Features

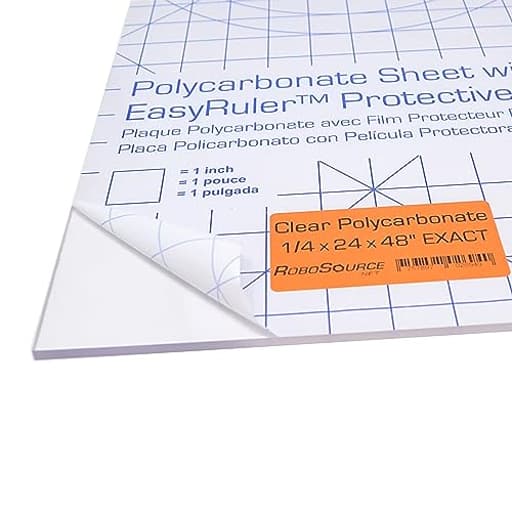

- Polycarbonate / Polycarb (PC sheet) is the superior choice over Plexiglass for use around the home, workshop, car, and in the VEX Robotics Competition. Extremely easily workable without cracking or chipping. Exclusive EasyRuler Protective Film makes work even easier, then just peel it off to expose a pristine, smooth, clear surface.

- Shatter resistant, easy to cut, drill, bend, and thermoform. Use simple tools like snips or hacksaws to cut and standard drill bits without cracking or fracturing. Simple to bend with a heat gun, may also be cold-bendable. Thermoformable, often used for vacuum molding.

- This polycarbonate plastic sheet is manufactured from 100% virgin, brand-name polycarbonate PC resin. This means you get the same high quality clear plastic sheet you expect with the exclusive EasyRuler film you can't find anywhere else. This polycarbonate sheet is UV stabilized, making it suitable for general-purpose applications with moderate sunlight exposure. For significant direct sun exposure over extended periods, UV coated sheets are recommended.

- Exact size sheet is precisely 24x48", unlike other nominal sheets that can be up to 1/4" smaller than specified. Includes a single accurately square & straight cut sheet of 1/4" (0.236", approx 6mm/6.35mm) thick Polycarbonate. 2 foot by 4 feet, 1/4 inch (0.236 inches, approx. 0.25 or 0.220 inch) thick.

- Polycarbonate clear plastic sheets are easier to work with than Plexiglass acrylic sheets as they do not crack, fracture, or shatter from cutting, drilling, or impact. Safer and more practical than glass panes.

Specifications

| Color | Transparent |

| Unit Count | 1 |

Related Tools

This transparent polycarbonate sheet measures 24 x 48 x 0.236 inches (approx. 6 mm) and is suitable for window panels, hobby, home, DIY, and light industrial uses. Made from virgin polycarbonate with a removable protective film, it is shatter-resistant and can be cut, drilled, bent, or thermoformed without cracking, and is UV-stabilized for moderate sun exposure.

Robosource Polycarbonate Clear Plastic Sheet 24" X 48" X 0.236" (1/4") Exact with EasyRuler Film, Shatter Resistant, Easier to Cut, Bend, Mold Than Plexiglass. Window Panel, Hobby, Home, DIY, Industrial, Craft Review

Why I keep a 2×4 sheet of polycarbonate in the shop

A 24×48×1/4-inch clear panel is one of those unsung heroes in a workshop. I cut guards, splash panels, and quick window replacements from it regularly. The Robosource polycarbonate sheet slots right into that role: it’s true to size, tough, and—most importantly—easy to work with using ordinary tools.

I used this sheet for two recent projects: a clear replacement panel for a shop-door window and a hinged face for a storage cabinet. Along the way I cut, drilled, edge-finished, and did a gentle heat bend. The experience was predictably drama-free, which is exactly what I want from polycarbonate.

Build and clarity

Out of the box, the sheet is dead-on at 24×48 inches and a hair under 1/4 inch thick (0.236 inches). The corners were square and the faces scratch-free beneath the protective film. It’s fabricated from virgin polycarbonate, which shows in the optical clarity—no tint, haze, or wavy distortion on my sample.

Robosource’s protective film carries a printed grid/ruler. It sounds gimmicky until you start laying out holes and cuts. I marked centerlines and offsets directly on the film, made all my cuts and drill points, then peeled it off to reveal a pristine surface. It saved me time and kept Sharpie off the actual material.

