Features

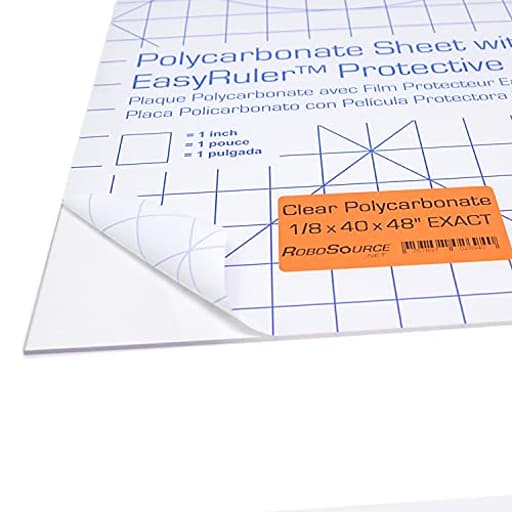

- Polycarbonate / Polycarb (PC sheet) is the superior choice over Plexiglass for use around the home, workshop, car, and in the VEX Robotics Competition. Extremely easily workable without cracking or chipping. Exclusive EasyRuler Protective Film makes work even easier, then just peel it off to expose a pristine, smooth, clear surface.

- Shatter resistant, easy to cut, drill, bend, and thermoform. Use simple tools like snips or hacksaws to cut and standard drill bits without cracking or fracturing. Simple to bend with a heat gun, may also be cold-bendable. Thermoformable, often used for vacuum molding.

- This polycarbonate plastic sheet is manufactured from 100% virgin, brand-name polycarbonate PC resin. This means you get the same high quality clear plastic sheet you expect with the exclusive EasyRuler film you can't find anywhere else. This polycarbonate sheet is UV stabilized, making it suitable for general-purpose applications with moderate sunlight exposure. For significant direct sun exposure over extended periods, UV coated sheets are recommended.

- Exact size sheet is precisely 40x48", unlike other nominal sheets that can be up to 1/4" smaller than specified. Includes a single accurately square & straight cut sheet of 1/8" (0.118", approx 3mm/3.2mm) thick Polycarbonate. 40 inches by 4 feet, 1/8 inch (0.118 inches, approx. 0.125 inch) thick.

- Polycarbonate clear plastic sheets are easier to work with than Plexiglass acrylic sheets as they do not crack, fracture, or shatter from cutting, drilling, or impact. Safer and more practical than glass panes.

Specifications

| Color | Transparent |

| Unit Count | 1 |

Related Tools

This 40 x 48 inch, 0.118-inch (approx. 3 mm) clear polycarbonate sheet is a shatter-resistant glazing and fabrication material for window panels, hobby, DIY, and industrial uses. Made from 100% virgin polycarbonate and supplied with a removable protective film, it resists cracking during cutting, drilling, bending, and thermoforming and is UV-stabilized for moderate sun exposure.

Robosource Polycarbonate Clear Plastic Sheet 40" X 48" X 0.118" (1/8") Exact with EasyRuler Film, Shatter Resistant, Easier to Cut, Bend, Mold Than Plexiglass. Window Panel, Hobby, Home, DIY, Industrial, Crafts Review

Why I reached for this sheet

I needed a clear, tough panel I could cut to shape without the usual cracking drama you get with acrylic. For a temporary window insert and a couple of shop guards, I picked up the Robosource polycarbonate sheet in the 40 x 48 x 0.118 inch size. It’s a straightforward product—clear, shatter resistant, and supplied with a protective film—but the execution matters. After a few weekends of cutting, drilling, and bending it, I have a good sense of where it shines and where you should be careful.

What stands out

- It’s truly workable. The defining trait of this sheet is that it behaves well with common shop tools. Cuts are predictable, holes don’t spider-crack, and line bends are achievable with a heat gun.

- The EasyRuler protective film is more than a gimmick. The printed grid made layout faster, kept the surface clean while I worked, and peeled away cleanly afterward.

- The size is exact and square. My sheet measured precisely 40 by 48 inches and the edges were reliably true. That matters when you’re dropping it into a frame with tight tolerances.

Cutting and drilling: low drama, clean results

I tried several approaches to see what an average DIYer will encounter:

- Jigsaw: A fine-tooth blade (14–20 TPI) at medium speed, with the sheet supported on both sides, produced clean cuts with minimal edge melt. I left the protective film on and added painter’s tape along the cut line as a belt-and-suspenders approach against scuffs.

