Features

- 3/4-inch cutting diameter

- 25/32-inch cutter length

- 2-inch overall length

- Carbide-tipped cutting edge

- 1/4-inch shank diameter

- Straight shank style

- Two flutes

- Universal compatibility

Specifications

| Cutting Diameter | 3/4 in |

| Cutter Length | 25/32 in |

| Cutting Edge Length | 25/32 in |

| Overall Length | 2 in |

| Shank Diameter | 1/4 in |

| Shank Style | Straight |

| Material | Carbide-tipped |

| Number Of Flutes | 2 |

| Bit Style | Straight |

| Router Type | Straight |

| Package Quantity | 1 |

| Product Weight | 6.7 oz |

| Package Dimensions | 4 x 1.5 x 1.25 inches |

Related Tools

Related Articles

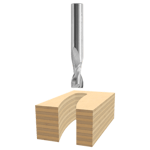

A straight carbide-tipped router bit with a 3/4-inch cutting diameter. Designed for general routing tasks (for example, chamfering and mortising), it has a 1/4-inch straight shank and two flutes for typical woodworking applications.

Skil Straight Carbide Router Bit, 3/4 in Review

Why I reached for this bit

I pull a 3/4-inch straight bit when I’m cutting clean dados for shelves, sizing mortises in furniture parts, or hogging out pockets before a pattern bit takes over. The Skil 3/4-inch straight bit slots into that role with a simple spec sheet: carbide-tipped, two flutes, 1/4-inch shank, 25/32-inch cutter length, and a compact 2-inch overall length. On paper, it’s a general-purpose workhorse. In practice, it’s a capable shop companion with a few caveats that are worth understanding before you push it hard.

Setup and compatibility

A 1/4-inch shank on a 3/4-inch cutter is convenient because it fits almost any router that accepts a 1/4-inch collet—from trim routers to mid-size fixed and plunge bases. I tested it in both a compact trim router and a full-size plunge router. While the bit technically fits a trim router, the mass of a 3/4-inch head is better managed by a heavier, more powerful motor and base. The full-size router gave steadier results, less chatter, and more confidence during wider passes.

Shank preparation and collet care matter here. I cleaned the shank and the collet, seated it with a full 3/4-inch of engagement, and checked for runout. The bit ran true. For a cutter this wide on a slender shank, that setup diligence pays off in cut quality and tool life.

As for speed, I kept it in the mid range recommended for larger bits—slower than you’d spin a 1/4-inch trim bit. Start conservatively and follow your router’s guidance. Pair that with sensible pass depth, and the bit behaves predictably.

Cut quality and accuracy

Right out of the package, the bit cut a clean, flat-bottomed dado in poplar and birch plywood with crisp walls and minimal fuzz. Using a straightedge fence and light pressure, my first 3/8-inch-deep pass was surprisingly smooth. The measured kerf was within a couple thousandths of 0.750 inch, which is what I hope for in a 3/4-inch straight cutter. If you build with solid 3/4-inch stock or want dead-on 3/4-inch dados, that accuracy is handy.

Two notes on plywood:

- Most “3/4-inch” plywood is undersized (often around 23/32). This bit will cut a true 3/4-inch slot, so you’ll need to adjust your layout to get a snug fit—either use two fence positions or shim a guide bushing to sneak up on the final width.

- To keep veneer tear-out at bay, I like to score the first 1/32 inch with a light climb pass (carefully and with both hands on the router), then follow with a standard pass. Backing up the exit side with a sacrificial strip also helps.

In softwoods and plywood, the two-flute geometry leaves a respectable surface. It isn’t as silky as a finishing spiral, but for joinery it’s plenty clean. In dense hardwoods like maple, I saw more risk of burn marks if I hesitated or took too heavy a bite. The remedy was simple: reduce depth of cut, keep the feed rate steady, and clean the edges if pitch builds up.

Performance in different materials

- Pine and fir: Very smooth cuts, little resistance. I took 3/16-inch passes without complaint and could push to 1/4 inch when clearing a wide pocket with multiple overlapping passes.

- Birch plywood: Clean walls, slight fuzz on the face veneer at exit if fed too aggressively. Scoring pass fixed it.

- Maple and white oak: Best results came from 1/8 to 3/16-inch passes with a deliberate, steady feed. The bit stayed on track, but any lingering in place quickly telegraphed as burnishing.

- MDF: Effective but harder on edges (MDF’s abrasives accelerate wear). Keep pass depth conservative and clean the bit more often.

Durability and edge life

This is a carbide-tipped bit, not a solid carbide spiral. That’s exactly what I expect in a general-purpose straight bit, and the edge life tracks with that expectation. After a handful of plywood projects and a couple of dados in maple, I saw the usual signs of wear: faint burn marks if I paused, and slightly more sanding needed on the sidewalls. A quick cleaning to remove resin, and the cut quality returned to “good enough for joinery” territory. After more maple, the edge began to show its limits with a little micro-chipping—still usable, but it reinforced the idea that this bit shines as a shop staple, not a production cutter for hours of hard hardwood routing.

If you work mostly in hardwoods or MDF, plan on more frequent cleaning and eventual replacement sooner than you would with a premium spiral. If you’re a hobbyist cutting occasional dados and mortises in softwoods and ply, the edge life is entirely reasonable.

Maintenance tips:

- Clean pitch with a non-caustic blade/bit cleaner rather than scraping.

- Avoid overheating; take multiple light passes.

- Store the bit so the carbide doesn’t knock around with others.

