Features

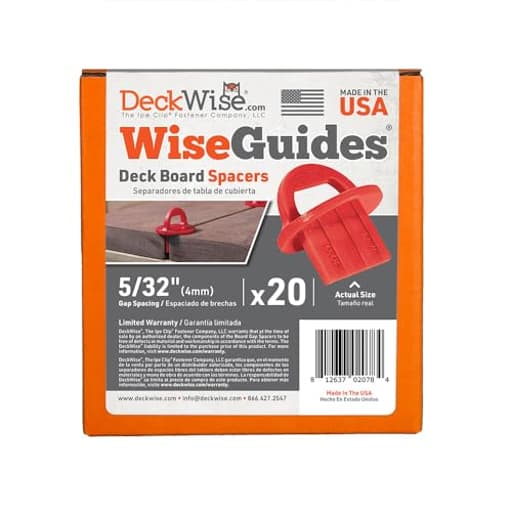

- Provides 5/32" deck spacing

- Special blade design prevents denting and marring of the deck boards

- Bright color-coded design makes finding the right spacer easy

- Each pack includes 20 spacers

Specifications

| Color | Red |

| Size | 5/32 |

Related Tools

These 5/32" deck board spacers ensure consistent 5/32-inch gaps when installing hardwood, pressure-treated, thermal wood, PVC, or composite decking. The spacers feature a blade design that reduces denting and marring, are bright color-coded for easy identification, and are supplied in packs of 20.

DeckWise WiseGuides 5/32" Gap Deck Board Spacer Guide for Hardwood, Pressure Treated Lumber, Thermal Wood, PVC and Composite Decking Alignment Review

Why consistent spacing matters—and how these spacers help

Uniform gaps aren’t just about looks on a deck; they’re about drainage, drying, and long-term stability. After a few deck installs and a handful of repairs, I’ve learned that board-to-board consistency is one of the easiest places to go wrong and the hardest to fix after fasteners are in. That’s where the DeckWise 5/32-inch spacers have earned a permanent spot in my bucket. They’re simple, durable, and—most importantly—repeatable.

Design and build

These are single-size spacers, all set at 5/32 inch and color-coded red. I appreciate the color choice because it’s easy to find them scattered across joists or dropped between boards. Each spacer has a thin “blade” section that sits between the boards and a wider top that keeps it from falling through. The blade isn’t a sharp edge; it has a forgiving profile that doesn’t dent soft woods, which is important when you’re working with pressure-treated decking that’s still a bit wet.

There’s also a built-in handle/loop that makes them easy to place and pull. The loop is comfortable enough to grab with gloves, and there’s a hole if you want to clip a few to a carabiner to keep them together. It’s a thoughtful detail that sounds small until you’re moving down a 16-foot run and constantly repositioning your spacers.

A pack of 20 feels like the right baseline for DIYers, and it’s a workable number even on long runs for a pro crew. I’ve been able to stage multiple boards at a time, which helps catch skew before it compounds.

In use: consistency made easy

Functionally, there’s not much mystery here: the spacers go in, the boards line up, and you fasten. The difference from shop-made shims or random offcuts is how confidently you can keep moving. With these, I can spread five or six along the joist line, set a new board, and know I’ll get the same gap I got on the last row. On large decks, that uniformity matters—slight errors that seem invisible at the start become very visible 12 or 20 feet later.

The 5/32-inch size has been a good middle ground in my climate. It’s generous enough for water and debris to clear, not so wide that small items fall through easily, and it gives wood room to move. On hardwood and composite installs, 5/32 looks clean and functional. If your decking manufacturer specifies a different gap (some composites call for 3/16), follow that. But for many species and systems, 5/32 is right in the pocket.

Two things stood out while using them:

- They don’t mar the board edges. On softer pressure-treated pine, I intentionally pressed the board tight against the spacer to see if it would leave a tooth mark; it didn’t.

- They don’t bind up if you keep your boards reasonably straight. A gentle wiggle or a quick twist of the loop pops them free. When they’re pinched hard—say, if you force a crooked board tight—resist the temptation to reef on the loop with a claw hammer. You can crack the loop if you lever too aggressively. A flat bar against the body of the spacer is safer when things get tight.

Materials I tested

- Pressure-treated lumber: No denting, and the spacers held their dimension even in damp conditions. As the wood dried and shrank, the initial 5/32 gap widened slightly—as expected—so plan your spacing with moisture content in mind.

- Composite decking: Easy workflow, and the spacers didn’t scuff the capped surface. As always, check your brand’s install guide; if they call for a bigger gap, use the appropriate size from the same family.

- Thermally modified wood: Clean edges, no crushing. The stability of thermally modified stock pairs well with a consistent spacer, and the red color made it easy to spot the spacers on darker boards.

- Hardwood (e.g., ipe): I like 5/32 as a starting point here, especially where airflow is limited. The spacers give a crisp, uniform line that complements hardwood’s straight grain.

Workflow tips

- Stage more than you think you need. With 20 spacers, I’ll often lay out four or five boards at once across a 12–16-foot span. This helps me detect a wandering joist or a slight bow early, before it compounds across the run.

- Keep a few in your pouch. The loop makes it easy to clip two or three to a carabiner. I also keep a couple on the rail when I’m working picture frames or stairs where the layout gets tight.

- Clean as you go. Sawdust and chips will exaggerate the gap if they’re trapped against the spacer face. A quick brush or a blast from a blower keeps your spacing true.

- Don’t leave them in too long under load. If a board is fighting you, correct the board first rather than using the spacers as wedges while you muscle fasteners in.

What I like

- Uniformity: Every spacer in the pack measured dead-nuts consistent across multiple installs. The resulting gaps are visually straight and practically effective.