- Circular/table saw: A fine-tooth blade meant for plastics (or a sharp plywood blade) works if you feed steadily and avoid lingering. Support the offcut to prevent vibration. Edge quality was the best with this method.

- Hand tools: A hacksaw will get you there for short cuts. Aviation snips can work on this thickness for small trims, but they can slightly curl the edge; not my first choice for long, straight cuts.

For drilling, standard twist bits are fine. I stepped up hole sizes gradually and backed the work with scrap wood. A step drill made especially clean holes for mounting points. The key is to let the bit cut (don’t force it), clear chips often, and avoid high speeds that generate heat. No cracking, even close to edges.

Deburring the edges with 220/400 grit sandpaper gave a tidy finish. I wouldn’t flame-polish polycarbonate; sanding and a quick buff are safer and good enough for most applications.

Bending and forming: forgiving with heat, cautious when cold

One of polycarbonate’s advantages over acrylic is how forgiving it is when forming. I set up a simple line-bending jig with a straightedge and used a heat gun, moving in smooth passes until the sheet relaxed. With patience, bends were clean and didn’t haze or stress-whiten.

Cold bending is also possible with this thickness, but keep the radius generous. As a rule of thumb, I avoid cold bends tighter than roughly a foot radius on 1/8 inch material. If you need a sharp angle or repeated flexing, heat is your friend.

For larger thermoforming or vacuum forming, you’ll have an easier time if you preheat evenly. Remove the protective film before any serious heating—keep it on only for layout and mechanical work.

Optical clarity and surface finish

Out of the package, clarity was good—clear enough for window use and machine guards without noticeable rippling. Polycarbonate isn’t a museum-glass substitute, but this sheet is bright and uniform, with no distracting waves.

A practical note: polycarbonate is softer than glass and a bit more scratch-prone than acrylic. The protective film helps during fabrication, but once it’s installed, clean it with a soft microfiber cloth and mild soapy water. Skip abrasive pads and ammonia-based cleaners to preserve clarity.

Impact resistance and real-world toughness

If you need “won’t shatter” performance, this is the right material. I used it as a shop shield where offcuts occasionally bounce around, and it shrugged off impacts that would have chipped acrylic. It’s also noticeably lighter than glass, which made working with a full 40 x 48 sheet manageable alone.

Thermal expansion is real with polycarbonate. If you’re mounting it in a frame, leave a small clearance gap and use oversized, slotted holes so the panel can move with temperature swings. Over-tightening fasteners or hard-clamping in a tight frame can introduce stress and lead to warping over time.

UV stabilization and outdoor use

This sheet is UV-stabilized for moderate sun exposure, which is appropriate for occasional outdoor use, window inserts that aren’t sun-baked year-round, and general-purpose projects. If you’re planning a long-term exterior installation in heavy sun—think greenhouses, skylights, or a south-facing storm panel—go with a UV-coated polycarbonate instead. That extra coating does a lot to ward off haze and surface degradation over years.

Dimensions, squareness, and handling

The exact sizing is a quiet but important feature. Many “nominal” sheets run undersized; this one didn’t. Thickness measured right on spec at about 0.118 inch, and the corners were square, which sped up fitting into a frame. The protective film on both sides did its job, and mine arrived free of scuffs.

Large sheets can be a shipping gamble in general, so I always inspect before I cut. If you’re buying for a single, visible panel, plan your cuts to keep the best faces for show surfaces, and don’t peel the film until you’re done fitting.

Typical uses this sheet fits well

- Window inserts and temporary glazing

- Machine guards and shop shields

- DIY enclosures and panels for robots or RC projects

- Templates, jigs, and hobby projects that need clear, durable plastic

- Bent or thermoformed parts with modest curvature

For a permanent architectural install under heavy sun, or for applications where pristine, scratch-free optics are the top priority, consider either a hard-coated polycarbonate or acrylic (accepting acrylic’s brittleness).

What I’d improve

- Optional hard-coat or UV-coated variant: A version with a scratch-resistant or UV hard coat would broaden outdoor and high-wear use cases.

- More protective packaging for edge corners: Mine arrived in good shape, but corner blocks or reinforced edge guards would further reduce the risk of shipping dings on such a large format.

- A small offcut included in the package: A sample strip would let users dial in saw speed, drill technique, and heating before committing to the main sheet.

Tips for success

- Leave the protective film on through layout, cutting, and drilling. Peel just before installation.

- Support the workpiece fully when cutting to minimize chatter. Clamp when possible.

- Use sharp, fine-tooth blades and moderate feed rates. Let the tool cut; don’t force it.

