Features

- 600 lb clamping capacity

- Two‑piece clutch lock

- 2.5 in throat depth

- Ergonomic quad‑lobe bi‑material handle

- 36 in maximum opening

- 0.25 in jaw width

- Limited lifetime warranty

Specifications

| Clamp Type | Bar |

| Clamping Strength (Lb.) | 600 |

| Duty Rating | Standard |

| Hand Tool Type | Clamp |

| Individual/Set | Individual |

| Material | Multi‑Surface |

| Maximum Opening (In.) | 36 in |

| Jaw Width (In.) | .25 in |

| Throat Depth (In.) | 2.5 in |

| Returnable | 90‑Day |

| Manufacturer Warranty | Limited Lifetime Warranty |

| Tools Product Type | Hand Tool |

| Upc/Gtin 13 | 0076174838305 |

| Store Sku | 1002793548 |

| Item Id / Model | 303121311 / DWHT83830 |

Related Tools

Related Articles

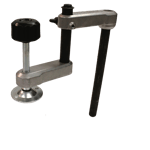

36-inch medium‑duty bar clamp rated for up to 600 lb of clamping force. Features a 2.5 in throat depth and a two‑piece clutch lock for secure holding. Equipped with an ergonomic quad‑lobe, bi‑material handle for improved grip. Suitable for general clamping tasks. Comes with a limited lifetime warranty.

DeWalt 36 in. 600 lb. Bar Clamp (2.5 in. throat depth) Review

Why I reached for this 36-inch clamp

Big glue-ups and long assemblies are where clamps earn their keep, and that’s exactly the niche this 36-inch bar clamp fills in my shop. It’s a medium-duty, clutch-style bar clamp with a 36-inch max opening and a 2.5-inch throat depth—enough reach for cabinet carcasses, wide panel glue-ups, and the occasional on-site door tweak. I’ve used it for edge-gluing boards into tabletops, holding face frames in place during pocket-screw assembly, and squaring up large boxes where shorter clamps just won’t span the distance.

From the first use, it felt like a dependable, no-drama tool: it moves easily, locks positively, and generates more than enough pressure for most woodworking tasks. But like any long bar clamp, it has limits, especially when you’re working near its full span. Here’s how it performed and where it fits in alongside pipe clamps and parallel-jaw heavy hitters.

Build and ergonomics

The bar is stout and the sliding head tracks without slop. There’s a hint of camber in the bar—nothing unusual on a 36-inch length—and the steel feels appropriately rigid for a “standard duty” rating. The clutch lock is a two-piece design that engages the bar’s serrations crisply; adjustments are quick with one hand and the head stays where I put it.

The handle deserves a mention. The quad-lobe, bi-material grip isn’t flashy, but it’s practical. I can get a full, comfortable grab with gloved or bare hands, and it’s grippy when dusted with glue squeeze-out. You won’t mistake it for a long T-handle when cranking down, yet it delivers respectable torque without chewing into your palm.

Weight is balanced toward the fixed jaw, which makes one-handed placement easier than I expected for a clamp this long. The jaw faces are flat and well-aligned out of the box. They haven’t marred pine, poplar, or birch plywood in my use, but for delicate surfaces I still throw a scrap caul between the jaw and the work.

Clamping performance

Rated at 600 lb of clamping force, this is solidly in the medium-duty camp. In practical terms, it’s plenty for:

- Edge-gluing 4/4 boards into panels

- Holding case parts in light assemblies

- Securing jigs, fences, and straightedges to sheet goods

- Light door or frame alignment work on site

The clutch mechanism lets me bring the sliding jaw into contact quickly; from there, the handle adds controlled pressure. Under typical loads (panel glue-ups and box assembly), the bar stays straight enough that I’m not fighting twist or losing alignment.

When you begin to push toward the top end of its length and force—think clamping across a full 36-inch span or cinching a door where you need to counter a warp—you’ll start to see the natural trade-off of this category: deflection. The bar can bow slightly as you crank down. That’s not a defect; it’s physics with standard-duty bars at their maximum reach.

