Features

- One-handed trigger operation

- Reinforced nylon body

- Heat-treated I‑beam steel bar

- Up to 600 lb (270 kg) clamping force

- 3-3/4 in (95 mm) throat depth

- Quick-change button for spreader function

- Removable non-marring jaw pads

- Quick-release mechanism

- Safety stop

- Spreading function

Specifications

| Bar Length Mm | 1500 |

| Bar Material | Black oxide carbon steel I-beam |

| Bar Thickness Mm | 7 |

| Body Material | Plastic (reinforced nylon) |

| Clamping Capacity Mm | 1290 |

| Clamping Force Kg | 270 |

| Clamping Force Lbs | 600 |

| Sustained Clamping Force Kg | 270 |

| Throat Depth In | 3-3/4 |

| Throat Depth Mm | 95 |

| Jaw Depth Mm | 90 |

| Jaw Width Mm | 40 |

| Max Jaw Opening Mm | 1290 |

| Spreading Capacity Mm | 1485 |

| Product Length Mm | 1500 |

| Product Width Mm | 270 |

| Product Height Mm | 45 |

| Product Weight G | 2300 |

| Product Weight Kg | 2.3 |

| Number Of Pieces | 1 |

| Packaging | Hang tag |

| Warranty | 1 Year Limited Warranty |

Related Tools

Related Articles

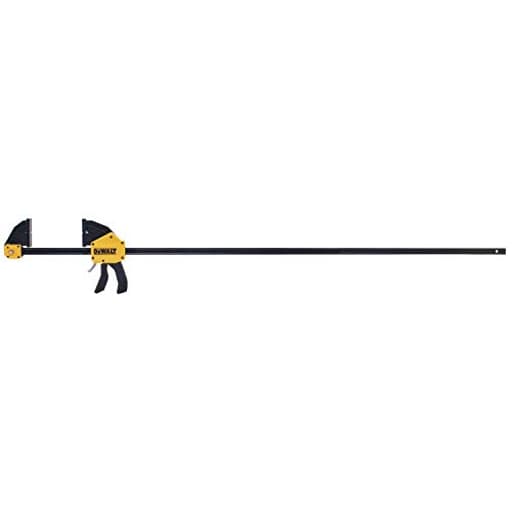

50-inch extra-large one-handed trigger clamp with a reinforced nylon body and heat-treated I-beam steel bar. Provides up to 600 lb (270 kg) clamping force, a 3-3/4 in (95 mm) throat depth, a quick-change button to convert to a spreader, and removable non-marring jaw pads.

DeWalt 50 in. (1250 mm) Extra Large Trigger Clamp Review

First impressions

A 50-inch bar clamp is overkill—until it isn’t. The first time I reached for this DeWalt 50-inch clamp, it was because nothing else could bridge a wide span while giving me one-handed control. It’s a niche size for sure, but once you’re working across joists, door frames, long torsion boxes, or awkward spans where a pipe clamp won’t fit or a parallel clamp is too short, the utility becomes obvious.

Build and design

The clamp combines a reinforced nylon body with a heat-treated I‑beam steel bar. The bar is black-oxide coated, resists rust reasonably well, and the I‑beam profile adds stiffness without too much weight. At about 2.3 kg (roughly 5 lb), it’s balanced for its size—still hefty, but manageable one-handed when you’re in a ladder or reaching over framing.

The jaws ride smoothly on the bar and include removable, non-marring pads. The pads have enough give to protect finished faces and painted trim, but they’re firm enough to transmit pressure into construction lumber without squirming. The throat depth is 3-3/4 in. That’s generous for a trigger clamp and gives some flexibility when you’re stepping around moldings or trying to grab past a small lip, though it’s still shallow compared to parallel clamps.

A quick-change button flips the tool into a spreader. The conversion is quick and tool-free, and the safety stop keeps the head from sliding off the bar while you’re switching modes.

Clamping performance

DeWalt rates this clamp at up to 600 lb of force. I don’t test with a load cell in the shop, but in use it feels stronger than the typical “HD” trigger clamps and well suited to structural tasks: pinching a twisted 2x into line, holding a stair stringer tight while you fasten, or locking long 1x stock against a ledger. The ratcheting trigger stacks pressure predictably, and the quick-release lever bleeds pressure with control rather than springing open.

