobile notching and joinery prep for timber framers, deck builders, and pergola contractors. Quickly cut birdsmouths, housings, and seat cuts in large stock with single-pass depth and precise bevels, reducing their setup time and boosting project throughput.

Reclaimed Timber Resizing & Squaring

Specialize in converting salvaged beams into ready-to-use architectural stock. Provide cut-to-length, end-squaring, and defect removal on site; the 14-1/4 in cutting depth handles big timbers efficiently, turning raw salvage into premium, install-ready pieces.

Landscape Timber Fabrication

Serve hardscape installers with custom cuts for outdoor stairs, retaining walls, and garden structures. Deliver notched step blocks, interlocking retainer pieces, and precision-cut landscaping elements that speed up installations and improve fit and finish.

Event & Set Carpentry Pop-Ups

Provide rapid fabrication of rustic arches, photo backdrops, and timber features for weddings, pop-ups, and film/theater sets. The saw’s torque and electric brake allow fast, clean accent cuts in heavy stock, enabling eye-catching builds under tight timelines.

Heavy-Duty Crating & Skid Building

Build custom machinery skids, blocking, and transport cradles for movers and manufacturers. Large-section cuts and long, straight rips in thick timbers enable robust, tailored packaging that protects high-value equipment and supports specialized logistics needs.

Creative

Timber-Framed Garden Pergola

Design a bold pergola using 6x6 or 8x8 posts and beams with clean through-cuts and compound angles. The saw’s 14-1/4 in depth and 0–60° bevel capacity let you form seat cuts, birdsmouths, and decorative rafter tails in large stock for a refined, architectural look.

Interlocking Beam Bench + Planter Set

Create a modular outdoor seating system from chunky beams that lock together via crisp notches and through-slots. The full-house chain leaves smooth kerfs that become part of the design language, while worm-drive torque keeps long, straight cuts accurate for a puzzle-like fit.

Faceted Geometric Yard Sculpture

Sculpt large timbers into polyhedral forms by combining angled rip and crosscuts to reveal facets and grain. Use the bevel range to create repeating planes and textures; the electric brake helps control each facet transition for a clean, faceted aesthetic.

Live-Edge Timber Portal

Build a dramatic entry frame from live-edge slabs or squared timbers, trimming ends and cutting oversized mortise-style openings for a portal effect. The magnesium housing reduces fatigue while executing long, straight cuts that showcase the mass and grain of the material.

Oversized Puzzle Coffee Table

Laminate or stack thick timbers, then cut interlocking profiles and negative spaces to form a sculptural coffee table. The tool-less chain tensioning helps keep cut quality consistent across intricate, repeating joinery that reads like giant puzzle pieces.