Features

- Triple-sharp teeth for smoother cuts

- Control cut shoulders to reduce kickback

- Micrograin carbide tips for impact resistance and longer edge life

- Speed-coat finish to reduce friction and pitch buildup

- Thin kerf for faster cuts and reduced waste

- Hardened steel plate to resist bending and deflection

- Diamond knockout for mounting/removal

Specifications

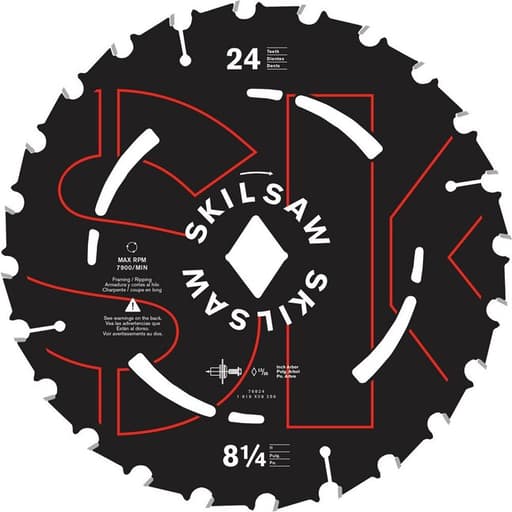

| Diameter | 8-1/4 in |

| Teeth | 24 |

| Kerf | 0.08 in |

| Tooth Material | Micrograin carbide |

| Plate Material | Extra hard (hardened) steel |

| Finish | Speed coat |

| Diamond Knockout | Yes |

Related Tools

Related Articles

Circular framing saw blade with triple-sharp teeth designed for smooth cuts and improved finish. Control cut shoulders reduce kickback. Micrograin carbide tips resist impact and retain sharpness. Speed-coat finish reduces friction and pitch buildup. Thin kerf allows faster cuts and less material waste; the hardened steel plate resists bending and deflection. Includes a diamond knockout for mounting/removal.

Skil 8-1/4 IN. X 24T Framing Saw Blade Review

Why I reached for this blade

I keep an 8-1/4-in worm-drive saw in the truck for framing days and deeper rips, and finding good blades in this size is harder than it should be. I picked up the Skil 8-1/4-in 24T blade for a couple of framing packages and some rough sheet-good breakdown, curious whether its thin kerf, “triple-sharp” tooth geometry, and control shoulders would actually translate into cleaner, faster cuts on a jobsite saw that lives hard.

Short version: it’s a solid, no-fuss framing blade that favors speed and tracking without feeling twitchy, and it holds an edge better than I expected in wet lumber. It doesn’t pretend to be a finish blade, but it punches above its tooth count on crosscuts and leaves less cleanup than a typical 24T.

Setup and compatibility

Out of the package, the blade mounts without drama. It includes a diamond knockout so you can run it on older worm-drive saws that need that style of arbor. If your saw uses a standard 5/8-in round arbor, leave the center intact; if you need the diamond, pop it out and it seats securely. On my worm drive, the fit was tight and true—no eccentric wobble, no shim fuss.

At 0.08 in kerf, it’s notably thin for a blade this diameter. That’s a plus for underpowered saws or long rips where motor load adds up. The plate feels appropriately stiff for a thin-kerf blade, and the hardened steel shows up in how it resists flex when you inevitably bump it during blade changes.

Cutting performance: framing stock

In SPF 2x material, the blade is quick. The aggressive hook and 24 teeth want to move, but the control cut shoulders do a good job preventing the blade from “self-feeding.” I could push steadily without feeling the saw fight me or surge forward when it hit clear grain. That trait matters when you’re toe-boarding a cut or making awkward overhead trims—less chance of the saw jumping if your stance isn’t perfect.

Crosscuts in 2x were cleaner than average for a 24T. The triple-sharp grind leaves a tighter top edge with fewer feathered fibers, especially across knots. End grain looked more like what I’d expect from a decent 30T than a pure ripper. You still won’t mistake it for a finish or trim blade, but for framing layouts where layout lines need to remain visible and plates need to sit flush, it’s a pleasant surprise.

