Features

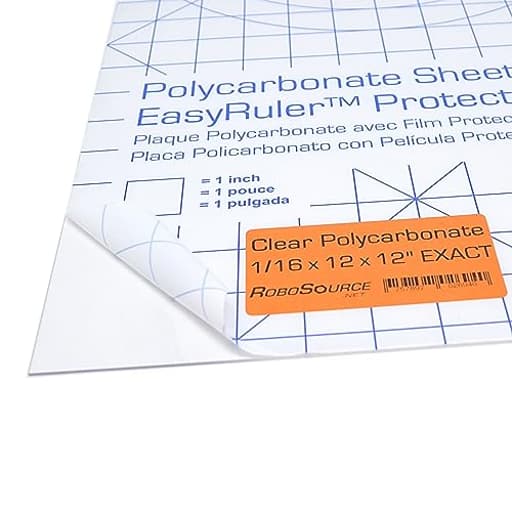

- Polycarbonate / Polycarb (PC sheet) is the superior choice over Plexiglass for use around the home, workshop, car, and in the VEX Robotics Competition. Extremely easily workable without cracking or chipping. Exclusive EasyRuler Protective Film makes work even easier, then just peel it off to expose a pristine, smooth, clear surface.

- Shatter resistant, easy to cut, drill, bend, and thermoform. Use simple tools like snips or hacksaws to cut and standard drill bits without cracking or fracturing. Simple to bend with a heat gun, may also be cold-bendable. Thermoformable, often used for vacuum molding.

- This polycarbonate plastic sheet is manufactured from 100% virgin, brand-name polycarbonate PC resin. This means you get the same high quality clear plastic sheet you expect with the exclusive EasyRuler film you can't find anywhere else. This polycarbonate sheet is UV stabilized, making it suitable for general-purpose applications with moderate sunlight exposure. For significant direct sun exposure over extended periods, UV coated sheets are recommended.

- Exact size sheet is precisely 12x12", unlike other nominal sheets that can be up to 1/4" smaller than specified. Includes a single accurately square & straight cut sheet of 1/16" (0.060 inch, approx 1.5mm/1.6mm) thick Polycarbonate. 1 foot by 1 feet, 1/16 inch (0.06 inches) thick.

- DIY Picture Frame glass sheet replacement, like PET or glass for 4x6 picture frame, 5x7 photo, 8x10 image mounting, 11x14 photo frame fixing. VEX Robotics Plastic Sheet. The best resource for VEX EDR Robotics plastic sheet. Legal for use on VEX Robotics competition robots: Rule R9 permitted.

Specifications

| Color | Transparent |

| Unit Count | 1 |

Related Tools

Clear polycarbonate sheet, precisely cut to 12" x 12" x 1/16" (≈0.060" / 1.5–1.6 mm), manufactured from 100% virgin polycarbonate and supplied with a removable protective film. The material is shatter-resistant and UV-stabilized for moderate sun exposure, and can be cut, drilled, bent, and thermoformed for uses such as window panels, picture-frame glazing, general DIY and industrial projects, and is permitted for use on VEX Robotics competition robots (Rule R9).

Robosource Polycarbonate Clear Plastic Sheet 12" X 12" X 0.0625" (1/16") Exact with EasyRuler Film, Shatter Resistant, Easy to Cut, Bend, Mold Than Plexiglass. Window Panel, Industrial, Hobby, Home, DIY, Crafts. Review

Why I keep a 12x12 polycarbonate sheet in my shop

I keep a small stash of plastics for quick fixes and prototypes, and the Robosource polycarbonate sheet has earned a dedicated spot. It’s a 12 x 12 inch, 1/16 inch thick piece of clear polycarbonate with a protective film printed with measurement markings. That sounds mundane until you actually need to cut a clean window insert, patch a tool guard, or whip up a bracket for a robotics project without a trip to the glass shop.

Over several projects I cut, drilled, bent, and even lightly thermoformed this sheet to see where it shines and where it doesn’t. Here’s how it behaved in the real world.

What I built and how it performed

- Replaced the glazing on a small picture frame: I wanted something shatter-resistant around kid-friendly spaces. The sheet cut cleanly and looked optically clear once the film came off.

- Added a clear guard for a benchtop sander: I drilled mounting holes and bent a gentle flange with a heat gun so it would sit snugly. The part has taken bumps without cracking.

