Features

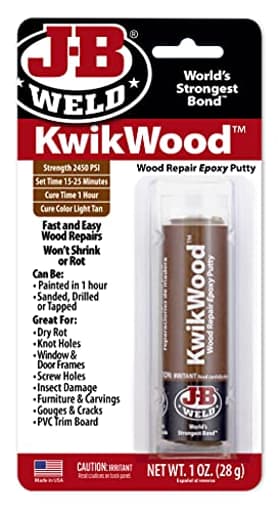

- J-B WELD KWIKWOOD: A hand mixable two part epoxy putty stick that is formulated to repair and rebuild wood. J-B Weld KwikWood is designed for all wood household DIY repairs!

- CURE AND SET TIME: After kneading the two part formula together by hand, KwikWood takes 15-25 minutes to set and cures in 1 hour. J-B Weld KwikWood set and cure color is a light tan.

- PRODUCT FEATURES AND STRENGTH: J-B Weld KwikWood has lap shear strength of 900 PSI. KwikWood will not shrink or rot and can be stained, molded, tapped, drilled, sanded and shaped.

- APPLICATIONS: Window/Door Hinge Repairs, Dry Rot Repairs, Gouges and cracks in furniture, knot hole repairs, gap fillers and more!

- DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

Specifications

| Color | Tan |

| Size | 3.5 inch |

| Unit Count | 1 |

Related Tools

A hand-mixable two-part epoxy putty stick formulated to repair and rebuild wood, suitable for filling gaps, repairing gouges, knot holes, dry rot, and hinge areas. It sets in 15–25 minutes and cures in about 1 hour to a light tan color, has a lap shear strength of 900 psi, and can be molded, stained, tapped, drilled, sanded, and shaped without shrinking or rotting.

J-B Weld Tan KwikWood Wood Repair Epoxy Putty, 1 oz. Stick Review

What it is and where it fits

KwikWood is a hand-mix epoxy putty designed specifically for repairing and rebuilding wood. I reach for it when a project needs more than a traditional water-based filler—things like rebuilding a missing corner, packing out a hinge mortise that’s been over-chiseled, fixing stripped screw holes, or stabilizing punky areas after dry rot removal. It’s a two-part stick you cut, knead, and press into place. It sets in about 15–25 minutes and cures in roughly an hour to a dense, light tan that machines very much like hardwood.

This isn’t a substitute for a proper long-grain glue joint in structural carpentry, and it’s not a beauty product for clear-finished showpieces. It’s a problem-solver for voids, gaps, and damaged areas where you need something that bonds, holds shape, and stays put under load.

Mix, working time, and handling

The mixing process is straightforward: slice off what you need, knead until the color is uniform, and you’re ready. I recommend nitrile gloves; like most epoxies, the amine hardener can be irritating. The working time is short—call it 5–10 minutes of comfortable shaping before it starts to firm up—so I prefer to work in small batches. The putty consistency is excellent: it doesn’t slump, it feathers well at the edges, and you can press it deeply into voids without it sagging back out.

Surface prep matters. I get the best results by:

- Removing loose fibers and all unsound wood

- Lightly undercutting the edges of the repair so the putty has a mechanical lock

- Wiping dust away (a quick pass with denatured alcohol helps)

- Lightly scuffing glossy finishes in the repair area

If you’re filling punky wood from dry rot, consolidate first (epoxy consolidant or penetrating finish) and let it flash off. KwikWood bonds better to firm fibers.

Strength and stability

Once cured, KwikWood is hard. J-B Weld lists a lap shear strength of 900 psi, which tracks with my experience: it’s more than strong enough for hinge screw pockets, doorjamb blowouts, furniture edges, cabinet frames, and even areas that see torsion like chair rungs. I’ve packed out stripped hinge holes on a frequently used entry door and re-drilled after cure; the new screws bite cleanly and hold. I’ve also rebuilt a chipped table edge and a damaged window stool nose where I needed crisp, resilient corners. It doesn’t shrink, it doesn’t crumble, and it takes abuse better than any wood filler I’ve used.