Ripping long studs and plate stock went quickly, and the saw didn’t bog. The thin kerf noticeably reduces load—on my older saw, I can hear the difference in motor pitch compared to a thicker general-purpose blade. That translates into less arm fatigue and cleaner tracking.

Sheet goods and engineered lumber

For rough breakdown of 3/4-in plywood and OSB, tear-out was controlled on the top face, again better than typical for 24 teeth. If I tape the cut line or score the face veneer first, I can get serviceable edges for subfloor and sheathing without reaching for a higher tooth count. On LVL and PSL, it cuts straight and fast, but you’ll see splintering on the exit side; if I’m trimming engineered stock for exposed surfaces, I swap in a 40T.

In wet pressure-treated 2x, the blade stayed lively. The coating seems to help shed resin and water—there’s less drag on restart mid-cut. After a dozen cuts in damp PT, pitch buildup on the teeth was minimal, and a quick wipe-down at the end of the day kept the blade feeling slick.

Tracking, deflection, and finish

Thin-kerf blades can wander under side pressure or when you rush a cut. I tested long rips down the crown of 2x10 with occasional knots. If I forced the feed, I could induce a bit of chatter at knots, but keeping a steady, moderate pace kept the kerf straight. The hardened plate does its job; there’s no telltale warble or harmonic vibration mid-cut, and the saw line doesn’t widen unpredictably.

The cut surfaces show a fine, uniform tooth pattern without deep scoring. For framing, that means plates seat well and studs don’t need touch-ups before nailing. On plywood, the exit side benefits from a zero-clearance base or backing scrap if you care about splinters.

Heat, pitch, and the coating

Skil’s speed-coat finish isn’t marketing fluff here. On resinous pine, I usually see a thin glaze build on the sides of the teeth; after a day of mixed cuts, this blade had faint discoloration but little sticky buildup. That has two benefits: your feed rate stays consistent, and the blade stays quieter because it isn’t rubbing the kerf walls. Cleaning was simple—citrus cleaner, light brush, and it looked nearly new.

Heat management is good. I purposefully ripped several long lengths back-to-back; the plate never blued, and I didn’t feel the need to pause between cuts. That’s not always the case with thin kerf. Credit to the plate temper and grind for keeping the friction under control.

Safety and feel

The control cut shoulders stand out most when starting plunge cuts or trimming ends mid-span where binding tends to happen. The blade engages predictably—no grabbing, no sudden pull. That makes it forgiving when you’re working on a ladder or in cramped spaces. Of course, it won’t prevent kickback from poor technique or pinching stock, but the geometry takes some edge off the “pucker factor” that rougher 24T blades can bring.

Noise is typical for a framing blade, but the tone is smoother, with less metallic chatter. Vibration through the handle is low; I could mark a line and follow it one-handed on lighter rips without fighting the saw.

Edge life and durability

Micrograin carbide tips matter once you’re through the first couple of workdays. After framing a couple of walls, cutting out window and door openings, and breaking down a stack of sheathing, the teeth still felt sharp under a thumbnail test and continued to feed well. I grazed a shallow brad in a reno cut; it left a faint tick on one tooth but no chip-out, and performance didn’t change meaningfully afterward. That aligns with what I’d expect from micrograin carbide—less prone to shattering, more likely to dent slightly than explode when you hit something small.

Long-term, a 24T framing blade will need sharpening sooner than a 40T finish blade if you ask it to do finish work. Kept in its lane—framing lumber, rough sheet, occasional engineered cuts—it holds up admirably. The plate stayed flat, and I didn’t see any tooth solder lines crack, which is sometimes a weak point on budget blades.

Where it fits in my kit

- Fast framing and layout cuts where speed and line accuracy matter

- Subfloor and sheathing when I don’t need furniture-grade edges

- Remodel work in mixed materials where a thin kerf helps an older saw keep pace

I swap it out for:

- Trim and cabinet-grade plywood (40–60T)

- Fiber-cement or metal-laminate (specialty blades)

- Track-saw finish passes (dedicated blade)

Value and availability

In the 8-1/4-in size, choices are limited compared to 7-1/4-in. This blade hits a practical balance of performance and price. You’re paying for a real grind, decent carbide, and a hardened plate without wandering into premium territory. For a daily-driver framing blade, that’s the right spend.