Managing deflection at full span

Any 36-inch standard bar clamp will flex some when fully extended. With this model, the bow is moderate, and I’ve managed it with a few shop habits:

- Add cauls: A straight caul top and bottom helps distribute pressure and keeps assemblies flat.

- Oppose the clamps: Use two clamps facing opposite directions to counteract each other’s tendency to bow.

- Keep the span shorter when you can: If a 30-inch clamp will do, use it. A bar loaded at 80% of its length is stiffer than one at 100%.

- Don’t chase the last ounce of force: You rarely need to approach the rated capacity in woodworking glue-ups. Good fits and proper cauls reduce how hard you need to crank.

If you routinely clamp full-width doors or insist on perfectly parallel pressure with minimal flex, a pair of parallel-jaw clamps or pipe clamps with thicker bars will be a better fit. For general cabinet and furniture work, the 36-inch bar here has enough backbone as long as you use sensible techniques.

Throat depth and jaw profile

At 2.5 inches of throat depth, this clamp stays in the “general-purpose” lane. It reaches far enough for edge work, face frames, and most carcass assemblies, but it’s not meant for deep clamping into the center of large panels. The relatively slender jaw profile is helpful in tight assemblies and when sneaking in around hardware or protrusions. If your work often needs deeper reach, consider pairing these with a few deep-throat clamps.

Real-world use cases

- Panel glue-ups: Three or four of these spaced evenly produced flat, even pressure on 18- to 30-inch-wide panels. I add cauls on long boards to keep everything aligned.

- Casework: Handy for pulling cabinets square and holding backs in place for stapling or screwing. The bar length gives breathing room around a 24-inch carcass.

- Shop fixtures: Great for securing a straightedge when breaking down sheet goods, or pinning a jig to a benchtop without racking.

- Trim and site work: Long enough to pull a jamb into alignment or hold a door for light planing, though I wouldn’t rely on it alone for correcting heavy warps.

Speed and control

The clutch lock earns its keep. It slides quickly into position and bites cleanly. I appreciate that I don’t have to “fight” the mechanism under load—the head stays put unless I intentionally release the clutch. The handle turn is smooth, with enough travel to fine-tune pressure. This combination makes it easy to get from rough position to final pressure without fuss, which is exactly what I want in a bar clamp.

Durability and maintenance

After glue, dust, and the occasional knock to the floor, mine still runs smoothly. Keep the bar clean and dry, wipe off glue squeeze-out before it cures, and it will continue to engage reliably. The limited lifetime warranty is reassuring; clamps are simple tools, but jaws and clutch plates can wear with heavy use. It’s the kind of product you expect to buy once and keep for years with basic care.

Where it fits in a clamp lineup

- As a generalist: It’s a versatile 36-inch option that covers a lot of ground in a small shop or on site.

- Against pipe clamps: Pipe clamps are stiffer and more modular for extra-long spans, but heavier and less refined in feel. If you’re flattening big tops or fighting twist at full width, pipe clamps still rule.

- Against parallel-jaw clamps: Parallels deliver flatter, more even pressure with less bar flex, but they cost more and are bulkier. For everyday tasks, this bar clamp is lighter and quicker to deploy.

The sweet spot for this model is the woodworker who needs long reach occasionally but spends most of their time on medium-scale assemblies where speed and manageable weight matter.

Quibbles

- Full-span bowing is real: Manageable, but present. It’s the price of a standard-duty 36-inch bar.

- Limited throat depth: 2.5 inches covers most tasks, but deep clamping needs other tools.

- Slender jaws: Helpful in tight spots, but I rely on cauls for broader contact on wide glue-ups.

None of these are dealbreakers—they’re more about choosing the right tool for the job and understanding the compromises inherent to this clamp style.

