Features

- Compatible with most 3/8 in. crown staplers

- Intended for insulation, upholstery, house wrap/vapor barrier, and screen fastening

- Coated finish for interior use only

- Chisel point to reduce splitting of material

Specifications

| Crown Width (In) | 3/8 |

| Fastener Type / Gauge | 3/8 inch staples |

| Finish | Coated |

| Head Type | Chisel Point |

| Product Length (In) | 1/2 |

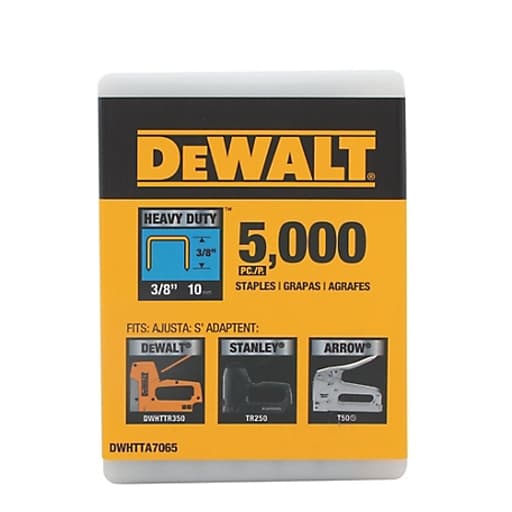

3/8-inch crown heavy-duty staples designed for use with 3/8-inch crown staplers. Suitable for fastening insulation, upholstery, house wrap/vapor barrier, and screens. The staples have a coated finish intended for interior use and a chisel point to help reduce splitting of the material.

DeWalt Heavy Duty 3/8 in. Crown Staples Review

Why these staples stayed in my pouch

I reach for staples more often than I expect—hanging house wrap on a windy day, tacking insulation batts overhead, or doing quick upholstery fixes in the shop. Over the past few months, I’ve been using DeWalt 3/8‑in. crown staples with a 1/2‑in. leg, and they’ve earned a regular spot in my fastener drawer. They’re designed for interior use and aim squarely at the bread‑and‑butter tasks: insulation, upholstery, vapor barriers, and screens. Nothing flashy—just a staple that’s consistent, predictable, and less prone to the little annoyances that slow you down.

Build quality and consistency

Staple quality matters more than it gets credit for. A slightly bent strip, an inconsistent crown, or a dull point will translate into jams, misfires, and tear‑outs. What I noticed with these staples is uniformity. The strips feel solid; I didn’t run into flaky adhesive that breaks apart when loading, and the crowns were square and centered across the pack I used. The legs are straight, with a clean chisel point that’s sharp enough to start easily but not so needle‑fine that it curls against harder material.

That chisel point is the right choice for the intended work. It cuts its way in rather than punching bluntly, which helps reduce splitting in narrow furring strips or soft pine. Drive consistency was good across multiple tools, and the crowns seated flush without excessive crushing in most materials when the tool’s depth was set correctly.

Compatibility across staplers

These are 3/8‑in. crown staples, so they fit most standard staplers in that class. I ran them through three tools: a compact pneumatic stapler, a manual squeeze stapler for light work, and a hammer tacker for speed on WRB and felt. They loaded without fuss in each one, the strips didn’t crumble when I slid them into the magazine, and I didn’t fight feeding issues. In a long afternoon of wrapping a shed, the hammer tacker didn’t balk—a small but meaningful indicator that the leg geometry and strip adhesive are dialed in.

If you’ve ever had staples that technically “fit” but don’t feed cleanly or want to twist as they enter, you’ll appreciate how uneventful these are.

Performance in common materials

House wrap and vapor barriers: The 3/8‑in. crown is wide enough to hold sheeting securely without tearing through as easily as narrower fasteners. Paired with a hammer tacker, I got a nice rhythm and clean set. In softer studs and furring, the chisel point minimized splitting, even near board edges.

Insulation: This is easy work for any staple, but the consistent set makes a difference. I could dial down the drive a touch to avoid crushing the kraft paper tabs and still got solid holding power.

Screens and fabric: For heavier screen material and canvas, these staples hold tenaciously. On light upholstery fabrics, a 1/2‑in. leg can be more than you need, especially on thin frames—consider a shorter leg if you’re working with delicate materials. On thicker upholstery backing and plywood seat bases, they’re a good match.

Sheet goods and trim: Over OSB and soft plywood, they set cleanly. On hardwood face frames or dense MDF edges, you’ll want careful depth control; like any 1/2‑in. staple, they can crush the surface if you overdrive.

Coating and corrosion notes

These staples have a coated finish intended for interior use. The thin coating helps drive and may add a touch of holding power, but it’s not a corrosion‑resistant plating. If you’re stapling in damp conditions, unconditioned spaces, or anywhere outdoors, choose a galvanized or stainless staple instead. Used where they’re meant to be used—inside, dry—they hold up just fine. I store them sealed, and they’ve stayed clean and rust‑free.

What stands out day to day

Low jam rate: I didn’t encounter jams in practical use, which I chalk up to consistent manufacturing and a properly cut chisel point. That’s especially noticeable in the hammer tacker, where cheaper staples often hiccup.

Clean entry and flush crowns: The legs don’t splay out on entry, and I saw fewer bendovers than with value‑brand boxes I’ve used.

Predictable holding power: For WRB, felt, and kraft tabs, they grab and stay put without tearing the material to shreds when you pull one out to reposition.

Honest interior rating: I appreciate that the finish isn’t pretending to be weather‑resistant. It keeps expectations clear and reduces the chance of rusty surprises.

Where they fall short

Not for exterior or damp environments: That’s by design, but it’s the biggest limitation. If you need staples for exterior trim, screen doors, or pressure‑treated lumber, look for galvanized or stainless variants.

