Features

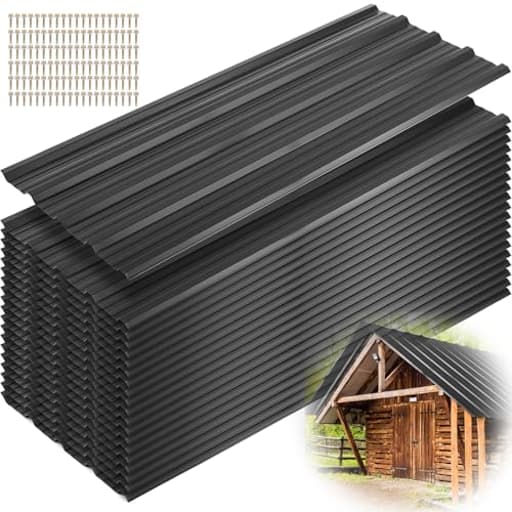

- Comprehensive Package: this package comes fully equipped with 20 pieces of heavy duty metal roofing panels and 120 screws, making sure you have everything you need for assembly; Each panel is conveniently furnished with 6 mounting screws to ensure a secure and hassle free installation process

- Reliable Material: constructed from galvanized steel, these metal siding panels are designed to offer robustness and resistance against weather related damages and corrosion; The reliable material choice allows the panels to withstand harsh conditions while offering extended use

- Ideal Size for Commercial Buildings: each corrugated roofing panels measures approximately 43.3 x 17.72 inches, providing a coverage area of over 106 sq.ft from 20 pieces; At a thickness of 0.01 inch, these metal panels are ideally suited for commercial buildings, light structures like carports, or garden sheds

- Hassle-free Installation: these corrugated metal sheets can be bent and molded according to your requirements, making them an ideal choice for DIY enthusiasts; Use the included screws to easily install them according to your specific construction needs

- Versatile Use: these metal roof panels offer versatile application options; They can be applied for constructing roofs of sheds, garden fences, aisle roofs, garages, gazebos, patios, chicken coops, outdoor storage rooms and terraces; With their sleek black finish, these metal roofing panels can complement your structures while offering reliable protection

Specifications

| Color | Black |

| Unit Count | 20 |

Related Tools

Set of 20 corrugated galvanized steel roofing/siding panels (43.3 x 17.72 in each) with 120 screws, providing about 106 sq ft of coverage. Panels are 0.01 in thick, black-finished, can be bent or cut for installation, and are intended for roofs and siding of light structures such as sheds, carports, gazebos, patios, and commercial outbuildings.

Yaocom 20 Pcs Metal Roofing Panels 43.3" x 17.72" Corrugated Galvanized Steel Roof Panels Metal Siding Panels with Screws 106 Sq.ft Gazebo Top Cover for Pergola Patio Garden Mobile Home, Black Review

Why I chose the Yaocom panels for small structures

I needed a lightweight, easy-to-handle roofing option for a backyard pergola and some siding for a small garden shed. Traditional 26–29 gauge roofing would have been overkill (and heavy) for those projects, and cutting long sheets on sawhorses in a tight yard is never fun. The Yaocom panels—short, corrugated galvanized sheets with a black finish—fit the brief: manageable size, DIY-friendly, and a clean look.

Each panel measures 43.3 by 17.72 inches, and the kit ships with 20 panels and a bag of screws. On paper, that’s about 106 square feet of coverage. In practice, your coverage will be less once you account for side-lap and end-lap. Still, for pergolas, lean-tos, chicken coops, and small outbuildings, this set hits a convenient sweet spot.

Build quality and finish

At 0.01 inches thick, these are thin steel panels—roughly in the realm of 30–31 gauge. That’s intentional. The thin stock keeps weight low and makes bending and cutting straightforward, which is perfect for small structures where you don’t need structural roofing. The galvanization offers baseline corrosion resistance, and the black topcoat (painted finish) adds a bit more protection while delivering a modern look that pairs nicely with most backyard builds.

A few practical notes from use:

- The finish is reasonably durable for DIY handling, but it will scratch if dragged across rough surfaces or cut with a grinder. I had better results cutting with aviation snips and a nibbler to protect the coating.

- As with any galvanized panel, cut edges are more susceptible to rust over time. I hit my cut lines with a cold galvanizing spray and a touch-up of black paint to be safe.

