Features

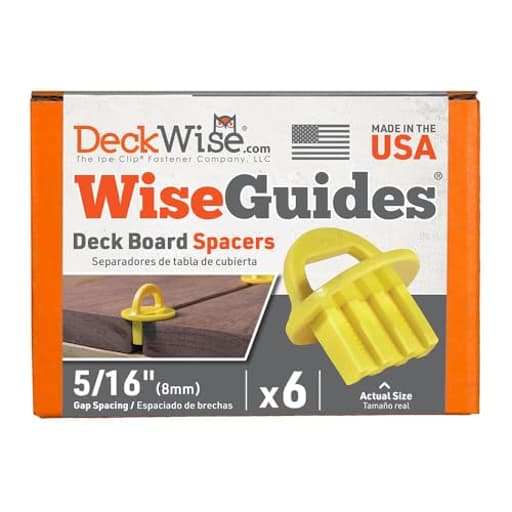

- Provides 5/16" deck spacing

- Special blade design prevents denting and marring of the deck boards

- Bright color-coded design makes finding the right spacer easy

- Each pack includes 6 spacers

Specifications

| Size | 5/16 |

Related Tools

Handheld deck spacers that set a consistent 5/16" gap between boards and are compatible with hardwood, pressure-treated, thermal wood, PVC, and composite decking. The blade design minimizes denting and marring, the bright color makes them easy to locate, and the pack includes six spacers.

DeckWise WiseGuides 5/16" Gap Deck Board Spacer Guide for Hardwood, Pressure Treated Lumber, Thermal Wood, PVC and Composite Decking Alignment Review

Why I reached for these spacers

On any deck build, the straightest lines aren’t the ones you draw—they’re the ones you repeat. Board spacing is a perfect example: get it consistent and the deck looks intentional; miss by even a hair and the eye catches it from across the yard. For a recent project mixing hardwood treads and composite field boards, I used the WiseGuides spacers to set a 5/16-inch gap across the entire run. They promised uniform spacing without bruising the boards, and after a full build, I can say they did exactly that with a few caveats worth knowing.

Design and build

These are simple, purpose-built tools: 5/16-inch spacers with a flat “blade” profile, a finger ring for easy extraction, and a bright color that’s hard to lose in sawdust. The pack includes six, which is enough to get started but not always enough for long runs (more on that later). The edges are slightly relieved so they slide between boards without chewing up fibers, and the plastic formula feels denser and tougher than the throwaway shims you might be tempted to use.

The “blade” shape is the key feature. Instead of a chunky rectangular block, the contact area is narrow with softened corners. That keeps the pressure off the face of the board and reduces dents, especially on softer pressure-treated lumber. It also threads neatly between boards seated with hidden fasteners, which can be a pain point for blockier spacers.

In use: speed and consistency

The strongest compliment I can give these is that I stopped thinking about spacing after the first few rows. On 10- and 12-foot runs, I staged a handful of spacers per joist bay, set the board, tapped everything flush, and drove fasteners. The boards pinched against the spacers, I set my screws or clips, gave a tug on the pull ring, and kept moving. That rhythm is what you want: no fiddling with feeler gauges, no grabbing random nails, and no backtracking to correct a wandering gap.

The 5/16-inch size is a practical choice for a lot of materials. It gives composites and PVC enough breathing room for thermal movement and keeps hardwoods from trapping water between boards. If you’re installing wet pressure-treated lumber, that gap also hedges against swelling in the first season.

I used these with both face screws and hidden fasteners. With clips, the thin blade slides between boards even when the clip is partially seated, so there’s no awkward dance. With face screws, the spacers make it easier to hold a board in place while you get the first fasteners biting, especially when you’re solo.

Accuracy and material compatibility

I checked the actual thickness of several spacers before starting: they were remarkably consistent and didn’t show any molding flash that would keep them from seating fully. Under clamp-like pressure from forcing a slightly crowned board into line, they didn’t deform or spring. That lack of flex is important because a spacer that compresses even a fraction defeats the purpose of using one.

The blade edges didn’t bruise my pressure-treated boards, and they left no scuffs on composite surfaces. On ipe stair treads, the narrow profile kept the spacer from creating shiny rub marks—something I’ve seen with harder, sharper-edged blocks. If you’re working with thermal-modified wood or other brittle species, the eased corners help the spacer find its way without chipping an arris.

Ergonomics and durability

Two small details make a big difference. First, the color. It seems trivial until you drop one off the edge or bury it in sawdust; I rarely lost sight of them, and when I did, spotting them was easy. Second, the pull ring. It gives you a confident grip for extraction even when the boards are pinching hard. I could hook one with a finger or a tool and yank it free without drama.

Durability-wise, they’re tougher than they look. I occasionally had to tap a spacer with a hammer to start a stubborn gap, and a couple of times I pried one out with the claw when the boards had cinched tight after fastening. No cracks, no chips, and no visible wear beyond a few scuffs. After a few weeks in sun and sawdust, they didn’t warp or get brittle. They’re also thick enough that they don’t flex or chatter under load.

Where they fall short

One size only. 5/16 inch is versatile, but it isn’t universal. For kiln-dried hardwood installed in low humidity, 5/16 can look a touch generous. For wet pressure-treated stock that will shrink, it’s a safe bet. The point is: you still need to choose the right gap for your material and climate. These spacers won’t make that decision for you.

