Features

- 3.5 joules of impact energy for drilling in concrete

- Anti-rotation E-CLUTCH system that stops bit rotation in bind-up situations

- SHOCKS Active Vibration Control system to reduce vibration at the handles

- Brushless motor and durable gearbox for improved runtime and efficiency

- Rotating dial to select application mode: Drill, Hammer Drill, or Chip

- Dust extraction ready (compatible with on-board extractor for OSHA Table 1 compliance)

- Balanced, L-shape design intended for overhead and tight-space applications

- Includes 360° side handle and depth rod (tool only — battery/charger not included)

Specifications

| Battery Type | Lithium Ion |

| Battery Voltage | 20 V |

| Battery/Charger | Sold separately |

| Power Source | Battery |

| Rated Power | 300 W |

| Impact Energy | 3.5 J |

| Chuck Type | SDS+ |

| Maximum Chuck Size | 1-1/8 in |

| No Load Speed | 1000 RPM |

| Maximum Bpm | 4480 |

| Operation Modes | Drill; Hammer Drill; Rotary hammer (chip) |

| Variable Speed | Yes |

| Rotation Control (Anti Rotation) | Yes (E-CLUTCH) |

| Vibration Control | Yes (SHOCKS Active Vibration Control) |

| Tool Weight | 8.21 lb |

| Tool Length | 15.63 in |

| Tool Height | 10.63 in |

| Tool Width | 4 in |

| Maximum Capacity Concrete | 0.875 in |

| Included Accessories | 360° side handle; depth rod |

| Warranty | 3-year limited (1 year free service, 90 days satisfaction guarantee) |

| Osha Compliance Note | Can achieve OSHA Table 1 compliance when used with compatible on-board extractor |

Related Tools

Related Articles

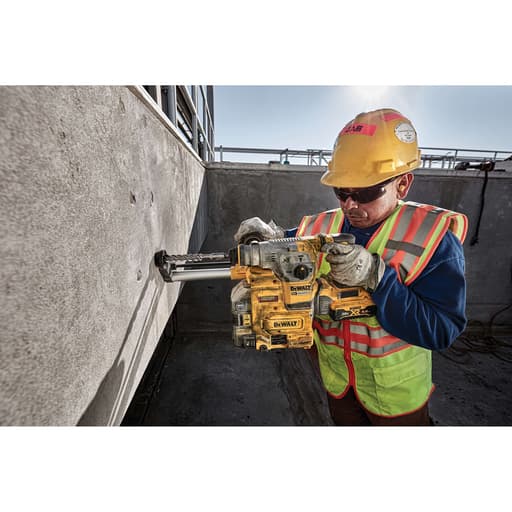

L-shape cordless rotary hammer with a brushless motor and a German-engineered gearbox. Provides 3.5 joules of impact energy for drilling in concrete and large-diameter hole drilling. The tool has vibration reduction at the handles, an anti-rotation (e-clutch) system for bind-up protection, a mode selector (drill, hammer drill, chip), and is dust-extraction ready. Battery and charger sold separately.

DeWalt 20V MAX XR Brushless Cordless 1-1/8 in SDS PLUS L-Shape Rotary Hammer (Tool Only) Review

Why I reached for this rotary hammer

On jobs that live squarely in SDS‑Plus territory—setting anchors in cured slab, drilling through block, or chipping away stubborn tile—I want a cordless rotary hammer that hits hard, manages vibration, and doesn’t yank my wrist when a bit grabs. DeWalt’s DCH293 checks those boxes. After several weeks of using it on a mix of anchor installs and light demo, it’s become the mid‑size rotary hammer I toss in the truck when I want corded‑like pace without the cord.

Build and design

The DCH293 has the familiar L‑shape layout with the motor positioned behind the gearbox. That architecture tends to balance well, and it does here. Bare tool weight lands just over 8 lb; add a 5Ah or 8Ah pack and you’re in the 9–10 lb range. It feels compact for its class, and the footprint plays nicely on ladders, in mechanical rooms, and overhead.

Fit and finish are strong: a metal front end where you want it, a positive‑engagement SDS‑Plus chuck, and a mode dial that clicks firmly through drill, hammer‑drill, and chip. The 360° side handle tightens securely and doesn’t creep under load. The depth rod is basic but useful for repetitive anchor work.

Power and drilling performance

Impact energy is rated at 3.5 joules, which puts it in the sweet spot for a do‑most SDS‑Plus rotary hammer. In practice, the tool chews through common anchor sizes quickly:

- 3/8 in drop‑ins: quick, repeatable holes in cured 4,000 psi slab

- 1/2 in wedge anchors: no drama, clean round holes

- 5/8 in anchors: a steady, controlled pace

- Up to 7/8 in: workable when needed, but this is the upper end of where I’d run it all day

Trigger modulation is excellent. The variable speed lets me start holes precisely without skating, and once the flutes engage, the hammering takes over and maintains consistent progress. I ran a mix of two‑cutter and four‑cutter bits; the tool had no trouble keeping either type clearing dust and staying straight.