One leg size: This model is 1/2‑in. only. It’s a versatile length for wraps and many shop tasks, but upholstery often calls for 1/4‑in. or 3/8‑in. legs depending on material thickness. If you want a one‑box solution for every upholstery job, this isn’t it.

Hardwoods require finesse: In oak or maple, an aggressive depth setting or high air pressure can crush the crown slightly or leave faint bruising. That’s true of most staples, but worth noting.

Practical tips for best results

Dial in depth: Whether pneumatic or cordless, set drive depth so the crown just kisses the surface. Overdrive crushes material and reduces holding power in thin sheets.

Manage pressure: For pneumatics, run the lower end of the tool’s PSI range on softwoods and sheet goods; bump it up only for denser stock.

Pre‑plan spacing: For WRB and vapor barriers, 6–12 in. spacing along studs generally holds fine; tighten up around openings and corners.

Mind material thickness: On thin upholstery frames and screen frames, check leg length to avoid blow‑through. When in doubt, test on a scrap piece first.

Store dry: Keep the box closed and dry. The coating isn’t there to fight humidity.

Value and who they’re for

Price varies by retailer, but these staples land in the mid‑range for brand‑name fasteners. The value proposition is in the time you don’t spend clearing jams or re‑stapling torn wrap. If you’re a remodeler, finish carpenter, weatherization tech, or a shop user who staples regularly, that reliability adds up. For a DIYer doing a one‑off project, you could go cheaper and get away with it, but you may trade dollars for frustration. I’d still pick these for a weekend WRB install simply because they make a hammer tacker behave.

Alternatives to consider

Exterior or damp conditions: Step up to galvanized or stainless staples in the same 3/8‑in. crown size.

Upholstery on delicate frames: Use a shorter leg length (1/4–3/8 in.) to prevent blow‑through and surface bruising.

Dense hardwood work: If staples are marring the surface, switch to brads or pins, or back off the drive and pre‑score the line with a marking knife to minimize fibers lifting.

The bottom line

These DeWalt 3/8‑in. crown, 1/2‑in. leg staples are the kind I like to forget about—in the best way. They feed cleanly, set predictably, and hold the materials they’re designed for without drama. The chisel point does its job reducing splits in softwood and furring, the strips are well made, and the interior‑only coating is honest and appropriate. They aren’t a one‑box answer for every upholstery or outdoor job, and you’ll want shorter legs or galvanized/stainless options for those situations. But for insulation, house wrap, vapor barriers, screens, and general interior tacking, they’ve been reliably solid.

Recommendation: I recommend these staples for anyone doing interior fastening with 3/8‑in. crown staplers, especially if you use a hammer tacker or demand jam‑free performance across different tools. They offer consistent quality and smooth feeding that make routine jobs quicker and less fussy. Just keep them inside, choose the right leg length for the task, and they’ll do exactly what you want a staple to do—disappear into the work.

Project Ideas

Business

Mobile Upholstery Refresh

Offer on-site chair and ottoman reupholstery or cushion recover services. The 3/8 in. crown staples provide consistent holding power across fabrics and vinyl, while the 1/2 in. length gives secure bite in seat bases. Market to restaurants, salons, and Airbnbs for quick turnarounds.

Screen Repair & Custom Frames

Set up a neighborhood service to repair torn window/door screens and build custom sizes. Use the wide crown staples to secure various meshes (standard, pet-resistant). Offer pick-up/drop-off or a mobile workstation for same-day service.

Acoustic Treatment Installer

Fabricate and install fabric-wrapped acoustic panels for home offices, content creators, classrooms, and small venues. The chisel-point staples reduce wood splitting in thin frames, allowing fast, clean builds. Sell packages that combine aesthetic fabrics with measured room improvements.

Interior Vapor Barrier & Insulation Retrofits

Provide interior weatherization services for basements, crawl spaces, and garage conversion projects. Use the staples to fasten vapor barriers and insulation facings to framing quickly and securely. Partner with remodelers for subcontract work and seasonal energy-efficiency upgrades.

Event Backdrops and Fabric Wall Wraps

Create reusable wood frames wrapped with fabric or printed material for weddings, pop-ups, and trade shows. The 3/8 in. crown ensures smooth, tight fabric; the coated finish suits indoor venues. Offer rental, custom branding, and install/strike services.

Creative

Upholstered Headboard or Wall Panels

Build a simple plywood frame, add foam and batting, then wrap with fabric and secure from the backside using the 1/2 in. chisel-point staples. The 3/8 in. crown holds fabric flat without tearing, and the chisel point helps avoid splitting thin frame stock. Create one large headboard or a grid of panels for a statement wall.

DIY Acoustic Panels

Make lightweight wood frames, fill with mineral wool or fiberglass, and wrap with breathable fabric. Staple the fabric to the rear of the frame using the heavy-duty 3/8 in. crown staples for even tension. Great for home studios, podcasts, and theater rooms. The coated finish is perfect for interior-only use.

Custom Window Screens

Assemble simple pine frames and staple screen mesh taut with the 3/8 in. crown staples. The wide crown grabs mesh well, and the chisel point reduces splitting in narrow frame rails. Ideal for replacing damaged screens or creating pet-proof screens with stronger mesh.

Fabric-Covered Bulletin Boards

Wrap cork or rigid foam boards with decorative fabric and staple from the back. The 3/8 in. crown spreads holding force to keep fabric smooth and wrinkle-free. Create coordinated boards for kitchens, kids’ rooms, craft rooms, or home offices.

Dining Chair Reupholstery

Refresh dining chairs by removing old fabric, adding fresh foam/batting, and stapling new fabric neatly to the seat underside. The heavy-duty staples provide strong grip in plywood bases, and the chisel point prevents splitting in older frames.