Features

- Aluminum oxide abrasive for general-purpose metal cutting

- Thin wheel profile to reduce burr and secondary processing

- Two layers of fiberglass reinforcement to improve wheel strength and reduce breakage

- Flat disc design suitable for use on compatible angle grinders and cut-off tools

- Intended for a variety of metal applications (pipe, tube, sheet, plate, rebar, etc.)

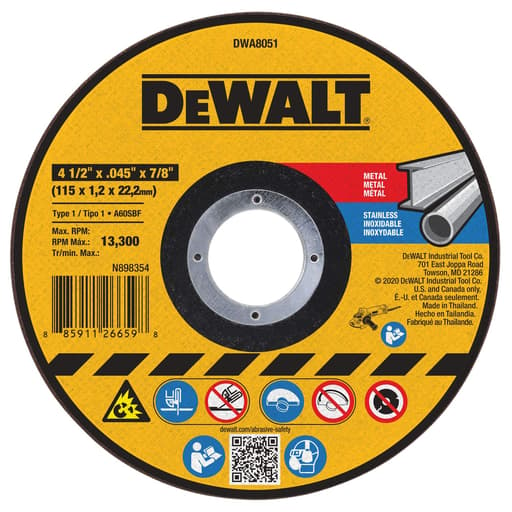

Specifications

| Product Diameter | 4.5 in (4-1/2 in) |

| Disc Thickness | 0.045 in (.045) |

| Arbor Size | 7/8 in |

| Disc Type | Flat (cut-off wheel) |

| Abrasive | Aluminum oxide |

| Reinforcement | Two sheets of fiberglass |

| Pack Quantity | 25 per box |

| Intended Applications | Steel; stainless steel; angle iron; rebar; pipe; tube; structural sheet; sheet metal; thick plate; heavy wall pipe |

| Warranty | |

| California Prop 65 Warning | Yes |

Related Tools

Related Articles

Thin cut-off wheels with aluminum oxide abrasive designed for cutting a range of metal materials. The thin profile reduces burrs for less secondary finishing. Wheels are reinforced with two layers of fiberglass for increased strength and to help limit wheel breakage.

DeWalt General Purpose Cutting Wheels Review

First impressions and setup

Pulling a fresh 4-1/2 inch cut-off wheel out of a 25-pack is a small pleasure in a metal shop. The DeWalt wheel hits the sweet spot for general-purpose cutting: thin at 0.045 inch, flat Type 1 profile, and a standard 7/8-inch arbor that fits most handheld grinders and cut-off tools. It’s an aluminum oxide wheel, reinforced with two layers of fiberglass, so it’s built for everyday steel work without the premium price or specificity of ceramic or zirconia options.

I ran this wheel across a mix of jobs: trimming mild steel tube and angle, sizing rebar on-site, slicing through sheet and plate, and making a few careful cuts in 304 stainless. I mounted it on a compact 4-1/2 inch grinder with the factory guard and a standard flange set. No shims, no adapters—just a straightforward install and a true-running disc.

Design that prioritizes cut quality

At 0.045 inch, the wheel’s thin kerf is its defining characteristic. That narrow profile brings two big benefits:

- Less material removal: faster plunges and less heat.

- Reduced burr formation: less time chasing edges with a flap disc.

The flat Type 1 shape excels at straight cuts and plunge cuts. It tracks well if you score and guide the cut, and the thinness lets you work with a light touch. The two fiberglass layers aren’t just marketing—on thin wheels, reinforcement matters. I was able to cut confidently without worrying about edge crumbling, provided I kept side loads in check.

Cutting performance on common steels

For shop staples—angle iron, light plate, and tubing—the DeWalt wheel is a solid performer. It bites quickly, throws a predictable spark stream, and doesn’t chatter or resist once the cut is established. In 16-gauge tube and angle, kerfs stayed narrow and square, and the line didn’t wander as long as I scored a shallow groove before committing to full depth. Rebar (which can be gummy and uneven) was similarly manageable; the wheel held a straight path and resisted glazing as long as I kept pressure moderate.