- The corrugation is consistent panel-to-panel, which made alignment and side-lap straightforward.

Size and coverage: plan your overlaps

The headline coverage (about 106 square feet for 20 panels) assumes no overlap. In real installations:

- Side-lap: I overlapped by one corrugation.

- End-lap: I used a 6-inch overlap on a low-slope pergola bay and 8 inches on a very shallow section.

With those overlaps, my effective coverage was closer to 90–95 square feet for the set. If your roof pitch is very shallow or you’re in a windy area, be conservative and plan even more overlap. Because each panel is only 43.3 inches long, multi-row installations will have more seams than full-length roofing sheets—perfectly fine for light-duty applications, but something to factor into layout and waterproofing.

Installation experience

These panels are about as DIY-friendly as metal roofing gets. A few things that worked well for me:

- Layout and supports: I ran purlins at 16 inches on center to keep the thin panels supported and avoid oil-canning. If you go wider, expect some flex and a noisier roof in the rain.

- Cutting and shaping: Snips were my go-to for trimming length and notches; a nibbler made quick work of side cuts. The panels are bendable enough to conform to slight curves or create drip edges, but keep bends gentle to avoid kinking.

- Fasteners: The kit includes screws. For roofing, I supplemented with additional roofing screws with EPDM washers to hit every purlin and secure the overlaps. On corrugated profiles like this, I prefer driving screws at the crest for roofing applications to keep water out, and at the valley for vertical siding.

- Overlaps and sealing: One-corrugation side-lap worked well. I added a bead of butyl tape under end-laps on the low-slope section. Foam closure strips at eaves and ridges help keep out wind-driven rain and pests; these aren’t included but are worth sourcing to match the profile.

- Drilling and driving: Pre-drilling through two overlapped panels kept holes clean and reduced paint chipping. Drive screws snug—don’t over-compress washers.

With two people, I installed a 100-square-foot pergola cover in an afternoon, including cutting and trim. Working solo is doable thanks to the short length and low weight.

Performance in weather

On the pergola and shed, the panels handled a couple of blustery, rainy days without issues. Proper overlap and enough fasteners are the key. A few performance observations:

- Water management: With a reasonable pitch and sealed end-laps, I saw no leaks. On very shallow pitches, I’d recommend stepping up end-lap sealing and being meticulous with fastener placement.

- Wind: Thin panels are only as wind-ready as your fastening pattern. The six screws per panel notion is light for roofing; I used more to tie into each purlin and lock down seams. Installed this way, the panels stayed put through gusty conditions common in my area.

- Noise and heat: Rain is noticeable on any metal roof, and thin panels are louder. Underlayment or even a layer of corrugated plastic under the steel can soften the sound. The black finish absorbs heat; in full sun, the panels get warm and can raise temperatures beneath a pergola. The trade-off is low glare and a sharp look.

Use cases and limitations

Where these panels shine:

- Pergolas, gazebos, lean-tos, and patio covers

- Sheds, chicken coops, and small outbuildings

- Vertical siding and windbreaks

- Temporary or seasonal structures

Where I’d think twice:

- High-wind zones or open exposures without upgrading fastener count and overlap strategy

- Heavy snow loads—these are not structural roof panels

- Coastal environments—galvanized steel will corrode faster in salt air; consider aluminum or a heavier galvalume option

- Walkable roofs—this gauge dents easily and isn’t meant for foot traffic

Practical tips to get the most from the panels

- Plan coverage with overlaps in mind. Sketch the layout, mark purlin lines, and calculate end-lap loss before you cut.

- Use closure strips and butyl tape at critical seams to improve water resistance.

- Add fasteners. Hitting every purlin and locking down overlaps makes a big difference in wind and rattle.

- Cut with snips or a nibbler to protect the finish. If you use a grinder, expect to touch up edges.

- Touch up cuts and scratches with a galvanizing primer and black paint.

- Wear gloves—the cut edges are sharp—and eye protection when cutting.

Durability and maintenance

For light-duty use, these panels should hold up well. The galvanization plus painted finish is a solid combination against rain and sun. Periodic checks help: look for lifted screws, chipped edges, or accumulated debris at overlaps. If you keep edges touched up and fasteners snug, the panels should provide several seasons of reliable service on small structures. I store leftover sheets flat and dry to avoid white rust.