Bottom line and recommendation

I recommend this 36-inch clamp as a reliable, medium-duty workhorse for woodworking and general shop use. It’s easy to position, comfortable to tighten, and strong enough for the kinds of tasks most of us tackle day to day—panel glue-ups, box assemblies, case alignment, and jig setup. The clutch mechanism and handle design make it quick and predictable, and the overall build inspires confidence. Just be aware of the natural limits: at its full 36-inch span, the bar can bow under high pressure. If your workflow often pushes clamps to max length with heavy force—flattening doors, correcting significant twist, or demanding near-parallel pressure—supplement it with pipe clamps or parallel-jaw clamps.

As part of a balanced clamp lineup, this one earns its spot. It’s a practical, easy-to-use tool with a sensible blend of strength, reach, and ergonomics, backed by a lifetime warranty. For most woodworkers and jobsite users, that combination makes it an easy recommendation.

Project Ideas

Business

Mobile Glue-Up and Repair Service

Offer on-site clamping and curing for loose chair joints, veneer delamination, split tabletops, and edge re-glues. The quick two-piece clutch lets you work efficiently in clients’ homes. Charge a call-out fee plus hourly rate and materials; upsell protective pads and finish touch-ups.

Panel Glue-Up Production

Provide edge-glued panels and tabletops for DIYers and small cabinet shops. Use racks of 36 in. bar clamps with top/bottom clamping and cauls for flat, tight glue lines. Price per square foot with add-ons for flattening, sanding, and delivery. Great for cutting board blanks, shelves, and door panels.

Custom Longboard/Skate Decks

Small-batch laminate decks using clamp-on molds—no press required. Offer custom shapes, wheelbase drilling, and graphics. Sell direct online and at local markets; market the hand-pressed construction and limited runs. The 600 lb clamping capacity per clamp ensures solid laminations.

Clamp Kit Rental for DIY Glue-Ups

Rent weekend glue-up kits: 36 in. bar clamps, cauls, wax paper, squares, and instructions. Ideal for apartment woodworkers who can’t justify owning many clamps. Tier pricing by number of clamps; require deposit and offer optional delivery/pickup.

Workshops and Content Monetization

Host classes on panel glue-ups, curved laminations, and veneer pressing, centered on proper clamp setup, pressure, and caul design. Record sessions for online courses and short-form content with affiliate links to tools. Revenue from ticket sales, sponsorships, and digital downloads.

Creative

Laminated Curved Wall Shelf

Rip thin hardwood strips, spread glue, and press them into a curved form using several 36 in. bar clamps and cauls. The 600 lb clamping capacity and two‑piece clutch let you dial in even pressure along the curve while the 2.5 in throat keeps pressure off the very edge, reducing denting. Once cured, sand and finish for a sculptural floating shelf.

Butcher Block Cutting Board

Glue up alternating wood strips into a thick cutting board. Lay boards on edge, apply glue, and use multiple 36 in. clamps top and bottom to prevent bowing. The ergonomic handle helps with repeated tightening, and the strong clamping force ensures tight glue lines. Add juice groove and feet after flattening.

Veneer Art Panel Press

Create marquetry or veneer art by pressing veneer to a plywood/MDF substrate with wax paper and cauls. Space bar clamps across the panel; the secure clutch lock keeps set pressure while glue cures. The shallow 0.25 in jaw pads benefit from wide cauls for even pressure distribution across the face.

Custom Longboard Skateboard

Laminate 6–8 thin maple plies over a simple press mold. At ~32–36 in length, the board fits the clamp’s opening. Use a line of bar clamps along the mold to achieve a tight bond; the 600 lb capacity per clamp helps eliminate voids. Shape, sand, and add trucks and grip tape.

Live-Edge Crack Pull and Bowtie Inlay

Close a split in a live-edge slab by using opposing cauls and the bar clamp to pull the crack tight while epoxy sets. Add bowtie inlays after cure. The 2.5 in throat depth allows clamping slightly inboard without marring the edge; protect surfaces with pads.