Quirks worth noting

- It’s a true thin-kerf blade. Let the saw do the work and keep a consistent feed to avoid chatter in knotty stock.

- If your saw needs a diamond arbor, confirm before you knockout the center and seat it fully; once it’s out, you’re committed.

- For exposed plywood edges, scoring or a strip of painter’s tape along the cut line reduces tear-out on the exit side.

The bottom line

The Skil 8-1/4-in 24T blade is a dependable framing companion: fast, predictable, and surprisingly clean for its tooth count. The thin kerf makes older and smaller saws feel stronger, the control shoulders keep the saw well-mannered in less-than-ideal positions, and the coating does its part to keep resin at bay. It won’t replace a finish blade for cabinetry or high-visibility trim, but it doesn’t try to. It focuses on getting framing cuts done quickly, straight, and with minimal fuss.

Recommendation: I recommend this blade for anyone running an 8-1/4-in circular saw who needs a reliable, affordable framing option—especially if you use a worm drive that benefits from a diamond knockout. It earns a spot in the rack by balancing speed, control, and edge life, and it’s one of the better-performing choices in an under-served blade size.

Project Ideas

Business

Deck and fence pre-cut service

Offer a mobile service that measures on site and delivers labeled, pre-cut joists, rails, pickets, and blocking ready to assemble. The fast-cutting 24T blade and thin kerf increase throughput and material yield, while the hardened plate keeps cuts square across repetitive production runs.

On-site sheet goods breakdown

Provide panel breakdown for remodelers and designers who lack space or tools. Use a straightedge guide with the 8-1/4 in saw to rip and crosscut plywood, OSB, and MDF to project-ready dimensions. The triple-sharp teeth and speed-coat finish help reduce tear-out and friction for cleaner edges.

Reclaimed lumber prep and resale

Source pallets and barn boards, then de-nail, rip, and square edges into consistent widths for sale as project packs. The blade’s micrograin carbide tips withstand dirty stock, and the thin kerf boosts yield so you can price competitively. Offer curated bundles for wall accents, shelves, and crafts.

Custom raised-bed kits and installs

Sell made-to-order garden bed kits with precisely cut corners, caps, and notched braces, plus optional delivery and installation. The blade’s control cut shoulders reduce kickback on long rips in wet-treated lumber, and the durable plate ensures consistent, repeatable cuts for scalable production.

Stair stringer and rough-opening specialist

Market a niche service cutting stair stringers, headers, and blocking for small contractors. The 8-1/4 in capacity lets you plunge and nibble clean notches in 2x stock, and the thin kerf speeds production. Offer same-day site visits and charge per opening or stringer.

Creative

Kerf-bent plywood lamp

Make a modern lamp or wall sconce by cutting closely spaced kerfs into thin plywood so it bends into a gentle arc. The thin 0.08 in kerf and triple-sharp teeth give smoother, controlled cuts that reduce tear-out when kerfing. Glue in place and finish with a light oil; the blade’s reduced friction helps keep burns to a minimum on tight, repeated cuts.

Modular raised planter boxes

Build sturdy outdoor planters from 2x lumber with clean, repeatable cuts. The 24T carbide tips chew through knots and wet stock, and the hardened plate resists deflection for square corners. Make a set of stackable modules in multiple sizes, then torch or stain for a cohesive garden look.

French cleat storage wall

Create a shop or garage organization system using 45-degree bevel cleats ripped from plywood or 2x stock. The blade’s control cut shoulders help reduce kickback on long bevel rips, and the thin kerf wastes less material across dozens of cleats. Add custom tool holders that can be rearranged anytime.

Reclaimed wood herringbone art

Rip and crosscut pallet or fence boards into uniform strips and assemble a herringbone panel. The micrograin carbide teeth handle embedded knots and the speed-coat helps prevent pitch buildup on reclaimed softwoods. Frame it with mitered edges for a statement wall piece.

Minimalist plywood console table

Break down a sheet of plywood into crisp panels for a simple console table with mitered or butt joints. The thin kerf yields more usable offcuts for a shelf or stretcher, and the blade’s smoother cut reduces sanding time. Edge-band and finish with a clear coat for a clean, modern look.