- Made a small light-diffusing panel for a garage side opening: Sealed behind a trim ring and weatherstrip, it’s held up fine with day-to-day ambient light exposure.

Through those tasks, the sheet proved workable with basic tools and stable in use, as long as you respect its thickness and span limits.

Workability: cutting, drilling, and bending

Polycarbonate is far more forgiving than acrylic, and that’s evident immediately.

- Cutting: For straight cuts, a fine-tooth jigsaw blade rated for plastic produced clean edges with minimal fuzz. Tin snips handled small curved cuts without cracking. A hacksaw works too; clamp the sheet to reduce chatter. This is thin enough that you can cut cautiously with heavy scissors, though you’ll get a slight edge flare that benefits from a quick sand.

- Drilling: Standard twist bits are fine. I left the protective film on and drilled through my layout marks; no chipping on exit. For best results, use moderate speed and light pressure, and back the piece with scrap to prevent blowout. If you’re mounting with screws, slightly oversize the holes to reduce stress and allow for expansion.

- Bending and forming: Gentle cold bends are possible, but expect springback at this thickness. For tighter bends, a heat gun along a metal straightedge gave me crisp, controlled folds without bubbles. I also tried a quick vacuum pull over a simple wood form: it softened and conformed evenly. Keep the heat moving, and remove the film before heavy forming to avoid imprinting.

One thing to note: polycarbonate doesn’t “score and snap” the way acrylic sometimes does. You’ll get better, more predictable results with actual cutting tools.

Clarity and surface finish

Once the film is peeled, the surface is smooth and optically clear. There’s no haziness or color cast in indoor light. Polycarbonate is more prone to fine surface scratches than glass or hard-coated plastics, so leave the film on until final assembly and avoid dry-wiping dust. If you need scratch resistance for a high-contact surface, this isn’t the right thickness or coating—go with a hard-coated sheet.

The EasyRuler protective film is a genuinely useful touch. The printed markings make it simple to square up a cut or transfer measurements without writing on the plastic. It peels cleanly, leaving no residue.

Size accuracy and squareness

This sheet arrived exactly at 12 x 12 inches and square. That may sound obvious, but nominally sized plastics can run short; this one didn’t. It measured just about 1/16 inch thick (around 1.5–1.6 mm), which matters when you’re fitting into channels or frames.

Strength and impact resistance

At 1/16 inch, the sheet is flexible but surprisingly resilient. It shrugs off the small impacts and edge knocks that would chip or fracture acrylic of the same thickness. I wouldn’t call it structural—span it too far and it will bow—but for small panels, guards, and covers, the impact resistance is a clear win. If you need stiffness over a larger span, go thicker or add a perimeter frame.

UV and outdoor considerations

This sheet is UV-stabilized for moderate sun exposure. In my garage-side application with indirect sun, it’s been fine. For installations with sustained, direct sunlight and weather, I’d step up to a polycarbonate sheet with a UV hard coat or a product specifically rated for exterior glazing. The stabilization here is good for general use but not a substitute for a heavy-duty exterior panel.

The little things: packaging and handling

The sheet arrived flat, well protected, and unscarred. The cardboard sleeve doubles as a handy drill backing and storage for offcuts—small detail, but appreciated. The protective film stayed put through cutting and drilling, which kept the faces pristine until I was ready to peel.

Where it fits (and where it doesn’t)

Best uses I’ve found:

- Picture-frame glazing and lightweight window inserts where shatter resistance matters

- Tool guards, splash shields, and light-duty machine enclosures

- Robotics and hobby parts that benefit from easy machining without cracking

- Templates and patterns, thanks to the printed film

Less ideal:

- Long-span panels where rigidity is required (opt for thicker stock)

- High-abrasion surfaces where scratch resistance is critical (choose a hard-coated polycarbonate)

- Permanent exterior installations in full sun (consider UV hard-coated alternatives)

Tips to get cleaner results

- Keep the film on during layout, cutting, and drilling; peel at the end.

- Support the workpiece close to the cut line to minimize vibration when using a jigsaw.

- Use fine-tooth blades and moderate feed rates; you’re cutting plastic, not racing through plywood.

- Deburr with a utility scraper, then sand edges with 220–400 grit for a pleasant, safe finish.

- When heat bending, warm gradually and evenly; too much localized heat can cause bubbles.

- Oversize fastener holes slightly and avoid overtightening to reduce stress.

