Features

- Durable construction

- 3.5 TPI tooth design

- All Access Slots for easier plug removal

- Increased visibility for accurate placement

- Thermoset Coating for reduced friction

- Lifetime Tooth Break Warranty

- Made in the USA

- Suitable for various materials including metals and wood

Specifications

| Size | 4-3/8" |

| Cutting Depth | 1-5/8" |

| Weight | 0.996 lb |

| Length | 1.875 in |

| Height | 4.375 in |

| Width | 4.375 in |

| Shank Size | 3/8 in |

| Rpm For Stainless Steel | 40 |

| Rpm For Mild Steel | 80 |

| Rpm For Cast Iron | 50 |

| Rpm For Aluminum | 120 |

| Packaging | Shrink Wrap |

Related Tools

Related Articles

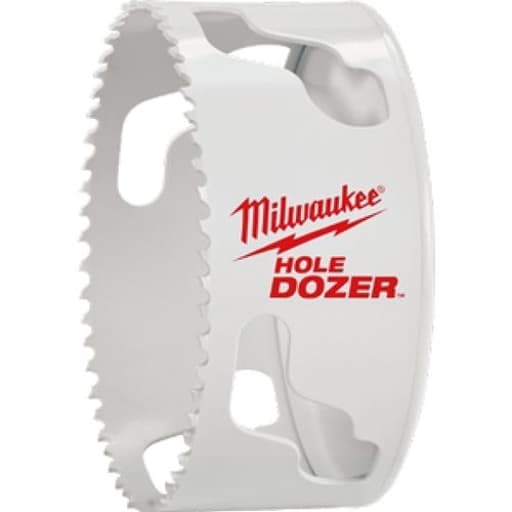

The Hole Dozer Bi-Metal Hole Saw features a 3.5 TPI tooth design for extended durability in metal applications. It is designed for general-purpose use and comes with a warranty for tooth breakage.

Milwaukee Hole Dozer Bi-Metal Hole Saw Review

There’s a certain satisfaction that comes from using a tool that performs exactly as it should, and the Milwaukee Hole Dozer Bi-Metal Hole Saw embodies this experience perfectly. As someone who frequently works with various materials, I’ve found the Hole Dozer to be an indispensable addition to my toolkit. Let me walk you through my experience using this versatile hole saw.

The first thing that struck me about the Hole Dozer is its robust construction. The bi-metal design, combined with the 3.5 TPI (teeth per inch) tooth pattern, promises durability and longevity. And it delivers on this promise. I’ve put this tool through its paces, cutting through everything from dense hardwoods to mild steel, and it has consistently performed without showing significant signs of wear.

One of the standout features of the Hole Dozer is its All Access Slots. These slots make plug removal a breeze, which, if you’ve ever used a hole saw, you’ll know can be a frustrating and time-consuming task. With other hole saws, I often find myself wrestling to remove plugs, but the design of the Hole Dozer makes it a smooth and hassle-free process. This small but thoughtful feature significantly speeds up my workflow, especially on larger projects where time is of the essence.

Another aspect that enhances the user experience is the increased visibility for accurate placement. The design allows for a clear view of the cutting area, ensuring that I can start the hole precisely where I need it. This feature is particularly useful when working on intricate projects where accuracy is paramount.

The Hole Dozer isn't just about cutting efficiency; it also focuses on reducing friction. The Thermoset Coating on the saw reduces heat build-up, which is crucial when working with tougher materials. I’ve had instances where other hole saws overheated and dulled quickly, but the Hole Dozer maintains its sharpness, even after extensive use. This not only prolongs the life of the tool but also ensures consistent performance throughout its lifespan.

Switching out different sizes of the Hole Dozer is seamless, thanks to its easy-to-install design. The tool is available in various sizes, but the 4-3/8" model I primarily used offers a cutting depth of 1-5/8", which is more than adequate for most of my projects. The shank size is 3/8", fitting standard drills without any issues.