Handling and limitations

The compact 2-inch overall length is a double-edged sword. It reduces leverage and helps with stability, but it limits reach. For shallow dados, grooves, and surface mortises, it’s ideal. For deep mortises, a longer shank or a smaller-diameter bit is a better call.

Because it’s a straight bit, chip evacuation is adequate but not exceptional. In deep grooves, chips want to pack if the feed rate drops. Clearing the channel between passes and maintaining a consistent push keeps the cut from heating up.

A word on plunging: Straight bits vary in how well they plunge. I prefer a ramp-in approach with the router’s depth stop or a series of increasingly deeper passes when starting inside the workpiece. It’s gentler on the edges and reduces chatter at the start of the cut.

Where it excels

- Cabinet dados in solid stock: One pass per depth increment, excellent width control.

- Shelf grooves and stopped dados with a plunge base: Crisp shoulders, flat bottoms.

- Mortise sizing: After roughing with a smaller bit, this bit cleans to final width reliably.

- Pocketing before template routing: Quickly removes bulk waste to save wear on a flush-trim bit.

Where I’d reach for something else

- Veneered plywood that needs a show-surface edge: A spiral downcut will give cleaner top edges.

- Deep mortises in hardwood: A smaller-diameter upcut spiral—and a stiffer shank—clears chips and reduces heat.

- Heavy-duty production: A solid carbide spiral offers longer life and better heat management under constant use.

Practical guidance for best results

- Pass depth: 1/8 to 3/16 inch is the sweet spot. Avoid full-width, full-depth cuts.

- Speed: Run slower than small-diameter bits; let the cutter and router stay cool.

- Support: Use a fence, guide bushing with a template, or a tight dovetail-style jig to keep the router from wandering.

- Plywood: Score a shallow first pass, back up the exit edge, and set expectations for veneer behavior.

- Fit: Remember that 25/32-inch cutter length gives you a hair more than 3/4-inch depth capacity, which is useful for standard shelf dados.

Bottom line

The Skil 3/4-inch straight bit does what a general-purpose straight bit should: it cuts to size, leaves flat bottoms, and stays controllable in typical shop materials when used with sensible technique. Its 1/4-inch shank makes it broadly compatible and easy to grab for routers of all sizes, though it feels most at home in a mid-size or full-size router where the larger cutter diameter is better supported. Edge life is fair for a carbide-tipped, two-flute straight bit—enough for steady hobby use and light shop duty, with predictable wear if you push into dense hardwoods or lots of MDF.

Recommendation: I recommend this bit for woodworkers who need an accurate, budget-friendly 3/4-inch straight cutter for dados, grooves, and shallow mortising in softwoods and plywood, and occasional use in hardwoods. It’s a solid choice as a utility bit in a general-purpose kit. If your work leans heavily on hardwood joinery or production routing, invest in a premium spiral for longer life and cleaner edges; keep this Skil in the drawer for everyday tasks and roughing work.

Project Ideas

Business

Custom Workbench Tops (3/4 Dog-Hole Grids)

Offer precision-drilled bench tops and MFT-style panels with 3/4-inch hole grids, chamfered edges, and finish options. Target makers, contractors, and DIYers who want ready-to-use clamping surfaces without CNC lead times.

Modular Cross-Lap Wine Rack Kits

Produce flat-pack wine rack kits using 3/4-inch-wide cross-lap joinery in hardwood or quality plywood. Sell in standard sizes and stains, with branding burned in and optional expansion packs for larger cell counts.

Premium Magnetic Knife & Spice Bars

Rout hidden 3/4-inch magnet pockets in hardwood bars (walnut, maple, cherry) and offer custom lengths and engravings. Bundle with mounting hardware and premium finishes; wholesale to kitchen boutiques and Etsy/online.

Resin Pixel Art Panels & Coasters

Create wall art and coaster sets by routing 3/4-inch square pockets and filling with colored resin or contrasting wood inlays. Sell themed sets (logos, gradients, map pixels), and offer corporate branding and gift packaging.

STEAM Marble-Run Boards for Schools

Manufacture durable classroom marble-run panels with routed 3/4-inch tracks and interchangeable add-ons. Market to schools and museums as hands-on physics kits, including lesson plans and replacement parts.

Creative

Cross-Lap Wine Rack

Batch out 3/4-inch-wide, half-depth slots in 3/4-inch boards with stop blocks, then interlock the slats to form a modular honeycomb wine rack. The straight, carbide-tipped bit leaves flat-bottomed laps for tight fits and clean glue surfaces.

Pixel Art Wall Panel

Route a grid of 3/4-inch square pockets 1/4–3/8 inch deep on a plywood or hardwood panel. Fill the pockets with contrasting wood tiles or tinted epoxy to create pixel-style art or geometric patterns; frame the panel for a gallery look.

Marble-Run Activity Board

Cut 3/4-inch-wide channels and pockets into a plywood panel to form paths, drops, and catch basins for marbles. Add thin hardwood rails or an acrylic cover to retain marbles, and mount the board for an interactive wall feature.

Magnetic Knife/Utensil Bar

From the back of a hardwood strip, rout 3/4-inch circular recesses for neodymium magnets using a simple circle template or guide bushing. Leave a thin face, epoxy in the magnets, and add keyhole slots for mounting.

MFT-Style Mini Work Surface

Plunge 3/4-inch dog holes in a precise grid into 3/4-inch MDF or Baltic birch to make a portable clamping/assembly board. Add a perimeter frame and a few custom bench dogs or holdfast accessories.