Features

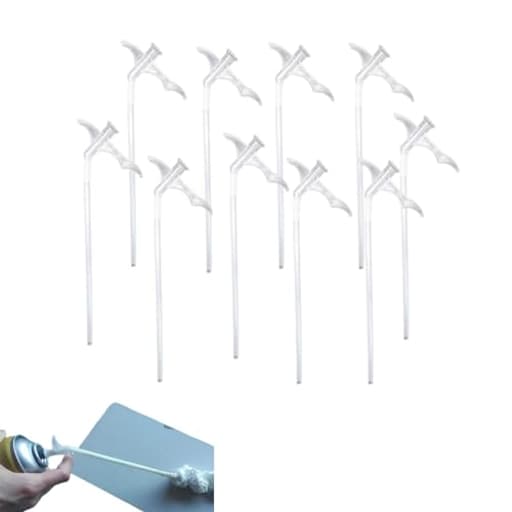

- DURABLE MATERIAL: Our spray foam replacement tubes are crafted using plastic materials, which is extremely durable. Spray foam tubes are available in clear coloring. It is replacement tubes for all major brands of DIY spray foam. It is helpful to fill-n-seal gaps.

- SIZE: The spray foam tubes length is about 18.5cm/7.28inch, the connector mouth diameter is about 1.1cm/0.43inch.

- TEN TUBES PER PACK: Spray foam tubes are available of 10 tubes in one pack. They can be used to fill, seal, and insulate gaps up to 1 inch - 10 foam tube replacement tubes for all major brands of DIY spray foam insulation.

- EASY INSTALLATION: The spray foam tubes can be installed easily and quickly. It can be mounted single-handedly without the use of any complicated tools or hacks. Just take off the old one and replace with the new one.

- PERFECT REPLACEMENT: Spray foam tubes are widely used as replacement tubes for all major brands of DIY spray foam. After using spray foam, leave clogged assembly attached. When ready to use again, take off the clogged tube assembly & replace with the new spray foam replacement tube.

Specifications

| Color | transparent |

| Size | free size |

Related Tools

Ten clear plastic replacement nozzle tubes for use with standard DIY spray foam cans, each about 18.5 cm long with a connector mouth diameter of about 1.1 cm. They provide a controlled outlet to fill, seal, and insulate gaps up to about 1 inch and can be installed single-handedly as a direct replacement for clogged or worn tubes, compatible with most major DIY spray foam brands.

UXELY 10Pcs Spray Foam Tubes Nozzle, Gap Filling Insulating Foam Spray Replacement Tube, DIY Foams Spray Accessory for DIY Spray Foam Clear Review

Why I Tried These Replacement Foam Nozzles

On small insulation jobs, the weakest link is often the plastic straw. Once the foam sets inside, that’s it—you’re done. I picked up this 10-pack of clear replacement spray foam tubes to see if I could save half-used cans, keep projects moving without gummed-up applicators, and get better control over beads in tight spots. Over a couple of weekends sealing a basement rim joist, door frames, and a handful of plumbing penetrations, these simple tubes ended up being genuinely useful—nothing fancy, just dependable, disposable accessories that solve an everyday nuisance.

What They Are

This is a pack of ten clear plastic replacement tubes sized for standard DIY spray foam cans (the typical straw-dispense cans you find at any home center). Each tube is about 18.5 cm (7.28 inches) long with a connector mouth that fits snugly over the can’s valve outlet. There’s no trigger or valve built into the tube—it’s just the straw—so all flow control still happens at the can’s built-in trigger. The clear material is more helpful than it sounds: you can see foam moving, spot air pockets, and know immediately when a tube is compromised or starting to clog.

Setup and Compatibility

Installation is as straightforward as it gets:

- Shake the can thoroughly per the can’s instructions.

- Push the tube onto the can’s outlet until it bottoms out.

- Give it a slight twist for a secure fit.