That said, this is still a filler/repair medium, not a structural adhesive designed to replace long-grain wood glue. For high-load repairs (say, a garage door reinforcement bar or a handrail bracket on questionable substrate), I’ll combine approaches: pack the void with KwikWood, let it cure completely, then pre-drill and use a longer fastener into sound wood or add a hardwood dowel or threaded insert. Used that way, the repairs are rock solid.

Sanding, shaping, and machining

KwikWood starts to machine nicely at the one-hour mark, sometimes a bit sooner in warm conditions. It sands about like a dense hardwood—think maple rather than pine—and it handles files and rasps well for dialing in profiles. I’ve cut clean chamfers with a block plane after leveling with a sanding block, and I’ve drilled precise pilot holes without chip-out. It also taps nicely; I’ve cut threads for small machine screws where I needed a metal fastener in a wood repair and it held surprisingly well.

My favorite trick is to rough-shape the repair just before full set with a plastic putty knife or a shop-made contour scraper. Because the working time is short, doing most of the shaping in that window cuts sanding time in half.

Color and finishing

Out of the stick, the cured color is a light tan. Painted finishes are easy—primer and paint stick without issue. Staining is more nuanced. KwikWood can accept color, but it doesn’t behave like porous wood. Oil and gel stains tend to sit on the surface and don’t darken it much, so color matching with stain alone is hit-or-miss. I’ve had the most success with:

- Tinting the mixed putty with epoxy-safe pigments before application

- Using dye-based toners or shellac-based touch-up to color the cured repair

- Finishing with paint or opaque lacquer for invisible results

If your project demands a perfect stain match on a clear-finished surface, a dutchman patch in real wood is still the gold standard. For everything painted—or for tinted touch-ups—KwikWood blends very well.

Adhesion and environmental considerations

Bonding is excellent on clean, sound wood, and it sticks fine to previously painted surfaces that are scuffed. Outdoors, it holds up well if you protect it from UV with paint or varnish. Epoxies don’t like prolonged direct sunlight; they’ll chalk over time if left bare. I’ve used it on exterior trim repairs and window sills with good longevity after primer and topcoat. It doesn’t rot or shrink, so you don’t get those telltale halos that some fillers develop as the seasons change.

Temperature affects cure speed—warmer is faster, colder is slower. In cool shops, I’ll warm the stick slightly in my pocket and give it a little more cure time before machining.

Common use cases that shine

- Stripped screw holes in jambs and cabinets: Pack, cure, and re-drill. For high-stress hinges, add longer screws into framing.

- Rebuilding edges and corners: Table edges, stair nosings, shelf fronts. Easy to shape, and it holds crisp profiles.

- Knot holes and voids: Fill, sand flush, and paint. Great for shop furniture and utility-grade lumber upgrades.

- Dry rot repairs after consolidation: Carve back to sound wood, pack, and overcoat with a protective finish.

- Appliance and furniture fixes: Cabinet shelves, chair rails, and drawer fronts where a chunk has broken out.

In each of these, the putty format beats liquid epoxy for ease of placement and shape control.

Limitations and gotchas

- Short working time: Fantastic for quick fixes, but you need to be organized. Mix small amounts and stage complex profiles in layers.

- Stain matching: Manage expectations. It’s not porous wood; plan on pigment, toner, or paint.

- Shelf life: Like most epoxy putties, fresh is best. Old sticks can partially cure or never fully harden. If a stick feels dry, crumbly, or has an off smell beyond typical epoxy, replace it.

- Depth and heat: Very thick masses can exotherm and cure faster in the core. For deep voids, I sometimes fill in two lifts to control heat and ensure full cure.

None of these are dealbreakers, but they’re worth knowing so you can set yourself up for success.

Practical tips for better results

- Score and undercut the repair boundaries so the cured putty has a “dovetail” mechanical lock.

- Wet a gloved finger or a plastic spreader with a touch of alcohol to smooth the surface before cure.

- Overfill slightly, then plane/sand back rather than trying to get perfectly flush on the first pass.

- For screw repairs, always pre-drill after cure; driving a screw into uncured putty is a recipe for a weak hold.

- Label the purchase date and store the stick sealed in a cool, dry place to maximize shelf life.