Across most of its range, clamping is solid. At full extension you’ll see some bar deflection—expected on a 50-in clamp under real load. On softwoods I never ran short of power. On harder woods, you’ll still get the bite you want, but as with any trigger clamp, it’s not a substitute for a screw clamp when you need sustained maximum pressure for edge-gluing dense hardwood.

A few practical notes from the shop:

- Keep the bar clean. Fine dust and pitch buildup can reduce bite and make the pawl slip under high load. A wipe with mineral spirits now and then helps.

- Don’t oil the bar. Lubricant can make the mechanism too slick and encourage slippage.

- Pre-seat the jaws by hand, then ratchet. You’ll get more uniform pressure and less tendency for the jaws to creep on smooth surfaces.

Spreader function

Converted to a spreader, the clamp reaches up to about 58 in. I use it for dry-fitting pocket door frames, opening bowed casing before fastening, and pressing deck boards apart to swap a spacer. In spread mode, deflection is more noticeable at the longest setting, so accuracy demands a lighter touch. Within a few feet of spread, though, it’s predictable and much faster than futzing with a screw jack or handmade wedge.

Ergonomics and control

The handle contour is comfortable, and the trigger arc builds pressure without overextending your wrist. One-handed operation is genuinely useful at this size. I routinely hold stock with a free hand, position the fixed jaw with my hip or forearm, and tighten with the trigger—something I can’t do with long screw clamps.

Weight is the tradeoff. Holding the clamp overhead for long runs will fatigue your forearm, especially in repeated clamping cycles. For tasks like clamping ledger boards above shoulder height, I set a temporary support or use a secondary, lighter clamp to stage the piece, then bring in this clamp to lock it down.

Accuracy and deflection

On assemblies that require straightness—like bringing two sheet goods into co-planarity—I check with a straightedge once it’s under pressure. The bar remains acceptably straight for most construction tasks, but under heavy force at full span it can bow a few millimeters. If you’re gluing up cabinets and need dead-straight clamping across long edges, a parallel clamp or a pipe clamp pair may be a better choice. For framing, subfloors, or temporary positioning, the 50-inch clamp is more than adequate.

Durability and maintenance

The bar’s finish holds up well against scratches and incidental knocks. The reinforced body hasn’t shown cracks or stress whitening in normal use. The wear point to watch is the clutch mechanism. On any trigger clamp, dust and resin can build around the pawl and toothed rail; when that happens, high loads can cause the jaw to creep. A simple maintenance routine has kept mine reliable:

- Wipe the bar and teeth periodically.

- Pop off the pads and clear debris from the contact surfaces.

- Inspect the quick-change button; if grit gets in, it can feel gummy and prevent full engagement.

- Store the clamp with light tension released to avoid long-term compression of the pawl spring.

The pads are removable and replaceable, which is good because large-span clamps see a lot of edge contact. I haven’t had the pads pop off during use, but if you twist the clamp while under load, you can shift a pad slightly—realign before the next squeeze to prevent denting a surface.

Where it shines

- Long-span positioning: Pulling 2x members into alignment across wide bays, holding fascia or ledger boards, and staging long rips on the bench.

- Temporary platforms and jigs: Building a cantilevered working surface or extending an outfeed with 1x stock clamped to sawhorses.

- Door and frame work: Drawing jambs square and holding casings while you nail, especially with the spreader function.

- Decking and fencing: Nudging boards together or apart where a smaller clamp can’t reach from reference to edge.

Limitations

- Throat depth: At 3-3/4 in, you’re not reaching deep into assemblies. If you need to clamp past a thick face frame or a wide lip, plan for blocks or consider a different clamp style.

- Weight and bulk: In tight interiors or ceiling spaces, the long bar can snag and the weight will tire your arm. For repetitive overhead work, mix in lighter clamps for staging.

- Ultimate pressure: Despite the strong rating, trigger clamps aren’t the best tool for high-pressure glue-ups in hardwood. They’re champions of speed and convenience, not maximum PSI.

Value and warranty

This clamp sits above entry-level options in both size and capability, and that’s reflected in its price category. What you get is speed, reach, and enough force to handle structural tasks a smaller trigger clamp can’t. The 1-year limited warranty is basic but typical for a hand tool of this type. For longevity, care matters more than coverage—keep the mechanism clean and it should serve well.

Tips for better results

- Use sacrificial cauls or blocks to broaden contact on soft materials.

