Features

- One-handed trigger operation

- 300 lb (135 kg) clamping force

- 3-1/4 in (80 mm) throat depth

- Converts to spreader with quick-change button

- Reinforced nylon body

- Heat-treated steel I-beam bar

- Removable non-marring jaw pads

- Quick release mechanism

- Safety stop

- Spreading function

Specifications

| Clamping Force | 300 lb (135 kg) |

| Average Clamping Force (Kg) | 135 |

| Sustained Clamping Force (Kg) | 135 |

| Maximum Jaw Opening / Clamping Capacity | 12 in (320 mm) |

| Spreading Capacity | 480 mm |

| Bar Length | 300 mm |

| Bar Material | Black oxide carbon steel I‑beam |

| Bar Thickness | 5 mm |

| Body Material | Reinforced nylon (plastic) |

| Throat Depth | 3-1/4 in (80 mm) |

| Jaw Width | 40 mm |

| Jaw Depth | 50 mm |

| Jaw Pads | Non‑marring, removable |

| Handle Type | Trigger |

| Handle Material | Plastic |

| Quick Release Mechanism | Yes |

| Safety Stop | Yes |

| Number Of Pieces | 1 |

| Product Weight | 600 g (0.6 kg) |

| Product Dimensions (W/O Packaging) | 490 x 240 x 40 mm |

| Packaging | Hang tag |

| Warranty | 1 Year Limited Warranty |

Related Articles

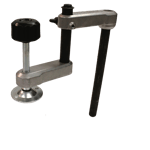

12-inch one-handed trigger clamp with a reinforced nylon body and a heat-treated steel I‑beam bar. Provides up to 300 lb (135 kg) of clamping force, a 3‑1/4 in (80 mm) throat depth, and converts to a spreader via a quick-change button. Removable non‑marring jaw pads help protect work surfaces.

DeWalt 12 in. Large Trigger Clamp Review

What stood out in day-to-day use

This 12-inch trigger clamp has become one of those reach-for-it-first tools in my shop. It’s light enough to use overhead or at arm’s length, strong enough for most woodworking and remodeling tasks, and the one‑handed trigger is genuinely practical when the other hand is holding a part in place. Across cabinet installs, trim work, and small glue-ups, it’s held pressure without creeping and made solo work noticeably easier.

DeWalt rates it at 300 lb of clamping force, and while I’m not measuring that on every squeeze, the holding power feels appropriately stout. I’ve used it to pinch stubborn face frames into alignment, to hold a jig against a sheet, and to immobilize PVC while cutting—no slipping, no sudden release. The 0.6 kg weight also strikes a nice balance: substantial enough to feel planted, but not fatiguing.

Build and ergonomics

The reinforced nylon body surrounds a heat-treated, black-oxide steel I‑beam bar (5 mm thick). The bar doesn’t twist under load, which helps the jaws stay parallel and keeps pressure even. The body casting has enough stiffness that flex is minimal unless you’re at the very end of the travel and cranking hard.

Ergonomically, the main trigger is well-shaped and easy to modulate. Each squeeze advances the jaw a meaningful amount—roughly three-quarters of an inch in my experience—so you don’t need endless clicks to take up slack. The quick-release lever is positioned where your index finger naturally lands. Under heavy load, it can feel a bit stiff; feathering the main trigger while touching the release helps the jaw back off smoothly. With gloves on, I’d prefer a little more texture on the release, but it’s a minor gripe.

The removable, non‑marring jaw pads are generous. On painted trim, hardwood veneers, and prefinished cabinet parts, they’ve prevented marks. On very soft woods, you can still compress the surface if you overtighten, so a scrap caul is still a good idea for sensitive faces.

Capacity and reach

You get a 12-inch max opening (about 320 mm) and a 3‑1/4 inch throat depth. That reach is fine for edge work, face frames, light panel glue-ups, and general assembly. It’s not the clamp you pick for deep-case joinery or wide tabletops—you’ll still want F‑style or parallel clamps for those. The 40 mm jaw width and 50 mm jaw depth feel well-matched to the bar size; there’s enough jaw area to distribute pressure without being too bulky in tight quarters.

Spreader mode that’s actually useful

A quick-change button flips the movable jaw, converting it to a spreader with roughly 480 mm of capacity. I used spreading mode for installing bifold door hardware and nudging jambs into square. It applies pressure smoothly without chattering, and the safety stop keeps the jaw from sliding off the bar near full extension. For anyone who does remodeling or door and window work, this feature earns its keep.

Holding power and control

Where this clamp shines is controlled pressure. The mechanism builds force progressively, and once you’re tight, it stays tight. I’ve left overnight glue-ups with two of these on edge banding and found no shift the next morning. The I‑beam bar resists twist better than the flat bars on many budget quick-grips, which helps prevent that “walk-off” you see when the jaw starts to rotate under load.

The quick-release doesn’t dump the load abruptly, which is good for delicate setups. That said, under high tension the release does take a deliberate pull. A tiny drop of dry lube on the bar and keeping dust off the pawl makes the action consistently smooth.

Durability and maintenance

Reinforced nylon is a smart choice here: light, stiff, and it shrugs off normal shop abuse. Still, it’s not a pry bar. If you reef on the handle to twist parts into submission, or if the clamp takes a hard drop onto the corner of the body, you can overstress the housing. Treat it like a precision clamping tool and it’ll last.

The pads are consumables in any shop; these pop off easily and spares are inexpensive. The black-oxide on the bar resists rust, but if you’re working in a humid space, wiping it down occasionally and avoiding oily overspray on the pads will keep the mechanism positive and your work clean. The safety stop has kept the moving jaw from launching off the end of the bar more than once—nice detail.