If you live in very hard aggregate or routinely drill near the top of the SDS‑Plus range, a corded unit or an SDS‑Max hammer is still faster. But for general concrete, CMU, and brick, the DCH293 delivers productivity that feels on par with many corded midsize hammers, minus the extension cord gymnastics.

Vibration and control

Vibration control is where this tool separates itself. DeWalt’s SHOCKS system noticeably calms the buzz at the handles. After a day of drilling a couple hundred anchor holes, I felt less hand fatigue than I’m used to with older designs. That matters when the tool is part of your weekly routine.

The electronic anti‑rotation clutch (E‑CLUTCH) is another standout. If the bit binds in rebar or a chip wedges the flutes, the motor stops quickly instead of wrenching your wrist. I intentionally jammed a bit in a blow‑out to see how it behaved; the clutch cut power fast, and the side handle didn’t try to spin me off the ladder. It’s an important safety net when working in unknown concrete and a real benefit for overhead work.

Chipping and versatility

In chip‑only mode, the DCH293 is effective for light demo: removing tile and thinset, chasing shallow channels for conduit, trimming form lines, and tidying blow‑outs around holes. It’s not an SDS‑Max breaker—and it’s not meant to be—so if you’re taking out thick mortar beds or heavy sections of concrete, you’ll want a larger hammer. But for punch‑list chiseling and prep work, the tool is efficient and easy to control.

The mode selector is simple and positive; you can switch from drilling to chipping mid‑task without hunting for a tiny button. There’s enough rotational play in the chisel positioning to align a flat where you want it before you start hammering.

Runtime and battery choices

Runtime tracks with bit size and material, as you’d expect. As a general guide from my use:

- With a 5Ah pack, I can typically drill 40–60 holes at 3/8 in x 2 in in cured concrete before I see a significant drop.

- A 6Ah or 8Ah pack extends that into the 70–100 hole range for the same size, and the larger packs keep hammer energy more consistent late in the discharge curve.

If you’re drilling 1/2–5/8 in holes all day, plan on higher‑capacity packs and a charger nearby. The tool happily runs on the standard 20V MAX XR batteries; stepping up in capacity increases runtime but also adds weight. I prefer 6Ah as the balance point for most anchor work and move to 8Ah when I know I’ll be on the hammer for extended periods.

The brushless motor helps with efficiency and heat management. Even in summer attic temps, the tool stayed composed, and I didn’t trigger thermal shutdowns.

Dust collection and OSHA Table 1

Dust extraction is one of this model’s strengths. It’s ready for an on‑board extractor that integrates directly with the front end, making it straightforward to hit OSHA Table 1 for many SDS‑Plus drilling tasks without wrangling a hose. I tested it with DeWalt’s compatible on‑board unit and appreciated the balanced feel—heavier than bare, but still compact and manageable on a ladder. Fine dust capture was solid, and the depth stop integration is handy for repeat holes.

If you prefer a full‑size HEPA vac, the tool plays well with a whip hose and sleeve; the side handle leaves room to route a nozzle near the bit without obstructing your grip.

Ergonomics and user experience

- Balance: The L‑shape keeps the mass close to your wrist, which pays off overhead and on vertical surfaces.

- Trigger and lock‑off: The trigger is progressive and predictable, and the lock‑off is placed where you won’t bump it accidentally.

- Bit changes: The SDS‑Plus chuck snaps bits in and out smoothly even with dusty shanks. A quick wipe keeps it feeling new.

- Visibility: The nose is trim enough that aligning marks on concrete is easy. I wouldn’t say it’s laser‑precise, but I rarely needed to start pilot dents.

Noise is typical for the class—hearing protection is a must. The vibration character is muted and lower‑frequency compared to harsher hammers, which makes longer sessions more tolerable.

Durability and maintenance

Between the brushless motor and a robust, metal‑forward gearbox, this hammer feels built to last. I prefer to blow out the chuck with compressed air and add a dab of SDS‑Plus bit grease before longer sessions; that keeps the nose from running hot and extends seal life. After some gritty, dusty work, the selector and trigger remained crisp, with no play developing in the side handle collar.

DeWalt’s warranty coverage (3‑year limited, 1‑year service, 90‑day satisfaction) is in line with the category. It’s a tool I’d expect to keep in rotation for years with basic care.

What I’d change

- Include a case: The tool‑only configuration keeps initial cost down, but a molded case would protect the nose and keep the side handle and depth rod together between jobs.

- LED placement: An onboard light would be nice for deep cabinets and low‑light mechanical rooms. Not a deal‑breaker, but I missed it a couple of times.

