Features

- Turbo rim V-groove cutting profile for material removal and smoother cuts

- Compatible with small angle grinders (7/8 in arbor)

- Intended for cutting concrete and mortar

- Sold as a single blade

Specifications

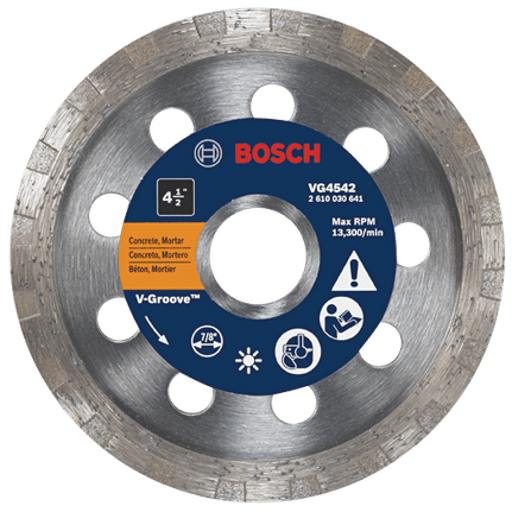

| Model Number | VG4542 |

| Diameter | 4-1/2 in |

| Arbor | 7/8 in |

| Cutting Depth | 1-1/4 in |

| Tool | Small angle grinder |

| Application | Concrete, mortar |

| Pack Quantity | 1 |

| Availability |

Related Tools

Related Articles

Turbo rim V-groove diamond blade sized for 4-1/2 in grinders. Intended for cutting concrete and mortar with a focus on producing smooth cuts. Supplied as a single blade and sized for use with a 7/8 in arbor on small angle grinders.

Bosch 4-1/2 in Turbo Rim V-Groove Diamond Blade for Smooth Cuts Review

What this blade is designed to do

Bosch’s V-groove diamond blade is a compact, 4-1/2 inch turbo-rim wheel built for small angle grinders with a 7/8-inch arbor. It’s aimed squarely at concrete and mortar work, prioritizing smoother cuts over the ragged edges you often get from aggressive segmented blades. In practice, that “smooth” claim matters for scoring slabs, trimming pavers, cleaning up mortar joints, and any situation where you want speed without excessive spalling on the surface.

With a 1-1/4 inch maximum cutting depth, it’s a jobsite-friendly size for quick tasks and detail work. You won’t be slicing through full-thickness block in one pass, but that’s expected for this diameter. The blade is sold individually, which suits pros and DIYers who want to try a specific profile without committing to a multi-pack.

Setup and compatibility

I ran the V-groove blade on a 4-1/2 inch variable-speed grinder with a standard flange and guard. The 7/8-inch arbor is a common fit for small grinders; if your machine uses a 5/8-11 threaded spindle, the flange typically centers 7/8-inch-bore wheels without fuss. Installation was straightforward, and the blade ran true with no initial wobble.

If you’re switching from a segmented rim, the turbo rim on this blade will look a bit more continuous and tighter in its pattern. That’s normal—it’s part of what gives it a cleaner cut face.

Cutting performance

I used the blade on:

- Scoring and cutting control lines in a cured concrete slab

- Trimming concrete pavers for a patio fit-up

- Chasing and widening mortar joints in a brick wall

- Light shaping on a small concrete stepping stone

On cured concrete, the blade bites quickly once you score a shallow first pass. It tracks predictably without wandering, which I attribute to the V-groove profile helping establish a path. On pavers, I needed two passes and a flip to complete cuts past the 1-1/4 inch depth. That’s standard for 60–70 mm pavers, and the blade handled the flip cut without chipping the face excessively.

Mortar joint work is where the turbo rim shines. It grinds and cuts with a controlled feel, removing material efficiently but not so aggressively that you overshoot. The cut face is visibly smoother than what I typically see with a segmented blade—less tearing on the arris and fewer microchips at the edge, especially if you start with a light scoring pass.

Speed is solid for its size. It’s not a demolition blade, and it doesn’t pretend to be. The balance leans toward cut quality over brute removal, which is exactly what I want in a finishing or layout blade.

Cut quality and edge finish

Surface spalling on the top edge was minimal when I:

- Made an initial shallow score (1/8 to 1/4 inch)

- Let the blade reach full speed before contacting the work

- Kept a consistent feed rate without side-loading

The turbo rim’s continuous contact seems to reduce chatter that causes chips to pop at the surface. On the underside of deeper cuts, I still saw some breakout (again, normal), but it was easy to manage by flipping the work after a score and finishing from the opposite side.

For visible cuts—like trimming pavers that land against edging—the finish is neat enough that I didn’t feel the need to dress the edges.

Heat management and dust

I ran the blade dry with a dust shroud and vac. Heat build-up was manageable. In longer continuous cuts, the rim got warm but didn’t glaze; a quick relief pass off the material brought the shine down and kept the cut biting. As always, avoid forcing the tool—let the diamonds work.

If you have the option to lightly mist the work area (and you’re working in a situation where water is appropriate and safe for your grinder), it will further reduce dust and keep the cut cool. Dry use is fine with proper PPE and vacuum extraction.

Vibration, noise, and feel

Vibration was low for a 4-1/2 inch blade. The grinder remained stable, and the blade didn’t sing or whine excessively at speed. In concrete, it felt composed; in mortar, it felt almost like a hybrid between a cutting wheel and a light grinder—fast enough to be efficient, controlled enough to keep you on line. There was no noticeable drop in performance due to balance issues or uneven wear during my sessions.