After months of use, mine shows the expected scuffs and a few dents on the pad faces, but the ratchet remains crisp and the bar straight. The 1‑year limited warranty is there, though I doubt you’ll need it unless something manufacturing-related surfaces early on.

Where it’s at its best

- Solo installs: Holding trim, aligning face frames, tacking fixtures while you drive fasteners.

- Quick jigs and fixtures: Clamping a fence to a miter saw stand, a stop block to a bench, or a guide to sheet goods.

- Light-to-medium glue-ups: Edge banding, small panels, drawer boxes, mitered moldings, and repairs where you want speed and control.

- On finished surfaces: The pads protect paint and veneer when used with reasonable force.

Where it falls short

- Depth and span: A 3‑1/4 inch throat won’t reach into case interiors, and 12 inches of opening is limiting for larger assemblies.

- Release feel under load: Functional but can be tight. Technique helps; a little maintenance helps more.

- Pad bulk: The wide pads can interfere in tight joinery; removing a pad or using a narrower clamp can solve it.

- Not a breaker bar: Over-torquing at the very end of the travel or using the clamp to lever parts can risk cracking the housing.

If you routinely do large panel glue-ups or need high, perfectly parallel pressure across wide faces, a set of parallel-jaw clamps or pipe clamps will outperform this style. Think of this as a fast, precise “third hand,” not a substitute for the big iron.

Value

It’s priced at the premium end of trigger clamps, and you feel that in the fit, finish, and bar rigidity. If you need a dozen clamps for occasional use, budget models will hold parts together. If you want something you can rely on for daily tasks, with better bite and less flex, the extra cost makes sense—especially if you’re working solo and speed matters. The ability to replace pads extends its service life and softens the long-term cost.

Tips for best results

- Keep the bar clean; a quick wipe prevents grit from roughing up the pawl.

- Use cauls on softwoods and delicate finishes to spread load.

- Feather the main trigger while pulling the release to ease tension smoothly.

- Don’t use the clamp as a spreader to “jack” heavy assemblies apart—stay within its intended load.

Bottom line and recommendation

I recommend this 12-inch trigger clamp for anyone who needs a dependable, one-handed clamp for woodworking, remodeling, and general shop tasks. It delivers real holding power, a robust bar that resists flex, and a spreader mode that’s more than a checkbox feature. The ergonomics are solid, the pads protect finished work, and the overall package feels purpose-built for the jobs most of us do every day.

It’s not the right tool for deep-reach or heavy, wide glue-ups, and the release can feel stiff under high load. It also costs more than entry-level options. But measured against its performance, speed, and durability, it earns a spot on the rack. If you’re building out a core set of clamps, start with a pair of these 12-inch units and add size variety as needed—you’ll use them constantly and wonder how you worked without them.

Project Ideas

Business

Mobile Picture Framing Side Hustle

Offer in‑home frame assembly and miter glue‑ups. Use the clamps to draw corners tight without marring, and the spreader to fine‑tune frame squareness. Upsell custom matting and hardware; low overhead and fast turnaround make it profitable.

Small-Batch Cutting Boards & Decor

Produce edge‑grain boards, serving trays, and trivets. The clamps handle panel glue‑ups quickly with consistent pressure and clean seams. Sell via Etsy, markets, and wholesale to local boutiques; add engraving as a premium option.

Chair and Furniture Re‑Glue Service

Specialize in loose chair joints and split rails. The clamp’s controlled, one‑handed pressure lets you re‑glue and align parts on-site. Pads protect finishes; the spreader function helps re‑seat stretchers. Offer flat-rate per joint and pickup/delivery.

Cabinet & Trim Install Alignment

Serve contractors by aligning face frames, fillers, and scribe strips. Clamp parts flush while fastening; use spreader mode as a ‘third hand’ to brace panels or widen reveals. Bill per hour or per install; speed and finish quality are the value props.

Pop-Up Workshops + Tool Sales

Host beginner classes on glue‑ups, frames, or cutting boards. Provide clamps for each station; demo proper clamping pressure and caul use. Monetize through class fees, project kits, and post‑class sales of clamps and materials via affiliate or retail markup.

Creative

Laminated Cutting Board Glue-Up

Rip maple/walnut strips, apply glue, and use 2–4 clamps across the panel. The 300 lb force and 3-1/4 in throat depth keep edges flush with cauls, while the non‑marring pads protect the grain. Quick release speeds up staging; flip to spreader mode to pre‑tension cauls that eliminate bow.

DIY Bookbinding/Print Press

Make two MDF platens and sandwich your books, lino prints, or cyanotypes. Use a pair of clamps to deliver even pressure over the stack. The I‑beam bar resists flex, pads won’t imprint the paper, and one‑handed triggers let you set pressure gradually without shifting the work.

Accurate Picture Frame Clamping Jig

Cut 45° miters, add corner blocks, and use the clamp to pull opposite corners tight. The quick‑change button lets you switch one clamp to spreader to gently push inside corners for perfect alignment. Pads prevent denting softwoods and the safety stop keeps pressure controlled.

Canvas Stretching and Frame Tensioning

Assemble stretcher bars square, then convert the clamp to spreader mode to gently expand the frame for taut canvas. Switch back to clamping to hold canvas and battens while you staple. The 12 in opening covers small/medium frames and pads avoid marring primed surfaces.

Steam-Bent/Laminated Tray Handle

Create a bending form, laminate thin strips with glue, and clamp them around the form. The 300 lb clamping force ensures tight laminations; the 3‑1/4 in throat reaches over the curve. Use several clamps along the bend; pads prevent compression marks on the outer fibers.