Features

- EXCELLENT FUNCTIONALITY:Metal roofing has superior weather resistance and can withstand extreme weather conditions such as strong winds, heavy rain, ice and snow. After proper installation, metal roof panels are not easily blown by wind and have good drainage properties, effectively reducing the burden of snow or ice on the roof

- HIGH QUALITY MATERIALS:Metal roofing made from high-quality galvanized steel provides excellent waterproofing and sun protection. Due to its lightweight design, durability, energy efficiency and effective waterproofing, reusable metal roofing panels have gained popularity in modern construction

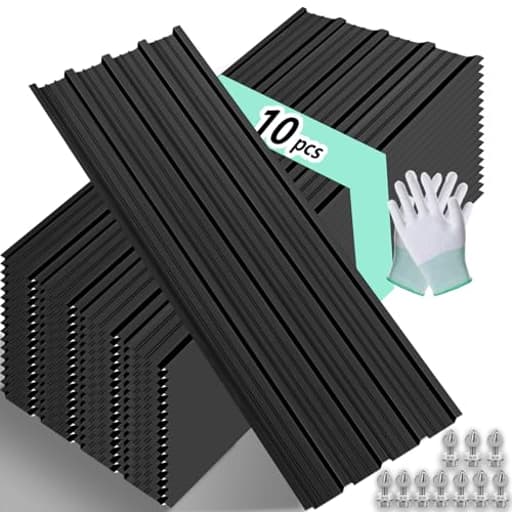

- EASY TO INSTALL :Metal roofing sheets come in packs of 10,Thickness 0.01inch/pcs, profile sheet 42.52" x 17.7"/pcs.These corrugated panels are bendable and highly malleable.Very easy to install and maintain. Comes with 1 pair of gloves,100 screws

- VERSATILE USAGE: The Corrugated roof panels protection make an excellent cover for temporary garages, decks, patios, carports, sheds, small equipment storage, mobile homes, greenhouses, chicken coops,yard fence and other related fields about furniture, architecture, hardware, and transportation. Perfect for DIY enthusiasts

- BEST SERVICE:We're sure you'll be impressed by our corrugated metal roofing panels, If you have any questions, concerns, or require assistance with installation or maintenance of our metal roof panels, we providing timely support and solutions to meet your needs

Specifications

| Color | Black |

| Size | 10pcs/42.52X17.7 inch |

| Unit Count | 1 |

Related Tools

Corrugated galvanized steel roofing panels (10 pieces, each 42.52 × 17.7 in, 0.01 in thick) in black provide lightweight, weather-resistant coverage for roofs and siding. They are bendable, reusable, and include 100 screws and a pair of gloves for installation; typical applications include sheds, patios, carports, greenhouses and chicken coops.

ADRUEKMV Metal Roofing Panels - Corrugated Galvanized Roof Panels Black 10 Pcs Waterproof Siding Panels for Outdoor House Storage Chicken Coop Patio Garages Sheds Review

Why I tried these panels

A recent backyard refresh hinged on a small detail: durable, clean-looking cladding that I could install solo without lugging 8-foot sheets up a ladder. That led me to the ADRUEKMV metal panels—a compact, black, corrugated option that ships in a 10-pack, each piece measuring 42.52 by 17.7 inches and about 0.01 inches thick. The kit includes 100 screws and a pair of gloves, which sounds minor but actually nudges you to start the job the same day they arrive.

I used them in two contexts: as a vertical accent cladding for an outdoor kitchen/bar face and as roofing/siding on a small garden shed. The compact size made both projects surprisingly manageable, with caveats that are worth understanding up front.

What stands out

- Size and handling: At roughly 3.5 feet by 1.5 feet per panel, these are easy to move, lift, and align by one person. That’s a big advantage over full-length roofing sheets if you’re working alone or in a tight space.

- Finish and look: The black finish reads modern and crisp. On vertical applications—bar fronts, accent walls, privacy screens—it looks great.

- Flexibility: The thin gauge makes them bendable enough to conform to gentle curves or imperfect framing. That’s helpful on DIY projects where everything isn’t laser-straight.

- Included hardware: 100 screws and gloves get you started. You’ll likely want more screws and, if you care about a seamless look, black fasteners instead of the included silver screws.