I tested these with two common DIY foams (a general-purpose gap filler and a “window and door” low-expansion formula). The tubes seated cleanly and didn’t blow off under pressure. The 1.1 cm connector mouth size seems to match the standard DIY valve stem without needing adapters. As a note: these are not for pro-style foam guns—only for straw-dispense cans.

One perk is using them to preserve a can for later. After spraying, I left the used, clogged tube attached on the can to act as a temporary seal. On the next session, I popped off the old straw and snapped on a fresh one. That let me return to a half-used can with minimal fuss and no drips at the valve.

In Use: Flow and Control

For general gap filling—from hairline cracks up to around 3/4 inch—the tubes deliver a predictable bead. The clear plastic gives you immediate feedback: if you see the foam hesitate or bubble, you know to pause and let pressure equalize. The stock tip is blunt, which is fine for most jobs. For precise control around electrical boxes or trim, I snipped the end at a shallow angle to create a finer, more directional tip. That small tweak made a noticeable difference in bead accuracy.

The 18.5 cm length is decent for reaching into rim joists and behind studs without contorting your wrist. However, for deep cavities or awkward soffits, it can be a touch short. On one run, I press-fit a short piece of flexible vinyl tubing over the end to gain a few inches—worked in a pinch, but watch for any restriction at the joint.

One thing to remember: the tube doesn’t change the foam’s expansion characteristics. If you’re working around doors and windows, you still want a low-expansion foam; these tubes simply give you a controlled path to place it.

Durability and Reusability

This is sturdy, disposable plastic—stiff enough to resist kinking under gentle curves, but not so rigid that a sideways bump will snap it. That balance is right for straw work. You could theoretically clean a tube immediately with a solvent while the foam is still wet, but in practice the workflow that makes sense is single-use. The pack-of-ten approach encourages you to toss a clogged tube guilt-free and keep moving, which is exactly the point.

I had no issues with blowback at the connection or micro-cracks at the tip. If you bend it sharply, it will crease and restrict flow, so keep your curves smooth. The transparency is deceptively helpful: the moment curing starts inside the straw, you’ll see the flow constrict, which is your cue to swap.

Where These Shine

- Multi-phase projects: If you’re sealing a basement one bay at a time over a week, these keep your can in service. Leave the old straw on as a cap, then switch to a fresh one next session.

- Tight quarters: A snipped, angled tip and the clear body make it easy to place foam exactly where you want it without overfilling.

- Clean handoffs: On job sites or shared workshops, it’s easier (and cheaper) to swap a straw than to wrangle a sticky, half-clogged one.

Limitations and Workarounds

- Not for pro guns: If you rely on a reusable foam gun with canisters, these aren’t for you. Gun systems offer better long-term control and true reusability at a higher upfront cost.

- Length limits: The 18.5 cm reach won’t solve every access problem. For deep cavities, an extension sleeve or a length of compatible tubing over the tip helps—just keep the joint secure and straight.

- Waste: They’re disposable plastic. The tradeoff is convenience and less wasted foam from prematurely expired cans. If minimizing waste is paramount, a pro gun and cleaner might be a better system.

- No flow modulation at the tip: All control is via the can’s trigger. If you need very fine control regularly, consider a gun-applied setup.

Tips for Best Results

- Warm the can: Slightly warm (room temperature) cans flow more evenly. Cold foam often sputters.

- Shake thoroughly: Inadequate mixing makes for inconsistent bead size and unpredictable expansion.

- Pre-cut a tip: Keep one straw with a fine angle cut for precision work and another uncut for bulk filling.

- Work in lifts: For deeper gaps, fill halfway, let it cure, then top up. The tube helps place foam, but expansion physics still apply.

- Seal for later: When you’re done, leave the used tube on the can. Swap in a fresh one next time.

- Safety basics: Nitrile gloves, eye protection, and ventilation. Overspray on skin is a pain; cured foam doesn’t come off easily.