Workability: cutting, drilling, and finishing

Polycarbonate is famously forgiving compared to acrylic. This sheet lived up to that reputation.

- Cutting: I ripped it on a table saw with a 60-tooth fine-finish blade and a steady feed. The cut edges came out clean with minimal feathering. For smaller cutouts, a jigsaw with a fine metal/plastic blade at medium speed produced smooth curves without melting or chipping. If you don’t have those tools, a hacksaw with a fine blade works too—just support the cut to prevent chatter.

- Drilling: Standard twist bits worked without any drama. I back up the exit side with scrap to prevent blowout and use a slow-to-moderate speed with light pressure. For larger holes, a step bit is my go-to; it leaves round, burr-free openings with less heat. I intentionally drilled close to an edge to test for stress cracks and didn’t see any crazing.

- Edge finishing: A quick pass with 220-grit followed by 400-grit sandpaper gives a satin edge that’s safe to handle. You can go finer if you want a near-polished look. I avoid flame polishing polycarbonate; it’s tempting, but it can create surface stress.

For bending, a simple line bend with a heat gun over a wood straightedge worked well. Polycarbonate transitions cleanly once it’s evenly warm; maintain a gentle, constant heat and check frequently to prevent bubbles. It will cold-bend for large radii, but if you need crisp angles, apply heat.

Strength and impact resistance

This is where polycarbonate shines. A 1/4-inch sheet is stiff enough for small panels and guards, and it shrugs off the kind of incidental impacts that would crack acrylic. For my shop-door window, it’s an easy safety upgrade over glass without the brittleness of acrylic. It’s not bullet-resistant, of course, but for general home, hobby, robotics, and light industrial use, the toughness is excellent.

One caveat: polycarbonate is less scratch-resistant than glass or hard-coated plastics. If your application involves frequent wiping or abrasion, plan accordingly—use soft cloths and mild soap, or add a sacrificial protective film if needed. This version is UV-stabilized for moderate sun exposure, but it’s not a hard-coated exterior glazing; for long-term outdoor installations in direct sun, a UV-coated or abrasion-resistant variant will last longer.

Fit, finish, and accuracy

The sheet I received was precisely cut and evenly thick across its area. Diagonal measurements matched, so squareness was on point—helpful when you’re using factory edges for reference. The film peeled cleanly in large sheets without leaving adhesive behind.

At roughly 2×4 feet and just under 1/4-inch thick, it’s sturdy without being unwieldy. One person can move and cut it easily, and it sits flat on a bench without curling.

Practical tips from the build

- Keep the protective film on during fabrication. Peel back only where you need to drill, then remove the rest after installation to minimize scratches.

- Tape your cut lines with painter’s tape to reduce surface scuffs from the saw base. Mark on the film, not the plastic.

- Use a sharp, fine-tooth blade and steady feed rate. If you see melting, slow down and let the blade clear chips.

- Back the workpiece during drilling and use a step bit for larger holes. Deburr with a light countersink for clean hardware seating.

- Account for thermal expansion if you’re framing it like glass. Polycarbonate moves more than glass; oversize your holes slightly and use washers or grommets.

- Clean with mild soapy water and a microfiber cloth. Avoid ammonia-based window cleaners; they can cause surface haze and stress cracking over time.

Use cases that suit this sheet

- Window replacements and door lites in shops and sheds

- Splash guards for benchtop tools and coffee bars

- Cabinet doors and display panels

- Machine guards and light enclosures

- Robotics chassis panels and shields

- Templates and jigs where a clear, flat surface helps

For my cabinet project, I hinged the panel with small screws and installed pulls. The material holds screws well when you pre-drill properly and avoid overtightening. For adhesives, two-part epoxy and dedicated polycarbonate adhesives work; avoid cyanoacrylates (super glue) near stressed areas because they can cause crazing.

Durability outdoors

This sheet is UV-stabilized, which helps resist yellowing under moderate sun exposure. On a covered porch or behind a storm door window, that’s typically sufficient. If you’re building a greenhouse or a south-facing exterior panel in full sun, I’d step up to a UV-coated or hard-coated polycarbonate to maximize lifespan and scratch resistance. That’s not a knock on this sheet—it’s about selecting the right variant for the duty cycle.