Durability and wear

After several dozen linear feet of cutting (mix of slab scoring, paver trimming, and joint work), wear on the rim was even, with no segment loss and no obvious hotspots. The V-groove profile didn’t round over prematurely. It’s not a marathon demolition blade, but for layout, finishing cuts, and general purpose hardscape tasks, the service life feels appropriate for its size and intent.

As always, your mileage varies with the aggregate hardness in your concrete, how aggressively you feed the cut, and whether you’re running dust control.

Limitations

- Cutting depth: At 1-1/4 inches, you’ll need to flip thicker pavers and block. That’s typical for this size, but worth noting if you routinely tackle 2-3 inch materials.

- Not a metal or tile blade: It’s built for concrete and mortar. You can nudge some masonry stone with it, but for porcelain or very hard natural stone, a different rim profile is better.

- Single blade packaging: Convenient for trying it out, though if you’re outfitting a crew, you may prefer multi-packs to manage consumables.

Best practices from use

- Score first: A shallow first pass dramatically improves cut quality and tracking.

- Don’t force it: Maintain RPMs and let the turbo rim work; pushing hard increases heat and surface spalling.

- Control dust: Use a shroud and vac or appropriate wet methods if allowed.

- Keep it straight: Any side pressure will degrade the edge finish and could shorten blade life.

- Respect the guard: The smaller diameter encourages deep angles—keep your guard aligned and your stance clear.

Who this blade suits

- Hardscape installers needing clean paver fits and on-site adjustments

- Remodelers chasing or widening mortar joints with controlled removal

- DIYers tackling patio, step, or small slab projects where neat edges matter

- Pros who prefer a smoother finish than segmented blades provide, without stepping up to a larger saw

If your work is mostly deep ripping of CMU or heavy demolition cuts, you’ll want a larger diameter segmented blade on a different tool. If your priority is clean, accurate cuts on concrete and mortar with a compact grinder, this blade hits the mark.

Value and availability

As a single blade purchase, it’s an easy add for a grinder kit. You’re paying for the turbo rim’s blend of speed and finish rather than brute segment height. Based on the cut quality and lifespan I observed, the value feels fair for anyone who prioritizes cleaner edges and predictable tracking.

Recommendation

I recommend the Bosch V-groove diamond blade for small angle grinder users who need clean, controlled cuts in concrete and mortar. It strikes a thoughtful balance: fast enough for practical jobsite work, refined enough to minimize spalling and rework. The 1-1/4 inch cutting depth is the natural ceiling of this diameter, so plan on flip cuts for thicker stock, but within that envelope it performs reliably, runs smoothly, and wears evenly. If your projects demand neat edges and accurate scoring more than raw demolition speed, this blade belongs in your kit.

Project Ideas

Business

Decorative Concrete Engraving Service

Offer on-site scoring of existing patios, driveways, and garage floors to mimic tile, stone, or parquet patterns. The V-groove profile yields clean, shadowed joints that can be stained for contrast. Upsell sealing and color antiquing.

Crack Chasing and Repair Prep

Provide crack-chasing services for residential slabs by opening cracks into controlled V-grooves to accept flexible sealants or polyurea. This improves adhesion and longevity of repairs; bundle with surface cleaning and re-sealing.

Custom Address and Logo Pavers

Produce and sell engraved address stones, pathway markers, and small business logo pavers. Cut V-groove graphics into precast blanks, then inlay with contrasting mortar or epoxy. Sell via local markets, Etsy, and contractor partners.

Safety Anti-Slip Step Grooving

Cut parallel V-grooves across outdoor concrete steps and pool decks to improve traction and channel water. Package as a quick retrofit for property managers and homeowners; add optional color-filled grooves for high visibility.

Low-Voltage Cable and Drainage Chase Cuts

Create neat V-groove channels in patios/paths to recess low-voltage lighting or irrigation sensor lines, then backfill with mortar for a flush finish. Offer micro-drainage grooves to redirect puddling on flat slabs.

Creative

Epoxy-Inlay Concrete Coasters

Cast small concrete coaster blanks, then use the V-groove blade to score geometric or wave patterns about 1/8–1/4 in wide up to 1-1/4 in deep. Fill the channels with colored epoxy or metallic powder-infused resin for contrast, sand flush, and seal. The V profile helps the inlay lock in mechanically.

Mandala Stepping Stones

Cut radiating V-grooves into round or square stepping stones to form mandala designs. Wash the grooves with pigmented grout or slurry, then seal. The turbo rim leaves clean shadow lines that pop visually in a garden path.

Address Stone With Metallic Accents

On a precast concrete plaque or paver, layout house numbers and cut V-groove outlines for each character. Inlay with brass rod, crushed glass, or colored mortar. Mount near the entrance for a custom, durable address marker.

Shadow-Line Planters

Score crisp horizontal and vertical V-grooves around plain concrete planters to create modern shadow lines and drainage accents. Alternate groove spacing and depth for a tiered visual effect without weakening the planter.

Concrete Lantern Blocks

On hollow concrete blocks, carve repeating V-groove patterns (chevrons, lattice, or waves) on the faces to create light-catching textures. Backlight with LED tea lights; the grooves create dramatic highlights and shadows.