What you need to know about thickness

These panels are thin—about 0.01 inches—roughly in the 30–31 gauge range. That’s lighter than the 29-gauge corrugated sheets you’ll find at a lumber yard. The upside is weight and workability; the downside is rigidity and dent resistance.

- Expect more flex. They can “oil can” (visually ripple) if the framing is uneven or the screws aren’t spaced well.

- Plan for more fasteners and closer framing. On the shed roof, I used purlins at 12-inch centers and ran screws at every other corrugation along edges and 12–16 inches on center up the length. That tightened everything up and eliminated chatter in the wind.

- Not for primary house roofing. For a patio cover, coop, shed, carport, greenhouse shading, or cladding, these are fine with proper support. I wouldn’t use them for a main residence roof or in very high-wind coastal zones.

Cutting and installation

I cut most pieces with aviation snips and a double-cut shear; both preserved the paint and galvanizing at the cut edge better than an angle grinder would. If you do use a grinder, expect to touch up the edges—heat can scorch the coating and invite rust. Deburr sharp edges no matter what you use.

Installation went quickly for two reasons: manageable size and predictable corrugation. A few tips that made a difference:

- Overlaps: For roofing, I used at least one corrugation of side lap and a 4–6 inch end lap depending on slope. On gentle slopes (under 3:12), increase end lap and consider butyl tape in seams for better water tightness.

- Screw placement: Screws with neoprene washers should go on the ridge of the corrugation where water doesn’t pool. Work from the fixed edge outward to keep lines straight.

- Framing prep: Flat, consistent framing is everything with thin panels. If you can, run a straightedge across your purlins or furring before you start and shim where needed.

- Edge protection: Field-cut edges will be the first place rust appears. I hit mine with a rust-inhibiting primer and a black topcoat.

- Discoloration and galvanic issues: Avoid direct contact with copper-treated lumber without a barrier tape, and use compatible fasteners to prevent galvanic reactions.

The included screws are serviceable for light-duty installs, but they’re silver. I swapped to black self-drilling roofing screws for the visible faces of the bar surround and used the included hardware on the hidden runs. If appearance matters, consider doing the same.

Coverage reality check

On paper, each panel is 42.52 by 17.7 inches (3.543 by 1.475 feet), or about 5.23 square feet. After typical overlaps—one corrugation on the side and around 4 inches on the end—you’ll net closer to ~4.4–4.6 square feet per panel, depending on your slope and seam choices. That puts the 10-pack at roughly 44–46 square feet of coverage in real-world conditions. Plan your quantity with those overlaps in mind and buy one extra pack if your layout is fussy; the short length creates more seams than full-size sheets, but also reduces waste.

Performance in the weather

We had a few heavy summer storms after installation. Drainage is good thanks to the corrugation, and the finish shed water fine. The key is the slope: corrugated panels reward a decent pitch. On the shed roof at around 3:12, I added butyl tape under the end laps and foam closures at the eaves and ridge; that kept wind-driven rain from sneaking in. Without closures, expect bugs and blown mist to find a way.

Noise is a consideration. Thin metal is louder in rain. On the shed, I stapled a synthetic underlayment to the purlins and added a thin foam tape along the ridges before paneling; that cut the drumming to an acceptable level. For a patio cover directly above a seating area, I’d recommend an underlayment or even a thin plywood deck beneath, depending on your tolerance for sound.

Durability and maintenance

Galvanized steel with a painted finish holds up well when edges are sealed and fasteners are correct. Black absorbs heat, so the panels warm quickly in sun, which can accelerate expansion/contraction and show minor oil canning if the screws are sparse. I don’t mind a bit of movement on a shed or bar face. For high-visibility walls, take your time on layout and fastener spacing, and avoid overdriving screws, which dimples the ridges and mars the finish.

Expect to occasionally rinse off dust and pollen if the panels are vertical; on a roof, debris tends to shed naturally. Inspect cut edges annually and touch up as needed. The paint took touch-up well.

Where these panels shine

- Outdoor kitchen/bar faces, privacy screens, and accent walls

- Small sheds, chicken coops, equipment shelters

- Patio or pergola covers with adequate slope and purlin spacing

- Temporary structures and DIY projects where easy handling matters

What they’re not ideal for: main home roofing; long, unsupported spans; very windy sites without dense fastening; greenhouse roofs where you actually want light transmission (these are opaque black).