Packaging and delivery

My sheet arrived in a large carton with protective film intact and corners in good shape. For mail-order plastics, I always inspect edges and plan my cuts to trim a small amount off each side anyway; it gives me a clean factory-free edge and eliminates any minor shipping nicks. If you need full use of the factory edges as-is, give the panel a close look on arrival.

Value

Polycarbonate costs more than acrylic, but the time and frustration saved—no cracking, no edge shatters, fewer remakes—makes it worth it for me. Add the accurate sizing and the genuinely useful ruler film, and the overall value is strong for shop, hobby, and light industrial work.

Limitations to know

- Scratch resistance is modest without a hard coat; protect the surface in abrasive environments.

- Not intended as a structural member; support it appropriately to avoid flexing over long spans.

- For high-UV, long-term exterior installs, choose a hard-coated or UV-coated grade.

None of these are deal-breakers; they’re inherent tradeoffs with standard polycarbonate.

Recommendation

I recommend the Robosource polycarbonate sheet. It’s precisely cut, crystal clear, tough, and truly easy to work with using common tools. The EasyRuler protective film speeds layout and keeps the surface pristine until the last step, and the UV stabilization covers typical indoor and semi-outdoor uses. If you need a transparent panel for home, hobby, or shop projects and you value a material that won’t crack when you drill it or chip on the saw, this sheet hits the sweet spot. Choose a hard-coated or UV-coated variant only if your application demands long-term abrasion resistance or heavy, continuous sun exposure; otherwise, this is the right everyday sheet to keep on hand.

Project Ideas

Business

Made‑to‑order sneeze guards & countertop shields

Offer custom cut 24"x48" panels with pre‑drilled holes, slotted mounting brackets, or finished edges for small businesses, salons, and cafes. Batch cut common sizes to reduce per‑unit cost and upsell installation hardware and shipping kits.

Small‑batch signage & menu boards

Produce durable, UV‑stable clear or backlit sign faces and menu panels for cafes, boutiques, and events. Apply vinyl graphics or direct‑print, offer rounded corners and drilled mounting points, and target local businesses for faster turnaround.

Prototype & vacuum‑forming service

Use the sheet’s thermoformability to offer quick‑turn prototyping and small runs of formed parts (hoods, guards, housings) for inventors and product designers. Market as a faster, lower‑cost alternative to CNC or injection tooling for early iterations.

Etsy / Shopify products: display boxes & cloche sets

Sell finished products like nested plant cloches, clear collectible cases, and terrarium lids that highlight the shatter‑resistant benefit versus glass. Offer customization (engraving, vinyl logos, sizes) and kit versions for DIY customers.

Workshops and DIY kits for makerspaces

Run hands‑on classes teaching cutting, drilling, heat bending, and simple vacuum forming with this polycarbonate. Monetize by selling starter kits (pre‑cut pieces, fasteners, instructions) and offering group rates to schools and hobby clubs.

Creative

Mini greenhouse / seedling cold frame

Use a 24"x48" sheet to cut and hinge a clear cover that sits over seed trays or raised beds. The UV‑stabilized polycarbonate lets light through while protecting seedlings from wind and light frost; heat‑bend edges to form corner panels and use simple hinges or removable clips for access.

Thermoformed plant cloches & domes

Thermoform sections with a heat gun or small vacuum setup into dome or cone cloches to protect individual plants. The sheet’s shatter resistance and ease of shaping make lightweight, reusable cloches that are safer than glass and can be nested for storage.

Clear display cases / shadow boxes

Cut and drill panels to build 24"x12" or smaller display boxes for collectibles, model kits, or retail counters. Polycarbonate drills and screws cleanly without cracking—finish seams with plastic cement or silicone for a professional look.

Splash guards, pet barriers, or aquarium lids

Create a custom splash guard for kitchen or workshop stations, a clear pet divider for vehicles, or a fitted aquarium lid. Easy to cut and drill for cords/filters, and safer than glass for high‑impact areas.

Curved lamp shade / light diffuser

Heat‑bend the sheet into an elegant curved shade or wrap it around a frame as a diffuser. Sand, frost, or use diffusing spray to soften light—ideal for DIY pendant lamps and photography light modifiers.