- Top‑end drilling: It can run larger SDS‑Plus bits, but if your daily work sits at 7/8 in and up, you’ll want more hammer mass or to step into SDS‑Max.

Who it’s for

- Trades drilling frequent 3/8–5/8 in anchors in concrete and CMU

- Remodelers handling tile demo, small chases, and occasional slab work

- Facility teams needing a compact, cordless hammer that’s dust‑compliant and easy to carry site‑to‑site

If your work is mostly light tap‑con drilling in masonry, a smaller rotary hammer may be more nimble. If you break out 1‑1/4 in bits and bushing tools regularly, you’re beyond what SDS‑Plus is meant for.

Recommendation

I recommend the DCH293 as a primary SDS‑Plus rotary hammer for anyone who wants strong cordless performance with excellent control and reduced vibration. It hits above its weight in power, stays comfortable over long sessions, and the E‑CLUTCH adds meaningful safety. Pair it with a couple of higher‑capacity packs and the on‑board extractor, and you have a job‑site‑ready drilling setup that keeps pace with corded tools for the bulk of SDS‑Plus tasks. It’s not the right pick for heavy chipping or routine 1‑in‑plus boring, but for the anchor‑drilling, light‑demo, and overhead work most of us do, it’s a dependable, efficient choice.

Project Ideas

Business

Dustless Masonry Anchor Installation Service

Offer a mobile, OSHA Table 1-compliant service installing anchors for TVs, handrails, awnings, racking, and equipment into concrete/brick. Use the rotary hammer with on-board dust extraction and depth control for uniform embedment. Charge per anchor or per visit; upsell epoxy anchoring and pull-test documentation for commercial clients.

Low-Dust Drilling for MEP Trades

Partner with electricians, plumbers, and HVAC contractors to drill precise holes for conduit clips, pipe hangers, strut, and supports in masonry. Provide fast, clean, depth-controlled holes with minimal dust migration in finished spaces. Offer per-hole pricing tiers and rapid-response scheduling for change orders.

Tile, Thinset, and Surface Prep Chipping

Use chip mode with wide chisels to remove tile, thinset, and old adhesive from concrete slabs and walls ahead of new finishes. SHOCKS vibration control reduces operator fatigue on larger areas. Price by square foot and offer add-ons like crack-chase and patch, and dust containment with HEPA vacs.

Masonry Cable/Conduit Chase and Retrofits

Create clean chases and recesses in brick/concrete for low-voltage lines, exterior lighting, cameras, and EVSE conduit. Hammer-drill pilot holes and chip shallow channels, then backfill with tinted mortar for a near-invisible retrofit. Market to smart-home installers and storefronts needing discreet wiring.

Public Art, Signage, and Exhibit Mounting

Specialize in mounting sculptures, murals, and signage into masonry with wedge/epoxy anchors, including recessing plates in chip mode for flush installs. Provide site surveys, layout, load-rated hardware, and optional pull tests. The anti-rotation clutch improves safety when drilling near rebar or in hard aggregate.

Creative

Carved Concrete Relief Mural with LED Inlays

Use chip mode to sculpt shallow reliefs on a block or poured-concrete wall, then hammer-drill clean channels for low-voltage LED strips and anchors for standoffs. The depth rod helps maintain consistent recess depth; SHOCKS vibration control reduces fatigue during long sessions. Pair with dust extraction for indoor work and finish with tinted mortar/grout to accent the carved textures.

Feather-and-Wedge Stone Splitting for Benches & Planters

Drill a series of evenly spaced holes along a split line in landscaping stone or thick pavers, then use feathers and wedges to cleanly split pieces for custom benches, edging, or planter walls. Follow up with chip mode to texture edges and create drip grooves. The 3.5 J impact energy speeds hole rows; the L-shape balances well on irregular stone.

Industrial Pipe Shelving on Brick

Design and mount heavy-duty pipe-and-flange shelves on brick or concrete walls. Hammer-drill precise anchor holes, using the depth rod to avoid overdrilling and the E-CLUTCH for safety in hard mortar joints. Finish with reclaimed wood shelves; black pipe and raw anchors give an industrial aesthetic.

Garden Rill and Wall Fountain

Chip shallow channels (rills) into cast concrete or large pavers for a recirculating water feature, and drill pass-throughs for tubing and stainless anchors for spouts. The mode selector lets you switch from chiseling to drilling for clean mounting points. Dust extraction keeps slurry and dust under control during dry cuts.

Overhead Hangboard/Training Rig Mount

Install a climber’s hangboard or pull-up rig into concrete or CMU with properly sized wedge or epoxy anchors. The balanced L-shape design and vibration control make overhead hammer drilling more manageable, while the E-CLUTCH offers bind-up protection when hitting rebar or hard aggregate.