- Surface safety: The blade profile avoids chewing up edges on soft stock.

- Visibility: The red color is easy to spot in sunlight and in the shadows under a deck.

- Pack count: With 20 in the bag, I can work efficiently across long runs without constantly backtracking.

Where they could be better

- Loop durability under prying: The loop is meant for fingers, not for hammer claws. If you routinely yank on stuck spacers with a tool, expect to fatigue a loop or two over time. A slightly beefier loop or a small metal insert would extend their life in rough use.

- Single-size pack: This pack locks you into 5/32. That’s fine if it matches your spec, but you’ll need a different color/size pack for other projects. I don’t mind this, but budget for multiple sets if you build in varied materials and climates.

- Price versus DIY shims: You can absolutely make spacers from scrap. But you’ll spend time making them, they won’t have the same pull loop or top flange, and they’re easier to lose. The time saved and the reliable geometry justify the cost for me.

Durability and maintenance

I’ve left a handful of these in direct sun and heat during long days without any deformation. They brush clean easily; resin and dirt don’t stick to the plastic much. After a few installs, the faces still measure true and the edges haven’t mushroomed. The only wear I’ve induced was from my own misuse—levering one out under high pinch instead of relieving the board first. Store them clipped together and they won’t wander off your site.

Who they’re for

- DIY deck builders who want professional-looking gaps without micromanaging measurements every row.

- Pros who need repeatable results across big decks and want to speed up layout without sacrificing accuracy.

- Anyone working with materials that specify a consistent gap—composite, PVC, thermally modified wood—where inconsistency can void warranties or cause water problems.

If you regularly build outdoor furniture, these will still work, but 5/32 may be wider than you’d like for seating surfaces; consider a narrower size in the same spacer family.

Value

The value here isn’t in the material of the spacer—it’s in the repeatability and speed. A pack of 20 lets you set up long runs, verify alignment at a glance, and keep moving. For me, that translates into straighter lines, fewer corrections, and a cleaner final appearance. Over the course of a full deck, they more than pay for themselves.

Recommendation

I recommend the DeckWise 5/32-inch spacers. They’re well designed, easy to see and handle, gentle on board edges, and consistent across a full pack. The 5/32 gap is a smart general-purpose size for many wood and composite installations, and having 20 in the pack lets you work efficiently across long spans. Just be mindful when removing tightly pinched spacers—use a gentle twist or a flat bar rather than prying hard on the loop—and you’ll get a long service life out of them. If your deck spec calls for a different gap, pick the appropriate size from the same line, but as a go-to for most projects, this 5/32 set is a reliable, time-saving choice.

Project Ideas

Business

Installer Bundle Kit

Create a small productized kit for homeowners/DIYers: 2 packs of WiseGuides spacers + stainless screws, a starter board template, and a one‑page installation cheat sheet. Sell as an 'Achieve Pro Deck Gaps' kit online or at local hardware stores. Emphasize the non-marring blade and color coding to justify a premium over loose spacers.

Decking Workshop & Certification

Run half‑day hands‑on workshops teaching proper deck board alignment, fastening patterns, and finishing. Use WiseGuides during training to show consistent spacing. Charge per seat and offer a discounted spacer pack as part of the ticket price. Upsell certified installers to local homeowners and contractors.

B2B Contractor Packs & Co‑Branding

Offer bulk packs and co‑branded spacer sets to local deck builders and home improvement contractors. Provide branded instruction cards or NFC links to best‑practice videos demonstrating how the blade design reduces marring and speeds installation. Use volume pricing to lock in repeat orders.

Content Funnels — How‑To Videos & Kits

Create short step‑by‑step video content showing quick wins (e.g., how to get perfectly even gaps on composite decking). Drive traffic to an e‑commerce page selling WiseGuides spacers, accessories, and downloadable cut lists. Monetize with affiliate links to deck materials and tools, and offer a paid 'deck planner' PDF or calculator.

Tool Library / Rental Service

Add Wiseguide spacer packs to a local tool‑library or rental toolbox for weekend DIYers who need precision but not long‑term ownership. Rent as part of a 'deck finishing kit' that includes clamps and a tapping block. This captures customers who will later buy materials and recommend your associated services or products.

Creative

Precision Slatted Bench

Build an outdoor bench or coffee table with perfectly even spacing between slats. Use the WiseGuides 5/32" spacers as a reusable jig to maintain uniform gaps across the seat and back. The blade design prevents denting when tapping boards into place on softer woods, and the bright red spacers double as placement guides while you fasten each slat.

Herringbone/Patterned Deck Panels

Create modular herringbone or chevron deck panels with factory‑perfect gaps so they can be assembled like tiles. Use the spacers during assembly to guarantee consistent 5/32" reveals between boards, producing a high‑end look when panels are laid on a porch, balcony, or rooftop. The color-coded spacers make alignment fast when repeating the pattern.

Planter Boxes with Ventilation Gaps

Construct weatherproof planter boxes or raised garden beds that need small, consistent gaps for drainage and airflow. The 5/32" spacers give an attractive, functional reveal between boards. Because the spacer blade won’t mar the boards, you can tighten fasteners without worry and leave a professional finish for plants and outdoor decor.

Deck Lighting Channel Jig

Use the spacers as a simple jig to maintain consistent space for running thin LED strips or micro‑lighting channels between deck boards. The fixed 5/32" gap is ideal for low‑profile lighting; assemble boards over the spacer, install the lighting, then remove spacers to leave an even channel for diffusers and wiring.

Mini Model Decks & Presentation Samples

Make scaled demo panels or client presentation samples that show how different board materials and gap widths look. The pack of 20 spacers is perfect for repeatable models — the bright red guides also act as visual cues during client meetings to demonstrate spacing options and workmanship standards.