Features

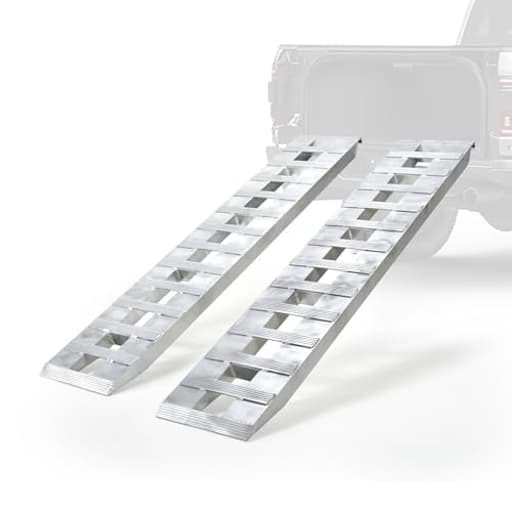

- ∮LIGHTWEIGHT MATERIALS - HEAVYWEIGHT CONSTRUCTION∮-Our 10,000Lbs loading ramps are designed for heavy-duty use on the job site but built with your back muscles in mind. Made from corrosion-free marine grade alloy they are incredibly durable while remaining lightweight at only 32Lbs per ramp.

- ∮MAXIMUM TRACTION FOR SKID STEER, RUBBER TRACKS OR TYRES∮-Our Aluminium Loading Ramps are designed with all-weather traction in mind. The serrated rungs provide maximum traction for rubber wheels or tracks, making these the perfect ramp for loading skid steer, rubber track machinery, or vehicles in all conditions.

- ∮Secure Loading & Unloading∮-The hook end design secures to the angle iron or rub rail of your trailer to prevent slipping during use so you can easily load heavy equipment into the back of your trailer. Raised slope texture and feet achieve non-slip function to make you carry more stable and safety.

- ∮Optimal Dimensions∮-Each loading ramp measures 6 feet in length, 14 inches in width, and 3.2 inches in thickness, providing ample space and stability. These aluminum ramps are suited for various vehicles, making them versatile utility trailer ramps. Minimum Deck Height: 15", Maximum Deck Height: 36"

- ∮Usage Guidelines∮-Not recommended for trucks with mounted cranes, forklifts, or steel track vehicles. Never exceed the maximum axle capacity of this ramp system.The best way to determine your vehicles axle weight is to drive the heaviest axle of the vehicle on a scale. Normally the front end of the truck is the heaviest axle weight because of the engine.

- ∮Versatile Use∮-The trailer Ramps can be used as a ramp for two-wheeled vehicles such as motorcycles and bicycles, or four-wheeled vehicles such as ATVs, UTVs, pickups, all-terrain vehicles, off-road vehicles, and lawn mowers.

Specifications

| Color | Silver |

| Size | 72" x 14" |

| Unit Count | 1 |

Related Tools

These 72" x 14" aluminum loading ramps are made from marine‑grade alloy, measure 3.2" thick, weigh about 32 lb each, and are rated for up to 10,000 lb capacity. Serrated cross rungs provide traction for rubber tires and tracks, and a hooked end with raised texture and feet helps secure the ramp to a trailer; they suit motorcycles, ATVs/UTVs, lawn mowers and similar vehicles for deck heights of approximately 15"–36", but are not recommended for mounted cranes, forklifts, or steel‑track vehicles.

ONECHOI 72" x 14" Aluminum Ramps, 10000 LBS Capacity, Heavy-Duty Ramps with Serrated Cross Rungs for Maximum Traction, Universal Loading Ramp for Motorcycle, Tractor, ATV/UTV, Trucks, Lawn Mower, 2PCS Review

A lightweight pair of workhorse ramps I can actually carry

I’ve hauled equipment long enough to dread the moment I have to fish out a pair of steel ramps. The ONECHOI 6‑ft aluminum ramps finally broke that cycle for me. At about 32 lb per ramp, I can grab one in each hand, walk them over, and be loading in under a minute. They’re compact at 72 inches long and 14 inches wide, with a 3.2-inch profile that slides easily under a trailer or along a bed rail. Despite the low weight, they’re rated to 10,000 lb (per pair) and built from a marine‑grade aluminum alloy that resists corrosion and shrugs off wet, muddy days.

Below is how they’ve performed across a few months of use moving a compact tractor, a skid steer on rubber, and the usual assortment of ATVs and mowers.