Value and tradeoffs

You’re paying a premium for convenience, exact sizing, and an easy-to-work-with material. For small projects, prototypes, and repairs, that premium makes sense—you avoid buying and storing a much larger sheet, and you get a piece that behaves well with common tools. If you’re covering larger areas or need multiple parts, buying larger stock and cutting it down will be more cost-effective. As a ready-to-use piece for shop tasks and hobby builds, this 12 x 12 hits a sweet spot.

Bottom line

The Robosource polycarbonate sheet is a practical, no-drama material to keep on hand. It cuts easily, drills cleanly, bends predictably with heat, and resists the kind of cracking that makes acrylic frustrating for small jobs. The protective film with measurement markings sounds like a gimmick until you use it; then it becomes a workflow nicety you miss on other sheets. It’s not the stiffest at this thickness and it’s not meant for harsh exterior duty, but within its lane—small panels, guards, hobby parts, and glazing—it does its job well.

Recommendation: I recommend this sheet for makers, DIYers, and robotics teams who need a clear, shatter-resistant panel they can shape with basic tools. It’s especially good for quick repairs, small guards, and precise prototypes where exact sizing and clean surfaces reduce rework. If your project demands long spans, heavy abrasion resistance, or permanent exposure to full sun, look for a thicker or hard-coated alternative; otherwise, this is an easy, dependable choice.

Project Ideas

Business

Custom Picture-Frame Glazing Service

Offer a local or online service cutting exact-size polycarbonate glazing to replace glass in frames (safer for kids' rooms, schools, galleries). Emphasize the exact 12x12 stock and ability to trim to common frame sizes, the EasyRuler film for scratch-free transport, and shatter-resistance as a selling point.

DIY Craft Kits (Lamp / Mini Greenhouse Kits)

Assemble and sell small kits that include pre-cut polycarbonate panels, fasteners, instructions, and LED or hinge hardware — e.g., bedside lamp diffusers, seed-starting mini-greenhouses, or dollhouse window packs. Market on Etsy/Shopify to hobbyists who want ready-to-build projects.

VEX Robotics & Educational Part Packs

Create pre-cut, competition-legal polycarbonate sheets and mounting kits tailored for VEX and educational robotics teams: mounting holes, scoring lines, and template shapes. Sell kits to schools and clubs as time‑saving, legal materials for projects and competitions.

CNC-Cut/Engraved Signage and Durable Ornaments

Use a CNC router or rotary engraver to produce personalized nameplates, keychains, small signs, and ornaments from the sheet. Polycarbonate's durability and UV-stability make finished pieces suitable for long-lasting indoor and moderate outdoor use; the protective film preserves finish until delivery.

Workshop & Classroom Protective Covers Service

Supply custom-cut protective covers, tool guards, sneeze-guards, and instrument lids for schools, makerspaces, dental/medical studios, and small businesses. Promote quick turnaround, shatter-resistance, and the ease of onsite modification (drilling, trimming) for bespoke installations.

Creative

Mini Curved Lantern / LED Diffuser

Heat-bend the 12x12 sheet into a short cylinder or soft curve to form a lightweight lantern body or lamp shade. The clear polycarbonate gives even light diffusion when frosted with light sandblasting or translucent paint; drill small holes for LED wiring and use the shatter‑resistant sheet around kids' rooms or outdoor patios.

Custom Picture-Frame Glazing & Floating Art Panels

Replace glass in frames or create floating acrylic panels for photos, pressed flowers, or layered art. The EasyRuler protective film keeps the surface pristine while cutting and mounting; the sheet is easy to cut to popular sizes (4x6, 5x7, 8x10, 11x14) and safer than glass in homes with children or pets.

Dollhouse and Scale Model Windows

Cut small panes for dollhouse windows, greenhouse roofs, or vehicle windshields — the material bends cleanly for bay windows and thermoforms for curved shapes. UV stabilization prevents yellowing in lit displays and the shatter resistance makes shipping or handling models less risky.

Thermoformed Cosplay Props & Mask Elements

Thermoform sections of the sheet with a heat gun to make visors, helmet face panels, or layered armor accents that are lightweight and impact resistant. The protective film keeps edges scratch-free during shaping; combine with elastic or rivets for wearable pieces.

Layered Shadowbox & Lighted Depth Art

Cut multiple sheets into silhouettes or geometric layers and stack them with spacers to create 3D wall art or illuminated dioramas. Use LED strips between layers for backlit effects — polycarbonate's clarity and clean edges give a professional look without fragile glass.