On thicker plate, the benefits of the thin kerf are still there, but technique becomes more important. For stock around 1/4 inch and up, I found it helpful to take a shallow pass or two to keep the path straight, then let the wheel work the depth rather than forcing it. With a light feed, the cut stayed cooler and the wheel wore evenly.

Stainless and heat management

Stainless always tests a wheel’s balance of aggressiveness and heat control. The DeWalt wheel handled 304 without drama. It cut cleanly and, with light pressure, didn’t overheat the edge or discolor excessively. That said, specialized “inox” wheels typically run cooler and resist loading on stainless; if you’re doing continuous stainless production work, those are still my go-to. For occasional stainless jobs, this wheel is absolutely serviceable.

A quick note on contamination: if your stainless work is sensitive (sanitary or aesthetic), keep a dedicated wheel for stainless to avoid embedding carbon steel dust into the cut surface.

What it’s not for

This is a metal-cutting wheel. If you need to cut tile, brick, mortar, or most masonry, use a diamond or silicon carbide wheel designed for those materials. I tried a quick, cautious pass on a ceramic tile offcut to confirm; as expected, the aluminum oxide bond wore quickly and the edge chipped. Wrong tool for the job.

The same goes for nonferrous metals like aluminum. Aluminum tends to load and glaze aluminum oxide wheels. You can get by in a pinch with a dedicated nonferrous wheel and lubricant, but I don’t recommend using this one for that. Keep it on steel and stainless, where it shines.

Durability and wheel life

Thin wheels are always a trade-off: cut speed and finish against rigidity and life. For its thickness, this DeWalt wheel holds up well. The two-layer reinforcement helps the disc survive minor mishandling and interrupted cuts without edge crumbling, and I had no issues with warping or premature cracking. I retired wheels when they reached a diameter where guard coverage and cut stability started to drop—normal practice for thin cut-offs.

Compared with premium ceramic abrasives, this wheel won’t last as long on heavy cross-sections or hard alloys, but that’s expected given the abrasive type. In return, it offers a clean, fast cut on everyday steels with predictable wear, and the 25-pack format makes it easy to keep the shop stocked and costs in check.

Cut quality and cleanup

The key promise of a 0.045-inch wheel is less burr and less post-processing. In mild steel sheet and tube, I consistently had minimal burr. A light pass with a deburring tool or quick touch with a flap disc was all that was needed. On thicker stock or when the cut wasn’t perfectly straight, burrs were more noticeable, but still less aggressive than what you’d see from a thicker, more aggressive wheel.

If you’re cutting to a scribe line, this wheel’s thin kerf and low lateral drag make it easy to stay on mark. Score lightly, then deepen the cut. That approach prevents the wheel from walking and reduces the chance of binding.

Safety and handling

A few practical notes from use:

- Use the guard. Thin wheels can shatter if side-loaded; the guard is non-negotiable.

- Let the wheel do the work. Excess pressure overheats the bond, increases burr, and shortens life.

- Keep cuts straight. Cut-off wheels aren’t for grinding; avoid twisting in the kerf.

- PPE matters. Sparks and dust are real; wear eye, ear, gloves, and a respirator as appropriate.

- Store wheels flat and dry. Bonded wheels can absorb moisture and have a shelf life—check the disc’s date code.

- Observe the disc’s labeled maximum RPM. Don’t exceed it.

- Note the Prop 65 warning and manage dust and ventilation accordingly.

Fit-wise, the 7/8-inch arbor is standard. If you’re using an X-Lock grinder, confirm compatibility; many accept conventional 7/8-inch discs, but not all.

Where this wheel fits best

- Fabrication and repair where you’re cutting mild steel tube, angle, sheet, and plate up to moderate thickness.

- Site work that involves rebar and general steel stock.

- Occasional stainless cuts where you want a clean line without switching to a dedicated inox spec.

- Shops that benefit from the consistency and convenience of a 25-pack.

If you regularly cut thick plate, heavy wall pipe, or you’re cutting stainless all day, consider supplementing with a thicker wheel (0.060 inch) for stability or a ceramic-grain wheel for longer life and cooler performance.