Value

You get 20 panels and a bag of screws in one box, which is convenient for small projects. The manageable size reduces waste—you’re less likely to have big offcuts compared to full-length roofing sheets. While heavier-gauge panels will outlast these in harsh conditions, they come at a higher cost, require more robust framing, and are harder to DIY. For backyard builds, this kit hits a practical price-to-performance balance.

Recommendation

I recommend the Yaocom panels for light-duty roofing and siding projects where ease of handling, simple installation, and a clean look matter more than maximum strength. They’re a smart choice for pergolas, sheds, and similar structures if you plan overlaps carefully and use enough fasteners. The thin gauge, short length, and limited included hardware mean they’re not the right pick for high-wind, heavy-snow, or coastal applications without additional measures. But installed thoughtfully, they deliver solid protection, a tidy aesthetic, and a straightforward DIY experience.

Project Ideas

Business

Small-Roof Installation Service

Offer a niche service installing lightweight corrugated roofs for gazebos, carports, pergolas, and sheds. Market to homeowners and small businesses; price jobs by square foot plus labor (typical small-roof installs can command $10–$25/sq ft depending on region and complexity). Upsell flashing, foam tape, gutters, skylight strips, and maintenance packages. Promote via local Facebook groups, Nextdoor, and partnerships with landscape contractors.

Upcycled Home Décor & Furniture Line

Cut and repurpose panels into industrial home goods—wall art panels, coffee table tops, floating shelves, planter fronts, and headboards—and sell them on Etsy, Instagram, and local craft markets. Offer custom laser-cut or painted motifs, powder-coating, and distressed finishes. Price items by material and labor (small wall panels $40–$150, furniture pieces $150+). Use the included screws and leftover scrap for bundled DIY kits with assembly instructions.

Modular Pop-up Market Booth Rentals

Design a modular, portable booth system using the panels as quick-assembly roofs and side shields for farmers markets, craft fairs, and food vendors. Build frames that accept panels as snap-in roofs and provide transport cases; rent per event or offer subscription packages to recurring vendors. Add value with branded signage attachments, lighting packages, and setup/breakdown service. Target event organizers and local vendor associations.

Kitted Shelter & Coop Business for Small Farmers

Create and sell pre-cut kits for chicken coops, cold-frame greenhouses, and tool shelters using the panel dimensions to optimize material usage. Include pre-drilled panels, screws, cut lists, and step-by-step assembly guides or optional on-site assembly. Sell kits online and to farm supply stores; offer bulk discounts and a farm-installation service. Position kits as durable, weather-resistant solutions—highlight galvanized steel and included fasteners in marketing.

Creative

Mini Pergola with Metal Roof

Build a modern backyard pergola using the 43.3" x 17.72" corrugated panels as a sleek, weatherproof roof. Use a simple 4x4 or 6x6 timber frame sized to your panels (overlap panels by one corrugation), fasten with the included screws to purlins, and add foam tape or rubber washers for watertight seals. Because the panels are thin (0.01"), bend cut edges for safety and consider a thin insulation or acoustic layer under the roof to reduce heat and noise. Finish by painting the frame, adding string lights, and mounting gutters for water management.

Industrial Privacy Fence with Planter Boxes

Create a tall, modern privacy fence by mounting panels vertically to a timber or metal framework; stagger panel seams for visual interest. Integrate welded or screwed-on planter boxes and climbing-wire anchors to soften the look with greenery. Use cut-off panels to make decorative top caps or windbreak louvres. The black galvanized finish gives an industrial-chic aesthetic that works well around patios, pools, or urban gardens.

Accent Wall / Headboard Panels

Transform an interior or exterior wall into an industrial feature by fastening the panels directly to furring strips or a plywood substrate. Trim and miter panels for clean corners; add LED strip lighting behind seams for a backlit effect. For indoor projects, seal raw edges and attach rubber spacers to prevent vibration noise. Use a stencil or light sanding to add a faux-patina or distressed finish for a rustic look.

Compact Tool/Storage Shed or Chicken Coop Kit

Construct a small 6x4 or 8x6 shed or a predator-resistant chicken coop using these panels as both roof and siding to maximize the 106 sq.ft coverage. Frame with pressure-treated lumber, pre-cut panels to size (wear PPE), and pre-drill screw locations for cleaner installs. Offer removable side panels or hinged roof sections for easy cleaning and ventilation. The galvanized steel provides long-term weather protection for tools or poultry.