Count per pack. Six spacers is fine for short sections, but once you’re staging across longer boards, you’ll want more. I like at least one spacer at each joist for longer runs to maintain alignment while fastening. Plan on buying a second pack if you’re working solo or covering big spans.

Tight quarters. Around posts, at the start of a run against a ledger or wall, or when notching around obstructions, the rectangular blade can be a little chunky. A half-moon or tapered nose would slide into those awkward corners more gracefully. I worked around this by starting the gap with a thinner feeler (a putty knife or a composite shim) and then finishing with the spacer.

Not a board straightener. This is a spacer, not a tool for wrestling twisted or crowned boards. If you’re dealing with wonky lumber, you’ll still want a board bender or a clamp setup. Once you’ve brought a board into line, these spacers lock in the gap, but they won’t do the heavy lifting for you.

Who these are for

- DIY builders who want professional-looking, uniform lines without reinventing the wheel on each board.

- Pros who need a durable set of spacers that won’t mar decking, especially when moving between materials (PT, hardwoods, composites, PVC).

- Anyone using hidden fasteners. The blade profile and pull ring make life easier with clip systems.

If you need multiple gap options on a single project, consider pairing these with a different size spacer set. And if your deck is full of unruly boards, add a board straightening tool to your kit; the spacers will complement it well.

Practical tips from the build

- Stage more than you think. Lay out spacers at each joist for long boards so gaps don’t wander as you fasten.

- Seat, then set. Slide spacers in, tap the board home, then fasten. Pull the spacers after the fasteners bite.

- Protect soft faces. On softer lumber, start the insertion by wiggling the spacer in rather than hammering it to avoid surface dents.

- Keep a thin starter. A putty knife or paint stirrer helps open tight spots; swap in the spacer once you’ve established the gap.

- Match gap to material. 5/16 works well for many composites and wet PT. For kiln-dried hardwood in arid conditions, confirm your decking manufacturer’s spacing guidance.

Final recommendation

I recommend the WiseGuides spacers. They’re accurate, tough, and designed with the right details—namely the blade profile and pull ring—that make day-to-day deck building smoother. The bright color saves time, the plastic is kinder to board edges than metal shims or improvised nails, and the consistent 5/16-inch gap delivers clean, repeatable lines. You’ll likely want more than one pack for longer runs, and you’ll still need other tools for straightening stubborn boards, but as a dedicated spacing solution, these strike a smart balance of simplicity and performance.

Project Ideas

Business

Small Deck Installation Service

Start a boutique deck installation business specializing in precise, high-quality spacing using WiseGuides. Market the consistent 5/16 inch gap as a quality differentiator that improves drainage and aesthetics. Use photos showing the bright spacers in action to highlight craftsmanship on your website and social media.

Preassembled Deck Panel Product

Fabricate and sell preassembled deck panels (e.g., 4x8 sections) with factory-controlled spacing using the spacers during assembly. Panels can be marketed to DIY homeowners and contractors as time-saving drop-in sections. The non-marring blade feature lets you deliver finished-looking panels without cosmetic damage.

Workshops & Training Classes

Offer hands-on workshops teaching DIYers and contractors proper decking techniques, including consistent spacing and fastener placement using WiseGuides. Charge per participant and sell spacer packs on-site. Demonstrate how spacing affects drainage and longevity to position the tool as essential.

Tool + Material Kits for DIYers

Bundle a small number of WiseGuides with cut-to-size decking boards, fasteners, and a plan (e.g., bench, planter, coffee table) to sell as a DIY kit online or at local hardware stores. The bright spacer included makes assembly faster and reduces errors, increasing customer satisfaction and lowering returns.

Content & Affiliate Channel

Create a content channel (short videos, how-to guides, blog posts) focused on deck building tips using the spacer as a recurring tool in demos. Monetize through affiliate links to the WiseGuides, tool rentals, sponsorships from material suppliers, or selling downloadable plans that emphasize precise spacing and finish.

Creative

Deck-Style Coffee Table

Build a coffee table top from deck boards using the WiseGuides to keep consistent 5/16 inch gaps. The spacer guarantees a weathered, airy look and the special blade prevents marring on hardwood or composite boards. Use the bright spacers to speed layout, glue or screw from below, then finish with outdoor oil for a porch-ready piece.

Slatted Headboard or Room Divider

Create a modern slatted headboard or freestanding room divider made of pressure-treated or thermal wood. The spacers keep even slats for a precise visual rhythm; their non-marring design protects the boards during clamping and assembly. The consistent gap makes it easy to add backlighting or fabric panels behind the slats for added effect.

Garden Bed & Planter Cladding

Use composite or treated decking boards to clad raised garden beds and planters. The 5/16 inch spacing allows for drainage and breathability while giving a finished deck-like appearance. The blades prevent dents during fastener placement, and the bright color speeds repetitive placement when building multiple planters.

Outdoor Wall Art (Modular Slat Panels)

Cut deck boards into panels and assemble modular slat art for patios or fences. The spacers ensure uniform gaps across panels so modules can be mixed and matched. Because the tool is compatible with PVC and composite, you can make low-maintenance outdoor art that resists weathering.

Deck-Style Cabinet & Shelf Fronts

Apply deck-style slatted fronts to cabinets, bathroom vanities, or shelving for a coastal/industrial look. Use the WiseGuides to keep exact 5/16 inch reveals between slats so doors and drawer fronts line up perfectly. The non-marring blade preserves finish while you shim and screw from behind.