What I’d change

- Offer black fasteners in the box. The included 100 screws are fine structurally, but the silver heads pop visually against black.

- A slightly heavier gauge option would broaden use cases. Even a move to 29 gauge would address dent resistance without losing DIY friendliness.

- Include foam closure strips and a roll of butyl tape as an add-on kit. Most first-time users don’t realize they’ll want them until they’re midway through.

Buying advice

- Calculate coverage using net dimensions after overlaps, not the listed size.

- Order extra screws; plan on more than 10 per panel if you have close purlin spacing.

- If aesthetics matter, buy color-matched screws and touch-up paint.

- Use snips or shears instead of a grinder to preserve the coating.

- Add closures and butyl tape for weather-exposed roofs, especially at low pitch.

Recommendation

I recommend these ADRUEKMV metal panels for light-duty roofing and cladding where easy handling, a clean black finish, and straightforward installation are priorities. They excel on sheds, coops, patio covers with proper support, and as modern-looking accent cladding on outdoor builds. The thin gauge demands closer framing and thoughtful fastening, and they’re not a substitute for heavier, full-length roofing on occupied structures or high-wind sites. If you go in with the right expectations, the right accessories (color-matched screws, closures, butyl), and a bit of planning around overlaps and slope, they deliver a tidy, weather-shedding skin at a DIY-friendly scale.

Project Ideas

Business

Pre-cut Awnings & Patio Kit Service

Offer pre-cut, ready-to-install awning and small-patio roofing kits that use the panels plus a simple rafter/frame package, screws, and step-by-step instructions. Market to homeowners wanting a DIY upgrade or small contractors who need quick installs. Provide size options, fast shipping, and optional installation add-ons for higher-margin services.

Mobile Tiny-Structure Builder (Sheds / Coops)

Start a local service building small structures—storage sheds, chicken coops, small greenhouses—using these lightweight panels for roofing and siding. Emphasize speed, durability, and low-cost compared with full construction. Offer customizable layouts, delivery + assembly, and add-ons like vents, windows, or insulation to increase average order value.

Upcycled Home Decor Shop

Produce and sell finished home décor and furniture items made from the panels: headboards, wall art panels, planters, and industrial shelving. Target online marketplaces, craft fairs, and local boutiques. Create tiered pricing (raw panels, DIY kits, finished goods) and promote the environmentally friendly upcycling angle.

Event & Market Shelter Rental

Create portable market stalls, photo-backdrop walls, or event shelters using assembled corrugated-panel frames that can be rented for farmers markets, craft fairs, weddings, and pop-ups. Black panels offer a sleek, neutral backdrop that photographers and vendors appreciate. Charge per day, offer delivery/setup, and maintain a fleet with modular sizes to serve diverse clients.

Creative

Corrugated Garden Planters

Use the panels to build modular raised garden beds or tiered planter boxes. Cut panels to size, join with metal brackets or angle iron for corners, and line with landscape fabric to retain soil. The black galvanized finish absorbs heat to extend the growing season, and panels can be stacked or linked to create long planter rows or compact, vertical gardens for patios.

Industrial Headboard or Accent Wall

Create an industrial-style headboard or an accent wall for indoor or covered outdoor spaces by mounting whole or staggered sections of the corrugated panels to a plywood substrate. Leave some panels whole and distress a few edges for character, or combine with reclaimed wood trim and backlighting for dramatic effect. This is a low-cost, durable option that gives modern, textured visual interest.

DIY Outdoor Shower / Privacy Booth

Build a sturdy, weatherproof outdoor shower enclosure or private changing booth using the panels as walls and a simple wood or metal frame. The panels' waterproof and corrosion-resistant properties make them ideal for wet environments, and the corrugated pattern helps water runoff. Add a hinged door made from a panel, some ventilation cutouts, and a floor grate for a functional, attractive installation.

Upcycled Metal Furniture and Shelving

Cut and bend panels into tabletops, cabinet faces, shelving backs, or bench seats paired with steel or reclaimed wood frames. Corrugated sheets are lightweight yet rigid and produce a distinctive industrial look. Protect edges with trim and seal cut edges to prevent sharpness; finish with cushions or wood tops to make the pieces comfortable and market-ready.