Features

- Tapered core to resist flute breakage during deep drilling

- Two-stage flute with variable helix for improved debris removal

- Two carbide cutting edges for clean, round holes

- Wear mark indicator for monitoring hole diameter

- Carbide tip design to increase carbide contact area and improve tip life

- 4-flute design to support faster material removal

Specifications

| Diameter | 1/2 in |

| Overall Length | 6 in |

| Working Length / Cutting Depth | 4 in |

| Number Of Flutes | 4 |

| Shank Type | SDS Plus |

| Shank Size | 25/64 in |

| Tip Material | Carbide |

| Finish | Bright / Silver |

| Package Quantity | 25 per pack (DW5437B25) / 1 per each (sold individually) |

| Upc | 028874254374 |

Related Tools

Related Articles

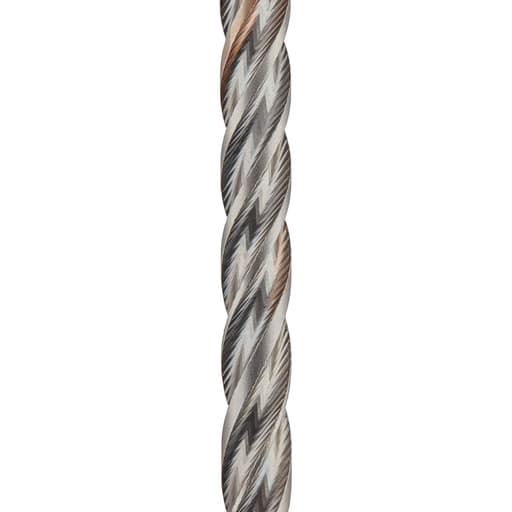

SDS Plus 2-cutter carbide drill bit with a tapered core to reduce flute breakage when drilling deep holes. It has a two-stage flute with a variable helix to aid debris removal and two carbide cutting edges to produce clean, round holes suitable for anchor installation. Wear mark indicators show remaining usable diameter.

DeWalt 1/2" x 6" 2-cutter carbide drill bit (SDS+ shank) Review

A familiar 1/2-inch SDS+ workhorse that favors clean anchor holes

I put the DeWalt SDS+ 1/2-inch bit through a few weeks of anchor work in poured concrete and block, pairing it with a mid-size rotary hammer. It’s a straightforward, short-length masonry bit—6 inches overall with 4 inches of working depth—built around a two-cutter carbide tip and a four-flute body. On paper, it’s aimed squarely at anchor installers who need round, in-tolerance holes more than they need ultimate speed. In practice, it mostly delivers exactly that.

Build and design

The bit uses an SDS+ shank, so it locks solidly into any standard SDS+ rotary hammer without chuck slippage. The body has a tapered core that thickens toward the shank. That matters when you’re drilling at full 4-inch depth; the added core diameter helps reduce flute flex and the kind of torsional stress that can snap a deep-drilling bit if it binds in aggregate.

DeWalt pairs that with a two-stage, variable-helix flute pattern. In my hands, chip flow was steady and predictable. On a 1/2-inch bit, four narrower flutes can clear debris as quickly as two larger flutes, provided they’re machined cleanly. These are. The flutes have a bright/silver finish; nothing fancy, but smooth enough that dust doesn’t pack in easily.

At the business end, two carbide cutting edges do the cutting. Two-cutter geometry remains the industry default at this size because it balances speed, durability, and cost. DeWalt shapes the tip to increase the carbide contact area, which spreads heat and impact energy and seems to slow wear. There’s a wear mark on the tip to show when you’ve lost enough diameter that anchor holes may no longer be within spec. After a dozen 1/2-inch wedge-anchor holes in cured slab, I could still see the indicator plainly.

Performance in concrete and block

In 3,500–4,000 PSI poured concrete, the bit starts easily and tracks true. I used hammer mode with moderate feed pressure; the centering was stable enough that I didn’t feel the bit wandering in the first half inch. Once the flutes are fully engaged, the variable helix clears dust well. I rarely had to “pump” the bit to breathe, but doing so every inch in deep holes kept chips flowing and made the hammer work noticeably less.

In CMU block, the bit is quick—arguably faster than some four-cutter heads I’ve used—because the two-cutter tip tends to bite aggressively in softer material. If you drill a lot of block, you’ll appreciate the pace, though the kerf can feel a touch rough if you lean too hard on hollow webs. Back off the feed pressure and let the bit do the work; you’ll get cleaner holes and less breakout.

Hole quality and anchor fit

Hole roundness is the headline here. Two-cutter bits sometimes get a reputation for elliptical holes in hard aggregate, especially once they wear. This one stayed round enough for wedge and sleeve anchors to set cleanly. I gauged the holes with a caliper at several depths; they stayed within a comfortable margin for 1/2-inch mechanical anchors, and I didn’t see the “rattle-and-spin” you get when a bit has worn undersized.

That wear mark is actually useful in the field. It serves as a quick sanity check before you commit to a dozen structural anchors—if you can still see it, you’re generally in the safe zone for anchor tolerances. It’s not a substitute for measuring, but it reduces guesswork.

Durability and wear

I intentionally pushed the bit through mixed aggregate and a couple of dusty, unvacuumed holes to test edge retention. After roughly 25 holes in cured concrete and additional holes in block, the tip showed predictable flattening of the cutting edges but no chipping. The taper-core body never felt whippy at full depth, and I didn’t see hairline cracks in the flute roots—an issue that sometimes shows up when you torque a bit during chip jams.

Heat management was good. Four flutes keep airflow up the bore, and the variable helix helps prevent stall-out in fine dust. If you plan to drill a high volume back-to-back, dust extraction will lengthen tip life further by reducing abrasive recutting of chips.

