Features

- Micrograin solid carbide construction

- Precision ground cutting edges for a fine finish

- Designed for improved edge retention

- Provides rigidity for longer tool life

- Suitable for cutting V-grooves and surface forming in various materials

Specifications

| Model Number | 85284MC |

| Order Number | 2610048209 |

| Shank (In) | 1/4 |

| Diameter (D) (In) | 1/4 |

| Radius (R1) (In) | |

| Pack Quantity | 1 |

| Material | Micrograin solid carbide |

Related Tools

Related Articles

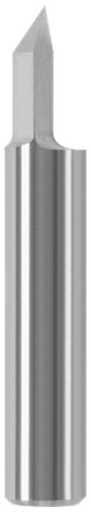

Solid carbide V-groove router bit intended for cutting V-shaped grooves and surface forming. Made from micrograin solid carbide and precision ground to provide a fine finish, with design emphasis on rigidity and edge retention for extended life.

Bosch 1/4 In. x 1/4 In. Solid Carbide V-Groove Router Bit Review

A small V-bit that punches above its weight

A simple V‑groove bit can do a lot more than letter a board. Over the past few weeks I put the Bosch V‑groove bit (1/4-inch shank, 1/4-inch diameter) through the kinds of tasks I reach for a V‑bit for most: sign lettering, crisp shadow lines on casework, decorative chamfers on drawer fronts, and a few inlay experiments. It’s a compact cutter, but it carries itself like a more substantial tool where it matters—at the cutting edge.

Build and geometry

This bit is a solid carbide cutter made from micrograin stock and it’s precision ground. You notice that immediately under light: the flutes are clean and even, and the tip is sharp with no visible flats or chipping right out of the package. There’s no pilot bearing, as you’d expect from a V‑groove profile, so you’ll be routing against a fence, template, or using a CNC.

With a 1/4-inch shank and a small overall diameter, it’s naturally a fit for palm/trim routers and benchtop CNCs. The smaller mass and compact length help keep chatter down in lighter-duty machines. The tradeoff is that you aren’t going deep—the geometry and diameter are intended for fine V‑grooves, lettering, and surface details rather than deep, wide V‑carves.

Worth noting: the included angle isn’t specified. In practice, it behaves like a fairly narrow V suited to detail work. If you require a specific 60° or 90° profile for V‑carving workflows, you’ll want to confirm with a test cut and calibrate your toolpaths accordingly.

Setup and compatibility

I used the bit in a compact palm router and a small desktop CNC. Collet fit was snug with no visible runout. In the palm router, the bit balances well—no extra vibration at the speeds typical for trim routers.

- Shank: 1/4 inch

- Diameter: 1/4 inch

- Material: micrograin solid carbide

- Pack: single bit

Because it has no bearing, I had best results with a guide bushing and template for hand routing, or by running the edge of the base against a fence. On the CNC, zeroing to the surface and running a quick calibration carve ensured text width matched expectations.

Cutting performance: hand routing

On a cedar sign blank, the bit produced clean V‑grooves with crisp shoulders and minimal fuzz. In pine, I got a touch of fuzzing on the earlywood, which brushed away easily; slowing down the RPM a notch reduced it further. In maple and oak, the cut quality stood out: edges were sharp, bottoms were clean, and there was no burn at moderate feed.

Control feels better than average with this cutter in a palm router. The small diameter and rigid carbide combine for a cut that “pulls” straight rather than skating. With a light touch, the tip traces layout lines predictably, which makes freehand accents and small flourishes less nerve‑wracking.

Depth per pass is where restraint pays off. I kept cuts to about 1/16 inch in hardwoods and 3/32 to 1/8 inch in softwoods and MDF. Pushing deeper increases heat at the tip; keeping passes shallow maintains edge life and surface finish.

What worked for me in a palm router:

- Speed: mid to high (roughly 20,000–24,000 RPM feel)

- Feed: steady hand pressure; don’t dwell in one spot

- Pass depth: 1/16 inch in hardwoods, up to 1/8 inch in softer stock

- Dust control: essential—V‑grooves create fine dust that hides the cut line

Cutting performance: CNC

On a benchtop CNC, the bit excels at small text and decorative lines. Micrograin carbide plus a sharp grind produces repeatable kerf width, which matters when you’re chasing consistent stroke weight across a sign. The tip stayed true through multiple runs in MDF and maple without visible degradation.

For small text (3/8 inch tall), I used shallow passes and a moderate spindle speed. The bit tolerated faster feeds in MDF, but in dense hardwoods, a conservative approach paid off in cleaner corners and less risk of tip heat. If your CAM expects a specific V‑angle, run a test tile first and fine‑tune tool definitions to match the profile you observe.

What worked for me on the CNC:

- Spindle speed: mid range for your machine; avoid max RPM in resinous woods

- Feed: light to moderate; prioritize finish over cycle time for small text

- Passes: multiple shallow passes; add a spring pass for glassy edges

Material-by-material results

- Softwoods (pine, cedar): Very good. Occasional fuzzing in earlywood that knocks off with a brass brush or light sanding. Minimal tearout when feeding with the grain.

- Hardwoods (maple, oak, walnut): Excellent. Crisp shoulders, clean V apex. Stick to shallow passes to avoid heat and preserve the tip.

- Plywood: Good for decorative scoring and shadow lines; glue lines can be abrasive. Expect a slightly darker cut line in some veneers.

- MDF: Very good finish with a near-polished groove; create strong dust extraction and consider a sealing coat after carving to harden fibers if painting.