Tips for better results

- Score first, then commit to full depth to keep cuts straight.

- Clamp the work and support both sides of the cut line to prevent pinching.

- Make relief cuts on long or heavy sections to prevent the kerf from closing.

- Use fresh wheels for stainless to minimize contamination.

- Retire the wheel before it gets too small to be safely guarded.

The bottom line

The DeWalt wheel is a straightforward, reliable thin cut-off option for everyday metalwork. It cuts fast, leaves a cleaner edge than thicker wheels, and holds up respectably for a 0.045-inch aluminum oxide disc. The reinforcement inspires confidence without inviting misuse, and the 25-pack keeps downtime to a minimum.

Recommendation: I recommend this wheel for general-purpose metal cutting on steel and occasional stainless. It’s a practical, dependable choice when you want a thin kerf, low burr, and predictable behavior on a standard 4-1/2 inch grinder. I wouldn’t choose it for masonry, aluminum, or heavy, continuous stainless production—that’s better served by task-specific wheels—but as a daily driver in a metal shop or on a jobsite, it earns a place on the shelf.

Project Ideas

Business

Mobile On-Site Cutting Service

Offer jobsite cutting of steel pipe, rebar, angle iron, and sheet using an angle grinder and these reinforced wheels. Target small contractors and DIYers who need quick, accurate cuts without hauling material. The thin wheels reduce burrs, cutting down your time on edge cleanup and increasing daily throughput.

Custom Metal Signage & House Numbers

Produce house numbers, nameplates, and simple logo signage from steel or stainless sheet. Use careful layout with templates and relief cuts for curves, then finish with brushing, paint, or powder coat. Sell via local markets and online, offering custom sizes and mounting hardware.

Flat-Pack Furniture & Bracket Kits

Precut steel for coffee table bases, shelf brackets, planter frames, and bench legs. Bundle with hardware and finishing instructions, leveraging the clean edges from thin-kerf cuts to reduce customer prep. Sell as DIY kits to makers and interior designers seeking industrial-style accents.

Rebar Fabrication for Landscapers

Cut rebar to spec for edging pins, garden hoops, trellises, and form stakes. Offer bulk pricing and quick turnaround to landscapers and concrete crews. The fiberglass-reinforced wheels hold up for high-volume cutting, keeping your costs predictable.

Trailer and Farm Gate Modification Service

Provide on-site cutting and resizing of steel gates, fence panels, trailer rails, and utility racks. The general-purpose aluminum oxide abrasive handles common steels found in agricultural hardware. Pair with basic welding and drilling services for a full small-fab solution.

Creative

Geometric Metal Wall Art Panels

Use sheet steel or stainless to cut geometric patterns and negative-space designs. The thin 0.045 in wheels minimize burrs, so you’ll spend less time dressing edges before painting or clear-coating. Make multiple panels that tile together, or backlight them with LED strips. Add small relief cuts to handle curves safely with a flat cut-off wheel.

Rebar Garden Trellis & Sculptures

Cut rebar into lengths for trellises, tomato cages, and abstract garden forms. The reinforced wheels handle repeated cuts without frequent breakage, perfect for batch work. Weld or tie pieces together and finish with rust-inhibiting paint for a rugged, industrial look.

Industrial Pipe Shelving Brackets

Slice heavy-wall steel pipe into spacers and cut flat plate into L-shaped brackets. The thin kerf leaves cleaner edges that require minimal filing before drilling and mounting. Pair with reclaimed wood shelves for a modern-industrial aesthetic.

Custom Firewood Rack

Cut angle iron and flat bar to create a modular firewood stand sized for your space. Straight, accurate cuts with reduced burrs speed up assembly and welding. Finish in high-heat paint or powder coat to match interior or patio decor.

Stainless Tube Wind Chimes

Cut stainless tube to tuned lengths for rich tones and smooth edges. The thin profile helps produce clean, square cuts so chimes hang evenly and look professional. Deburr lightly, polish, and hang with braided wire for a durable, weather-ready piece.