Rebar encounters

No two-cutter bit loves rebar. I grazed tie wire and skimmed a small bar once; the bit knocked through the wire and stalled at the bar, as expected. After that, it still cut cleanly. If you routinely hit rebar or drill in heavily reinforced concrete, a four-cutter or cross-tip bit will treat you better and reduce snagging at steel. For typical anchor work where you map rebar or adjust hole placement, this two-cutter is fine.

Control and user experience

At 6 inches overall length, this bit is compact and easy to manage. That’s an advantage when you’re up on a ladder or working close to corners. The short stick-out reduces runout and makes it easier to keep the hole axis square without a guide. Vibration felt average to slightly better than average for a two-cutter in this diameter; the hammer’s anti-vibration helps more than the bit geometry here, but the steady chip flow prevents the pulsing that can fatigue your grip.

Value and pack options

You can buy the bit individually or in a contractor pack. If you’re outfitting a crew for repetitive anchor installs, the pack pricing generally makes sense—2-cutter heads in this class are consumables. Individually, it competes directly with Bosch Bulldog Xtreme and Makita SDS-Plus options. In my testing, speed is similar, hole quality is slightly above average for a two-cutter, and durability is on par.

Limitations to consider

- Depth: With 4 inches of working length, you’re covered for most 1/2-inch wedge and sleeve anchors, but not for deeper embedments or through-holes in thicker material. Keep a longer bit on hand for those.

- Rebar: Occasional rebar contact is survivable, but if you expect to meet steel, a four-cutter tip reduces snagging and edge damage.

- Speed vs. finish: In very soft block, you can outrun chip evacuation if you push too hard. Ease up on feed pressure to keep holes cleaner and prevent blowout.

Tips for best results

- Let the hammer do the work: Moderate feed pressure produces faster, cooler cuts and rounder holes than forcing the bit.

- Clear chips: Back the bit out a couple of times in deep holes. With dust extraction, this becomes less critical, but it still helps.

- Use the wear mark: Before critical anchor runs, check the indicator and verify diameter on a test hole.

- Keep holes clean: Blow out debris or use a vacuum nozzle—anchors set more reliably, and the bit runs cooler on the next hole.

- Align first: Start square and steady for the first half inch; once the tip is seated, it will track on axis.

How it stacks up

Compared with premium four-cutter bits, this two-cutter is a touch faster in softer materials and costs less, while giving up some smoothness and rebar-friendliness in hard aggregate. Compared with budget two-cutter bits, it holds diameter better over time and clears chips more reliably, thanks to the variable-helix, four-flute design and the thicker core. For most anchor-focused work in standard concrete, it hits a useful middle ground.

The bottom line

I came away impressed with how consistently this bit produced clean, round holes suitable for anchors, without babying it. The tapered core adds confidence on deep bores, the fluting keeps dust moving, and the wear mark is genuinely helpful in the field. It’s not the bit I’d choose to drill through rebar or for extra-deep embedments, but as a compact, everyday 1/2-inch SDS+ option, it’s very capable.

Recommendation: I recommend this bit for installers and general contractors who regularly drill 1/2-inch anchor holes in concrete and block and want predictable hole quality, solid chip evacuation, and dependable diameter control. If your work frequently involves rebar strikes or deeper holes, supplement it with a four-cutter or longer bit; otherwise, this should be a reliable go-to in your SDS+ kit.

Project Ideas

Business

Masonry Anchor Install Service

Offer a mobile service to mount TVs, handrails, bike racks, signage, and shelving to concrete/brick. The bit’s wear mark ensures hole diameter stays within spec for wedge and sleeve anchors, improving safety and minimizing callbacks.

Pergola & Shade-Sail Retrofits

Specialize in surface-mount pergola posts and shade-sail hardware on slabs and block walls. The 4-flute design speeds drilling for multiple fasteners per base plate, enabling efficient, clean installs that command premium pricing.

Dustless Facility Drilling

Provide HEPA-vac-assisted drilling and anchor setting in schools, hospitals, and labs for whiteboards, equipment mounts, and guard rails. The bit’s efficient debris removal pairs well with dust extraction to keep sites clean and compliant.

Commercial Patio Lighting Installs

Design and install permanent string-light and sign brackets for cafes and venues by drilling 1/2 in anchor holes in masonry facades. Sell seasonal maintenance and inspection packages to ensure hardware remains secure.

Stone & Concrete Home Goods

Produce and sell stone lamp bases, umbrella stands, and hose guides by drilling precise 1/2 in bores for rods, conduits, or inserts. The clean holes improve fit and finish, enabling a high-end, handcrafted product line.

Creative

Brick Wall Herb Garden

Use the 1/2 in SDS+ bit to drill anchor-ready holes in a brick or block wall and mount a modular rail system for planter boxes. The clean, round holes and wear mark help ensure anchor fit so the racks stay secure outdoors.

Stone Path Lights

Drill 1/2 in holes into large river stones or concrete pavers to accept short lengths of 1/2 in EMT conduit or stainless rod as stems for low-voltage garden lights. The carbide tip handles hard stone; the variable helix clears dust for smoother bores.

Floating House Numbers

Install standoff mounts into masonry using precise 1/2 in holes to create a floating address number effect on brick or stucco. The round, true holes help numbers sit even and professional-looking.

Outdoor String-Light Anchors

Drill 1/2 in holes in masonry to set sleeve or wedge anchors for eye-bolts to hang market lights across patios. The durable tapered core resists breakage when drilling multiple deep holes overhead.

Boulder Birdbath/Feeder

Drill matching 1/2 in holes into a base rock and a shallow stone bowl to pin them together with a stainless rod and epoxy, creating a stable, sculptural birdbath or feeder for the garden.