Value and who it’s for

KwikWood’s 1 oz, 3.5-inch stick is best for small to medium repairs. If you’re doing large restorations, you’ll go through it quickly, and a bulk epoxy system might be more economical. For homeowners, furniture tinkerers, and jobsite carpenters who routinely encounter chewed-up screw holes, chipped edges, hinge blowouts, and gap-filling odds and ends, it’s an excellent thing to keep in the kit. The blend of speed, strength, and shapeability is the draw here.

Recommendation

I recommend KwikWood for anyone who needs a fast, dependable wood repair putty that sands and drills like the real thing. It sets quickly, bonds well, doesn’t shrink, and takes a finish—especially paint—beautifully. Use it for rebuilding edges, packing hinge mortises, repairing stripped holes (with proper pre-drilling after cure), and filling knot holes or rot voids you’ve cleaned and stabilized. Be mindful of the short working time, plan for pigment or paint if you need color match, and keep fresh stock on hand. Treated that way, it’s a reliable, go-to fix for the kinds of wood repairs that stall projects and blow timelines.

Project Ideas

Business

Mobile wood repair service

Offer on‑site fast repairs for common household wood problems—door/window hinge repair, rot patches, gouge and knot hole fixes. Market as same‑day small repairs that restore function and appearance: quick set time (15–25 min) and full cure in ~1 hour lets you finish a job in a visit. Charge per repair or by time; target property managers, landlords and busy homeowners.

Upcycle & flip small furniture

Buy damaged small furniture, use the epoxy putty to rebuild missing sections, fill gaps and sculpt new details, then sand, stain/paint and resell. Emphasize 'structurally repaired, not just painted' in listings. Low material cost and fast cure time lets you turnaround inventory quickly—scale by batching repairs.

Specialty restoration for collectors

Provide niche restoration services for antiques, picture frames, musical instruments or dollhouses where discrete, non‑shrinking repairs are needed. Promote expertise in color‑matching (staining the putty) and reversible finishes. Charge premium rates for careful, museum‑quality fixes that preserve value.

DIY repair kits + video tutorials

Assemble small consumer kits (1 oz putty stick, mixing tool, mini sanding pad, stain sample and instructions) for common fixes (hinges, knob holes, small gouges). Sell kits online or via local hardware stores and pair with short how‑to videos showing quick cures and finishing tips—monetize via kit sales and ad/sponsorship on tutorials.

Maintenance contracts for rentals

Offer recurring maintenance packages to landlords and short‑term rental hosts focusing on quick, inexpensive wood repairs that keep units rentable (window sills, door edges, cabinet damage). Use the fast‑curing epoxy to do on‑site fixes between guests; price per unit or monthly retainer, highlighting reduced turnover time and avoided replacements.

Creative

Miniature furniture sculpting

Use the hand‑mixable epoxy putty to rebuild broken legs, replace missing chair spindles or sculpt new ornate trim for dollhouse or scale furniture. The putty sets in 15–25 minutes and cures in an hour, so you can rough shape, sand, drill tiny screw holes, and stain the light‑tan surface to match existing wood grain for seamless mini restorations.

Faux inlay and woodgrain art

Fill gaps and carve decorative motifs into a reclaimed board, then stain and burnish to create faux inlay designs. Because KwikWood sands, stains and holds fine detail, you can sculpt raised lettering, floral patterns or geometric seams that read as carved wood once finished—great for wall art, signs or tabletops.

Custom drawer pulls & knobs

Mold and shape ergonomic, custom drawer pulls or cabinet knobs from the putty, tap and thread them if needed, then sand and stain to match cabinetry. For mixed‑media pieces, embed small metal accents or repurposed hardware before curing to create unique functional hardware.

Reclaimed wood seam & knot fill with accents

Repair knot holes, gouges and dry rot in planks and intentionally leave or carve the cured putty into channels for resin, metallic powders or inlays (e.g., crushed shell, glass). Stain the tan epoxy to blend or contrast with wood, producing decorative seams on cutting boards, shelves or rustic furniture.

Weatherproof garden markers & stake repairs

Repair and rebuild wooden garden stakes, plant markers, birdhouse mounts or trellis posts. The putty won't rot, can be tapped or drilled to add hooks, and takes stain for a natural look. Use it to create carved plant labels or mend broken outdoor décor quickly.