- If you need parallel pressure, pair two clamps opposite each other to balance bar flex.

- In spreader mode, increase pressure gradually and check alignment frequently; long spreads amplify small errors.

- Label your clamps by length; grabbing the 50-inch when you only need 24 inches is fatigue waiting to happen.

Recommendation

I recommend this 50-inch clamp for carpenters, remodelers, and builders who routinely work across wide spans, as well as for woodworkers who need a fast, one-handed solution for large assemblies. It delivers strong, predictable clamping with genuinely useful reach, the spreader function is quick to deploy, and the ergonomics are good for a tool of its size. Keep the bar and mechanism clean, respect its limits compared to screw or parallel clamps, and it will become a reliable problem-solver when standard clamps come up short. If your work rarely exceeds 24–36 inches, it’s more clamp than you need; otherwise, it’s an effective, time-saving addition to the rack.

Project Ideas

Business

Mobile Glue-Up and Flattening Service

Offer on-site panel/tabletop glue-ups for DIYers and contractors who lack large clamps. The 50 in capacity and 600 lb force handle doors, countertops, and dining tables; one-handed triggers speed setup in tight spaces. Upsell alignment cauls, router-sled flattening, and finish sanding. Bill per inch of glue line plus travel.

Pop-Up Canvas Stretching & Framing

Run a booth for artists/galleries to stretch, square, and frame oversized canvases on demand. Use the spreader mode to pre-tension canvas and clamp mode to hold miters while pinning or gluing. Non-marring pads protect delicate frames. Offer tiered pricing for standard vs. archival materials.

Door and Frame Re-Squaring Service

Specialize in racked doors and out-of-square jambs. Use the clamp as a diagonal spreader or clamp to bring frames back into square, then secure with shims/screws. The high clamping force corrects twist while the pads avoid finish damage. Package with hinge tune-ups and weatherstrip replacement.

Big Clamp Rental Kits for Makers

Rent sets of extra-large trigger clamps with cauls, corner blocks, and pad covers for weekend builds. Deliver locally and include quick guides for tabletops, doors, and laminations. Charge a flat weekend rate plus deposit; add-on fees for consumables and same-day delivery. Great for makerspaces and small shops.

Bent-Laminate Product Line

Produce small-batch goods—curved floor lamps, wall-mounted arches, longboards—using the clamps for reliable, repeatable laminations. The quick-change spreader function speeds mold release and reloading, boosting throughput. Sell direct online and at markets; offer custom sizes/colors. Position as lightweight, strong, and sustainably glued.

Creative

Wide-Panel Dining Table Glue-Up

Edge-join 4–6 boards into a tabletop using alternating top/bottom clamp placement to keep the panel flat. The 50 in opening spans most table widths, while 600 lb clamping force eliminates glue-line gaps. Add straight cauls near the edges and lightly clamp them with the trigger clamps to prevent cupping; the non-marring pads protect the wood. Quick-release makes cleanup and repositioning fast between glue-ups.

Bent-Laminated Arch Floor Lamp

Build a plywood bending form and laminate thin wood strips into a graceful arch. Use multiple trigger clamps along the form; the 600 lb force per clamp gives even pressure for crisp glue lines. After cure, hit the quick-change button to convert to spreaders and gently open the form to release the piece without prying. Finish with a routed channel for LED strip lighting.

Longboard/Skateboard Deck Press

Create a two-part mold (convex/concave) for veneer or maple laminations and press with several 50 in clamps spaced along the deck. The I-beam bar resists flex so pressure stays uniform, and non-marring pads prevent denting. Use the spreader mode to pre-load or release the mold safely. Shape, sand, and grip for custom boards.

Canvas Stretcher and Framing Station

Build a modular stretcher-frame jig sized up to 50 in and use the clamp’s spreader function to tension canvas evenly before stapling. The one-handed trigger lets you hold the canvas with your other hand, and the pads keep frames pristine. Swap to clamp mode to square corners and hold miters tight while glue sets. Perfect for large-format art.

Live-Edge River Table Assembly

Clamp two live-edge slabs to straight cauls to align edges and flatten twist before pouring resin. The 3-3/4 in throat depth and 600 lb force pull stubborn boards into plane without crushing bark thanks to the non-marring pads. Use spreaders to push bowed slab edges into parallel alignment around your mold. After cure, clamp straightedges for router-sled flattening passes.