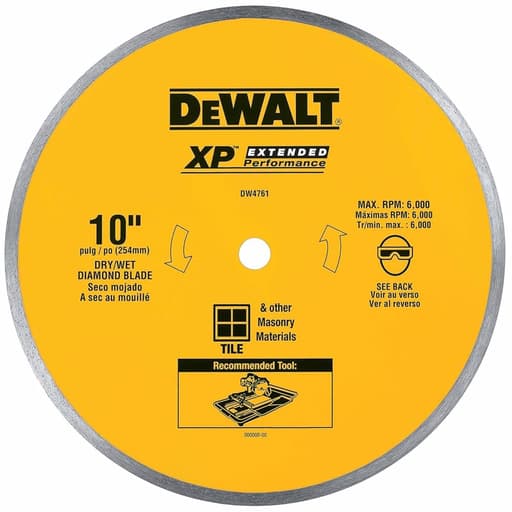

Features

- Extended-performance diamond matrix for longer service life and improved cutting

- Continuous rim for reduced chipping when cutting tile

- Formulated for use with high-power tile saws to maintain straight, low-heat cuts

- Laser-cut expansion slots to reduce blade warping from heat

- Available XP2/XP4 cutting matrices rated by the manufacturer for longer life compared with standard blades (XP2 ≈ 2×, XP4 ≈ 4×)

Specifications

| Arbor Size (In) | 5/8 |

| Number Of Pieces | 1 |

| Product Diameter (In) | 10 |

| Product Pack Quantity | 1 |

| Thickness (In) | 0.08 |

| Wet/Dry | Yes |

| Includes | 1 blade |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

Continuous-rim diamond blade for cutting ceramic tile. Usable wet or dry. The diamond-reinforced edge and matrix are intended to increase service life and cutting performance. Laser-cut expansion slots help reduce heat-related warping during high-power use.

DeWalt 4\" x .060\" Ceramic Tile Blade Wet/Dry Review

Why I reached for this blade

On a recent bath remodel, I swapped in the DeWalt tile blade to see if it could handle a mix of tasks without a bin full of specialty blades. The job included dense porcelain floor tiles, glossy ceramic wall tile, and a marble threshold—plus the usual array of L‑cuts and notches around plumbing. I ran the blade primarily wet on a compact table saw with a standard 5/8-inch arbor, then did a small round of dry trimming on a handheld trim saw to test heat management.

Build and design

This is a continuous‑rim diamond blade formulated for tile. The rim style matters: continuous rims are the go-to for minimizing chip-out on brittle glazes and delicate stones, and this one is paired with an extended‑performance diamond matrix that’s aimed at longer life. The core includes laser‑cut expansion slots to control heat and reduce warping under sustained load. In practice, that combination should translate to straighter cuts with fewer burnt edges when the work runs long or the material runs hard.

Out of the box, my sample was flat and true. Before cutting, I always clean the flanges and snug the arbor nut evenly; a speck of slurry or a ding on the flange is all it takes to introduce wobble. Spun up freehand, the blade tracked straight without a noticeable hum or vibration.

Cut quality: porcelain, ceramic, and stone

Porcelain: The blade did its best work on porcelain. Cross‑cuts on 12x24 tiles were clean and consistent, with only faint micro-chipping that was easy to erase with a dressing stone. Rip cuts stayed straight across the full length, and plunge cuts for electrical boxes had crisp corners when I slowed the entry. I wouldn’t call it a glass‑edge finish, but for a setting that gets grouted, the edge quality was more than acceptable.

Ceramic: Glossy ceramic glazes are less forgiving. Running at a moderate feed, I saw a light sprinkle of edge chipping on the first passes. Two adjustments solved most of it: I increased water flow and switched to a score‑and‑cut technique—one shallow scoring pass, then a full‑depth cut. With that, chip-out dropped considerably. Tape over the cut line helped on a particularly brittle batch of wall tile. If your standard is a showroom‑perfect edge on high‑gloss ceramics, you’ll get there, but it takes a little technique.

Marble: On softer stone, the blade cruised. The marble threshold cut cleanly with no burning and edges that needed only a quick rub with a pad. Continuous rims tend to be gentle on stone, and that matched my results.

Mosaic sheets benefited from a backer board to keep everything supported; with that in place, the blade left clean edges across small tesserae.

Speed, heat, and straightness

Cutting speed sits in the reasonable middle. It’s not a hyper‑aggressive, coarse‑matrix blade, but that’s the trade-off for smooth edges. If I pushed too fast on porcelain, I could feel heat build and see the water steam, which is my cue to ease off. Running wet with steady feed, the blade stayed cool to the touch at the rim, and I didn’t observe any drift or warping over extended cuts. The core’s expansion slots seemed to do their job, keeping the plate stable as the motor worked.

I made a handful of dry notches outdoors just to see how it behaved without water. It handled short, shallow cuts fine, but heat climbed fast on deeper passes. Noise went up, too. I’d keep dry use to light trimming only and save continuous dry cutting for blades specifically designed for it.

Accuracy and feel

Once seated, the blade tracked true. On the tile saw’s sliding tray, it held a line without nudging the tile sideways, which is a good indicator of a rim that’s evenly dressed. L‑cuts were square at the inside corner, with no tendency to hook out at the exit. On miters, slowing the last half‑inch kept the apex tidy.

If you notice a “swimmy” feel or a faint oscillation mark on the cut face, check the basics before blaming the blade: clean flanges, proper torque, and verify the cart and fence are aligned to the blade with a dial or feeler gauge. A new blade can also benefit from a quick dress on a silicon carbide stone to expose fresh diamonds—especially after the first few cuts.