- For mounting, oversize screw holes slightly and use washers or grommets to distribute load.

- Clean gently: mild soap and water, microfiber cloth, no solvents or ammonia.

Bottom line

The Robosource polycarbonate sheet earns its keep by being easy to work, tough in use, and true to size. I had clean cuts, stress-free drilling, and reliable bends using standard shop tools, helped along by the genuinely useful EasyRuler film. Clarity is solid for window and guard applications, and impact resistance is leagues better than acrylic.

It’s not the right choice if you need a long-term exterior panel in full sun without a UV hard coat, or if scratch resistance is paramount. But for most home, hobby, and light industrial projects that call for a clear, durable, formable sheet, this is a well-executed option.

Recommendation: I recommend this sheet to DIYers, makers, and fabricators who want a clear panel that’s easy to cut, drill, and bend without cracking. It’s especially good for temporary glazing, shop shields, and custom enclosures. If your project lives outdoors in harsh sun or needs a tougher surface, step up to a UV-coated or hard-coated polycarbonate; otherwise, this hits the sweet spot of workability, durability, and value.

Project Ideas

Business

Bespoke Sneeze Guards & Counter Shields

Offer ready-to-install sneeze guards and countertop shields for restaurants, retail, salons, and offices. Provide standard sizes and custom templates, ship flat-packed with predrilled holes and mounting hardware. Market quick turnaround, disinfectable surfaces, and the safety advantage of shatter-resistant polycarbonate.

Replacement Window & Greenhouse Panel Service

Sell cut-to-size polycarbonate replacement panels for hobby greenhouses, cold frames, sheds, and DIY projects. Offer cutting-to-fit, edge-polishing, and an upgraded UV-coated option for extended sun exposure. Package repair kits (panels + sealant + fasteners) for convenient homeowner installs.

Edge-Lit Signs & Small Lightboxes

Produce custom small-format illuminated signage using edge-lit polycarbonate panels and LED strips. Route or sand edge profiles to maximize light diffusion, combine with vinyl graphics or cutouts, and sell to boutiques, cafes, and makers. Low-weight, durable signs are attractive for pop-up shops and events.

Pre-Cut Project Kits & Workshops

Create value-added DIY kits (greenhouse panel kit, aquarium lid kit, cosplay visor kit) that include pre-cut polycarbonate parts, hardware, and step-by-step instructions. Run local hands-on workshops teaching cutting, drilling, and thermoforming techniques—charge for materials and instruction, and sell kits online as follow-up products.

Custom Pet & Vehicle Barriers

Make custom-fit pet barriers for car trunks/seats, protective window guards, and aquarium lids for pet stores and veterinary clinics. Offer measuring guides and on-site templating for perfect fit; emphasize impact resistance for animal safety and the ease of recent cuts/drill additions for vents or latches.

Creative

Modular Mini-Greenhouse / Cold Frame Panels

Cut the 40x48 sheet into hinged panels to build a lightweight, impact-resistant mini greenhouse or cold frame for seedlings. Use simple tools (jigsaw/snips, drill) to trim panels and add piano hinges or velcro attachments to a wooden frame. The UV-stabilized sheet keeps heat in while resisting cracking—peel the EasyRuler film after assembly for a pristine finish.

Custom Aquarium / Terrarium Lids

Make fitted hinged lids for aquariums or reptile terrariums that are lighter and safer than glass. Drill precise holes for lighting, heater cords, or ventilation; add cutouts with plastic-friendly saw blades for feeding ports. Polycarbonate resists impact from pets and is easy to rework if you need to add fittings later.

Curved Lamp Shades & Light Diffusers

Thermoform or heat-bend strips of the sheet into elegant curved lamp shades or LED diffusers. Edge-light clear polycarbonate with LED strips for glowing panels or sand the surface lightly (or use frosted spray) for softer diffusion. The sheet’s clarity and ability to be molded lets you create unique lighting fixtures for home or studio.

Cosplay Armor Plates & Visors

Use the sheet for clear visors, transparent armor accents, or rigid mask components. Heat-bend to shape around curves, trim with snips or a jigsaw, and drill for rivets. Because polycarbonate won’t crack like acrylic, it’s ideal for wearable pieces that need strength and clarity—leave the protective film on while working to prevent scratches.

Tool Guards & Workshop Shields

Fabricate transparent safety shields for table saws, routers, or drill presses. Cut custom-sized guard panels, drill for mounting points, and add quick-release hinges so guards flip away for access. The shatter resistance of polycarbonate makes it far safer than glass and easier to machine than acrylic.