- Plastics (acrylic): Usable with care. Lower RPM, higher feed, and shallow passes reduced melting. The small tip is unforgiving in overheated acrylic, so test first.

Edge retention and durability

Edge life has been strong for a small V‑bit. After multiple signs and a mix of chamfering and line work in hardwoods and MDF, the bit still leaves a bright surface without fuzz or torn grain. Micrograin carbide tends to hold a keener edge, and that’s consistent with what I saw here. As with any solid carbide, it’s brittle—treat drops and accidental clamps as game over. Store it in a dedicated holder.

Heat is the enemy. If you notice the cut darkening or a sweet smell in resinous softwoods, lighten up your pass depth, speed up the feed slightly, or drop RPM. That approach kept the edge fresh and avoided polishing the tip.

Where it shines

- Lettering and sign work where line consistency and crisp shoulders are the goal

- Decorative V‑grooves and shadow lines on cabinet doors and drawer fronts

- Breaking edges with a subtle, V‑profile chamfer rather than a flat 45°

- Template-guided accents with a palm router

- Small‑format CNCs carving detail where a larger V‑bit feels bulky

Limitations to consider

- Depth and width: With a 1/4-inch diameter, this is for fine detail, not deep, wide V‑carves.

- Unspecified V‑angle: If your workflow requires an exact included angle, you’ll need to calibrate. A quick test grid solves it but adds a step.

- No bearing: Not a flaw, just a reminder—you’ll need a fence, template, or CNC for guided cuts.

- Brittle by nature: Solid carbide is tough at the edge but doesn’t like impact. Treat it gently.

Tips for best results

- Make shallow, multiple passes—especially in hardwoods.

- Use sharp pencils or light scribe lines; the tip will track predictably along clean layout.

- For painted signs, seal MDF or softwoods after carving; the grooves finish cleaner with less swelling.

- Keep your router base slick and stable. A larger sub‑base plate helps maintain control over narrow stock.

- On a CNC, run a verification tile to match your CAM’s V‑bit angle to the actual profile.

Who it’s for

If you regularly do small lettering, decorative grooves, or want a crisp V‑chamfer on furniture parts, this bit fits neatly into a trim router kit or CNC rack. Woodworkers who favor handheld detailing will appreciate the control and finish. If your projects call for deep V‑carving or wide sign text in thick slabs, you’ll want a larger‑diameter V‑bit alongside this one.

Recommendation

I recommend this Bosch V‑groove bit. It’s a sharp, rigid, micrograin carbide cutter that delivers clean, predictable results in the kinds of fine detail work that a small V‑bit is meant to handle. Cut quality is consistently high across common shop materials, edge life has been strong with sensible feeds and shallow passes, and the 1/4‑inch shank makes it a natural match for palm routers and small CNCs. The only real caveat is the lack of a clearly stated included angle; build a quick test card and you’ll be set. For sign makers, furniture builders adding decorative lines, and anyone who wants crisp, controlled V‑grooves from a compact bit, it’s a dependable choice.

Project Ideas

Business

Custom V-Carved Signage Studio

Offer premium house numbers, shop logos, and wayfinding signs in hardwood, cedar, or HDU foam. V-carving produces elegant letterforms and crisp serifs that paint cleanly. Upsell with gilded grooves, color fills, and outdoor finishes; batch efficiently with jigs and CNC.

QR Menu and Smart Plaque Service

Produce durable QR plaques for restaurants, rentals, galleries, and events by V-carving the code matrix into wood or acrylic, then filling with contrasting paint/resin. The sharp V edges enhance scan reliability and look upscale versus printed decals.

Personalized Boards & Kitchenware

Sell monogrammed cutting/charcuterie boards, knife racks, and utensil rests with V-carved names, coordinates, or recipes. The V-bit yields sharp, food-safe engravings that don’t fuzz out like round-nose cuts. Offer gift packaging and rapid turnaround.

Cabinet & Interior Trim Detailing

Provide on-site or shop-based V-groove detailing for cabinet doors, wall panels, and beaded face frames. Add faux panel lines, fluting, or bead-and-shadow lines quickly with consistent depth, elevating builder-grade installs at high margins.

Wedding and Event Decor Packages

Bundle V-carved seating charts, table numbers, bar menus, and welcome signs in coordinated fonts and finishes. Offer rush service and rental frames/stands; the clean V-groove lettering photographs well and survives handling better than vinyl.

Creative

V-Carved Topographic Map Art

Use the V-groove bit to carve contour lines of a favorite mountain, lake, or city onto hardwood or MDF. The bit’s crisp V profile makes the linework clean and legible at varying depths, creating a striking relief map. Stain or paint different elevation bands, then oil for contrast.

Geometric Faceted Wall Tiles

Route intersecting V-grooves across square or hex tiles to create prism-like facets. Arrange tiles into a modular wall installation with alternating grain directions or colors. The consistent 90° V cuts catch light beautifully and add depth without complex 3D carving.

Resin-Inlay Coasters

V-carve patterns, monograms, or botanical line art into hardwood coasters. Flood the grooves with tinted epoxy, sand flush, and finish. The V profile locks the resin mechanically and yields crisp, high-contrast details that resist wear.

Celtic Knot Trivets

Create intertwined knotwork by V-carving continuous paths into thick bamboo or maple blanks. The V-grooves add shadow and definition while maintaining strength. Add a chamfered edge pass for a refined, heat-ready trivet.

Secret Message Puzzle Box

Design a small sliding-lid box with V-carved cipher strips or puzzle patterns on the lid and sides. The sharp grooves guide sliding components and conceal alignment marks; when aligned, the V-carved message reveals itself.