How They Compare

Compared to the single straw included with most foam cans, having a pack of ten is transformative for workflow. You don’t feel compelled to force a clogged applicator to limp along. Against “universal” straw kits with multiple adapters, this set is simpler and, in my experience, more reliable for standard cans—no stack of fittings to manage, no mystery tolerances. Versus a foam gun system, these won’t match the precision or long-term economy of a well-maintained gun, but they win on low cost and zero maintenance for occasional DIYers.

Value

Without getting into specific pricing, the math makes sense if you:

- Tackle several small sealing tasks over weeks.

- Frequently find yourself wasting half a can due to a clogged straw.

- Share a can between people or stations where cross-contamination and timing make a single straw impractical.

Ten tubes will carry most homeowners through multiple projects. Pros doing daily foam work should still consider a gun system, but even then, keeping a pack like this around for one-off straw cans isn’t a bad idea.

The Bottom Line

These clear replacement foam nozzles do exactly what they’re supposed to do: fit securely, deliver a predictable bead, and let you keep working by swapping a clogged straw in seconds. The transparent body is a subtle but real upgrade over opaque straws, and the 18.5 cm length strikes a good balance between reach and control. They won’t replace a pro gun for precision or reusability, and they’re not a magic wand for deep cavities, but for everyday gap-filling with DIY cans, they remove a lot of small frustrations.

Recommendation: I recommend this set for homeowners, DIYers, and anyone who uses straw-dispense foam intermittently. The convenience of clean, disposable tubes, solid fit on standard cans, and the ability to preserve partially used cans outweigh the minor limitations. If you’re outfitting a pro crew or require ultra-fine flow control daily, step up to a foam gun. For everyone else, keep a pack of these in the toolbox—you’ll use them more than you think.

Project Ideas

Business

Rapid Winterization Handyman Service

Offer a seasonal service for homeowners and landlords that uses can foam with fresh replacement nozzles for precise gap-filling around windows, pipes, and exterior penetrations. Market fast, affordable call-outs and document before/after photos to build recurring clients.

DIY Insulation & Repair Kits

Package small DIY kits that include 1–4 foam cans, multiple clear replacement tubes, gloves, and instructions for common tasks (window sealing, pipe insulation, small hole repair). Sell online to renters and DIYers who want an easy, mess-minimized option.

Prop & Set Supplies for Makers

Create and sell curated bundles of spray foam cans plus high-quality replacement tubes and craft-oriented guides for prop builders and cosplayers. Offer tiered bundles (starter, advanced) and digital tutorials or workshops to increase per-customer revenue.

Landlord Preventive Maintenance Subscription

Offer a subscription service to property managers that performs quarterly checks and targeted foam sealing with new replacement tubes to prevent drafts, pest entry, and heat loss. Provide maintenance logs and seasonal scheduling to reduce long-term repair costs for clients.

Creative

Precision Window & Door Restoration

Use the replacement nozzle to apply low-expansion spray foam into old window and door jamb gaps, sealing drafts without overspill. After curing, trim flush with a utility knife, sand smooth, and finish with wood filler and paint to preserve the historic look while adding insulation.

Custom Anti‑Rattle Bumpers

Form small foam pads by squirting controlled beads into disposable molds (bottle caps, silicon molds) using the clear nozzle. Once cured, trim and adhere the pads to cabinet doors, automotive panels, or shelving to eliminate vibration and create subtle protective bumpers.

Miniature Terrain Planters & Sculptures

Build layered tabletop landscapes and planter cores by extruding foam with the precision tube to create contours and overhangs. Carve and texture the cured foam, seal with a primer, waterproof with epoxy or acrylic sealer, then paint and add soil pockets for succulents or air plants.

Cosplay Armor & Prop Detailing

Use the replacement nozzle for fine control when adding raised details, ridges, or organic textures to base armor pieces. After curing, carve and sand the foam details, then coat with flexible sealers and paints. The clear tube gives consistent bead size for repeatable ornamentation.