Durability and wear

Across the remodel, the DeWalt tile blade held its edge well. I didn’t log linear feet, but it cut the entire project without a mid‑job swap, and rim wear was uniform with no glazing. The wear rate feels in line with an extended‑performance matrix: conservative enough to protect edge quality, not so hard that it polishes over. If you primarily cut dense porcelain day in and day out, a premium long‑life variant might stretch further, but for mixed residential work, this one sits at a sensible balance of life, speed, and finish.

Noise and vibration

Continuous‑rim blades tend to run smoother than segmented or turbo profiles, and that showed here. With proper water flow, the blade presented a steady, even tone. No harmonic ringing, no chatter. If your saw is prone to resonance, a rubber‑backed washer can help, but I didn’t need one.

Practical tips for best results

- Dress the blade lightly at the start with a dressing stone or scrap paver block to expose sharp diamonds.

- Maximize water flow on porcelain and glossy ceramics; more coolant equals fewer chips and longer life.

- Use a score‑and‑cut approach on fragile glazes: one shallow pass, then the full-depth cut.

- Support mosaics and narrow rips with a backer to prevent vibration at the rim.

- For miters, slow the final inch to protect the apex.

- Keep the tray square to the blade and check for runout; most “wobble” complaints trace back to setup.

Limitations

This isn’t a specialty glass blade, and I wouldn’t pick it for glass tile or ultra‑high‑gloss ceramic where the edge is fully exposed and ungrouted. It can do those cuts in a pinch with careful technique, but a glass‑rated blade will be kinder. For continuous dry cutting, I’d also look for a blade specifically optimized for dry use; while this one is rated wet/dry, it performs best wet.

Value and compatibility

With a standard 5/8-inch arbor, it fits the most common tile saws and compact trim saws I use on site. You get the expected DeWalt fit and finish, the continuous rim for clean edges, and a core designed to hold straight when warm. There’s also the peace of mind of a short money‑back window if it doesn’t suit your saw or material batch.

The bottom line

The DeWalt tile blade earns its keep on mixed tile jobs, especially where porcelain is in the lineup. It balances cut quality, straight tracking, and reasonable life in a way that suits remodelers and serious DIYers alike. It’s not a silver bullet for every tile—glass and mirror‑gloss ceramics still reward a more specialized rim—but with sensible technique and a properly set up saw, it turns out clean, repeatable cuts.

Recommendation: I recommend this blade for general tile work, particularly if porcelain makes up a big part of your project mix. It’s a solid, predictable performer when used wet, and it rewards good technique with clean edges. If your project demands perfect, exposed edges on glass or highly brittle glazed ceramic, consider a purpose‑built glass blade instead. For most bathrooms, kitchens, and floors with standard porcelain and ceramic, this DeWalt strikes a practical, reliable middle ground.

Project Ideas

Business

On-Demand Tile Cutting Service

Offer mobile or shop-based precision tile cutting for DIYers and contractors who lack a saw. The blade’s continuous rim and heat-dissipating slots enable accurate, low-chip straight cuts and miters. Charge per cut or per tile, with rush fees for same-day service.

Custom Mosaic Commissions

Design and install bespoke mosaic murals, table tops, and entryway medallions. Use the blade for clean micro-cuts and tight tolerances that elevate detail work. Sell packaged offerings (small, medium, large panels) and upsell grout color matching and sealing.

Tile Repair and Trim Specialist

Niche service focused on cracked tile replacement, outlet cutouts, and edge trimming around fixtures. The blade’s reduced chipping is ideal for blending new tiles with existing installations. Market to property managers and realtors for quick turnover fixes.

Workshops and Maker Classes

Host beginner-to-intermediate classes on tile cutting, pattern layout, and safe wet/dry techniques. Monetize through tuition, materials kits, and tool add-ons (blade + safety gear bundles). Partner with makerspaces and community colleges for recurring sessions.

E-commerce Tile Decor Shop

Sell handcrafted coasters, trivets, house number plaques, and backsplash feature panels online. Use the blade to maintain consistent edge quality across batches, reducing rejects. Offer customization (colors, fonts, sizes) at premium pricing and leverage made-to-order production to control inventory.

Creative

Mid-century Mosaic Side Table

Cut ceramic tiles into triangles, trapezoids, and thin strips using the continuous-rim blade to minimize chipping. Arrange a sunburst or terrazzo-style pattern on a thrifted side table top, then thinset and grout for a durable, furniture-grade finish. Use wet cuts for long, straight segments and dry for quick trims.

Custom House Numbers Plaque

Cut contrasting tile pieces into crisp numerals and frame segments. The diamond matrix keeps edges clean so numbers look professionally made. Mount on a backer board, add weatherproof grout, and hang by the entry for a bespoke address marker.

Geometric Backsplash Feature Panel

Create a removable art panel for the kitchen by cutting repeating hexagons, chevrons, or herringbone pieces. The blade’s expansion slots help keep long cuts straight. Mount pieces on a plywood backer sealed with waterproof membrane for easy installation and future updates.

Upcycled Planter With Inlay

Break scrap tiles intentionally, then refine edges with the blade to craft consistent shard shapes. Inlay them into a concrete or wooden planter to create a stained-glass look. The continuous rim reduces microchips, resulting in cleaner grout lines in tight curves.

Coaster and Trivet Gift Set

Cut 4" and 6–8" ceramic tiles to size and bevel edges lightly with controlled passes. Add cork backing and assemble color-coordinated sets. Use wet cutting for precise, chip-free edges on visible faces, producing a boutique-quality finish.