When it comes to cutting performance, the Hole Dozer excels across a range of materials. Whether it's wood, drywall, or metals like mild steel and aluminum, this hole saw cuts through with ease. For instance, while installing electrical circuits, the Hole Dozer effortlessly bored through multi-layered walls comprising wood and sheetrock. The cutting was clean, with minimal splintering or chipping on the backside, which is often a challenge with other tools.

However, it's important to note that while the Hole Dozer is highly effective on wood and metal, it isn't designed for stone, stucco, or concrete. I attempted to use it on stucco once, and it struggled significantly. For such materials, Milwaukee’s carbide-tipped hole saws are a better choice. This limitation is something to keep in mind if your projects frequently involve tougher substrates.

Durability is another area where the Hole Dozer shines. The lifetime tooth break warranty underscores the confidence Milwaukee has in this product. This warranty provides peace of mind, knowing that the tool is designed to withstand the rigors of heavy-duty use. In my experience, the teeth remained sharp and effective even after numerous cuts, which is a testament to its build quality.

On a practical level, the Hole Dozer is relatively lightweight at just under a pound, making it easy to handle during extended use. The balance between weight and performance is well-executed, ensuring that the tool is neither too heavy to cause fatigue nor too light to compromise stability during cutting tasks.

In terms of speed, the Hole Dozer does not disappoint. For instance, when drilling through 1-inch hardwood flooring, the tool maintained a steady pace without bogging down. The recommended RPMs for different materials, such as 40 RPM for stainless steel and 120 RPM for aluminum, are useful guidelines to achieve optimal performance and avoid potential damage to the tool or workpiece.

The visual appeal of the Hole Dozer might not be a primary concern for many, but I appreciate the clean, professional finish of Milwaukee’s tools. This attention to detail is indicative of the brand’s overall commitment to quality.

In summary, the Milwaukee Hole Dozer Bi-Metal Hole Saw is a high-performing, reliable tool that excels in a variety of applications. Its durable construction, ease of use, and thoughtful design features make it a valuable addition to any professional or DIY enthusiast's toolkit. While it does have limitations with certain materials like stone or concrete, its performance on wood, metal, and other common materials is outstanding.

Would I recommend the Hole Dozer? Absolutely. Its combination of durability, efficiency, and user-friendly features make it a worthwhile investment for anyone needing a versatile and reliable hole saw. Whether you’re a professional tradesperson or a weekend warrior, the Hole Dozer stands out as a tool that delivers on its promises, making your projects easier and more efficient.

Project Ideas

Business

Custom Metal Fabrication Service

Offer a service to cut precise circular holes in metal sheets for clients who need specific sizes for various projects, including HVAC, plumbing, and electrical installations.

Artisan Home Decor

Create and sell handcrafted home decor items like clocks, light fixtures, and shelving units. Market them as unique, handmade pieces to attract customers looking for bespoke home accessories.

Garden Accessories Shop

Establish a business specializing in custom garden accessories, including planters with custom drainage holes and metal garden art. Offer personalized designs to cater to gardening enthusiasts.

Event Decoration Rentals

Rent out custom-made decorative items like unique light fixtures, table centerpieces, and wall art for special events such as weddings and corporate parties. Use the hole saw to create intricate designs.

DIY Workshop Classes

Host workshops teaching people how to use the Hole Dozer Bi-Metal Hole Saw to create various DIY projects. Charge a fee for classes and provide materials and guidance for participants to take home their creations.

Creative

Custom Metal Clock Faces

Use the Hole Dozer Bi-Metal Hole Saw to cut precise circular openings in metal sheets to create unique clock faces. Decorate with paint or engravings for personalized designs.

DIY Industrial Shelving

Create industrial-style shelves by cutting circular holes in metal or wooden boards for pipe fittings. Assemble with pipes for a sturdy and stylish look.

Garden Planter Holes

Drill holes in metal or wooden containers to create drainage for garden planters. Customize the size and number of holes to suit different plants' needs.

Custom Light Fixtures

Design and create custom light fixtures by cutting holes in metal or plastic sheets. These can serve as unique lamp shades or bases that fit standard light bulbs.

Musical Instrument Parts

Craft parts for DIY musical instruments, such as drum shells or speaker ports, by precisely cutting circular sections in wood or metal.