Setup, fit, and security

The top end uses a hooked lip that sits over a trailer’s angle iron or rub rail. On my equipment trailer, the hooks seat cleanly and flat, with full contact along the edge. There’s enough bite that the ramps don’t skate when the tires first meet the rungs. I still add redundancy. These ramps don’t come with integrated retainer pins, so I run a short ratchet strap or chain from each ramp to a stake pocket or D‑ring. It’s a simple upgrade that keeps things locked down and should be standard practice with any removable ramps.

At ground level, the feet have a textured “shoe” that grabs gravel and asphalt well. On smooth, sealed concrete they’re fine, but if you’re loading in a slick shop, placing a short strip of rubber stall mat or a thin anti‑skid pad under the feet makes them feel glued down. The 6‑ft length works for deck heights between roughly 15 and 36 inches; if you’re consistently loading at the taller end of that range, the angle gets steeper than I like for low‑clearance equipment. As a quick reference, with a 24-inch deck height the approach angle is about 18 degrees; at 36 inches it’s about 27 degrees. For very low mowers or compact tractors with long implements, you may want 7–8 ft ramps to reduce the chance of scraping.

Build quality and stiffness

The welds on my set are clean and consistent, and the extrusions are straight. There’s some flex under load—as there should be—but no bounce that makes you clench your jaw halfway up. Under a compact tractor with loader and backhoe attached (roughly 6,000 lb total, with the front axle bearing more), the deflection was predictable and well within what I expect from a ramp this size. The pair stays aligned when loading a skid steer, which can be punishing because of the abrupt weight transfer as you crest onto the deck.

The 14‑inch width is generous and confidence‑boosting for larger tires. It also gives you just enough lateral wiggle room to correct a slightly off‑center line without feeling like you’re walking a tightrope. The rungs are serrated and open, which provides excellent drainage and mud shedding.

Traction in real conditions

Traction is where these ramps earn their keep. The serrated cross rungs bite rubber very well, even when the treads are caked with clay or grass. I’ve loaded in the rain without the “hop and slip” drama you get on flat bar or smooth‑stamped steel. Rubber tracks are also served well by the toothy rungs.

A couple practical notes:

- For very small hard wheels (think narrow casters or tiny dolly tires), the rung spacing isn’t ideal. These ramps are intended for vehicles—ATVs, UTVs, mowers, tractors, and skid steers—not furniture dollies or pallet jacks.

- If you run steel tracks, these aren’t for you, and forklifts are a no‑go. The manufacturer explicitly excludes those, and it’s the right call.

The loading experience

Compared to my old steel pair (about 80–85 lb each), setup is dramatically faster. I’m not wrestling a clumsy, greasy mass; I’m positioning lightweight, balanced pieces that don’t shred my back. That matters when you’re making several trips in a day. The open rungs drain fast, so you’re not carrying a bucket of water each time you move them after a storm.

On the trailer, the hook end feels secure, but I do think the design could benefit from a pair of factory-drilled retainer holes for quick pinning. As-is, the hook seats well and the feet bite the ground, and with a short safety strap there’s effectively no risk of kick-out. I’d also love to see a slightly more aggressive radius on the ground end to keep full contact on uneven terrain. On gravel, they sit flat; on crowned concrete, I noticed a slight teeter before weight is applied, which disappears as soon as a tire hits the first rung.

Capacity and safety

The 10,000 lb rating is generous for a pair of 6‑footers, but like any ramp system, the governing number is the axle load. If your front axle carries 60% of the machine’s weight, that’s what the ramps experience first. I verify axle weight at a truck scale when I’m squarely near the limits. Most compact tractors, UTVs, and mid-size skid steers on rubber will be comfortably within spec, but be honest about attachments and cargo. Never try to “creep” beyond the rating to save a second trip.

With heavy equipment, spacing and alignment matter. I like to mark the trailer deck with paint for the ramp centers that match my machine’s track width. This avoids last‑second fiddling on uneven ground. One more tip: keep the ramp surfaces clean. The serrations don’t help if every rung is filled with wet clay.

Portability and storage

At 72 x 14 x 3.2 inches, the pair stacks neatly. I store them on a shelf in the shop and transport them on the trailer’s side rails when not using the under‑deck trays. The low weight makes overhead storage practical, which wasn’t the case with my steel ramps. The aluminum holds up to road spray and brine; I rinse them occasionally and they still look new. No rust streaks on the trailer, no flaking paint.

What I like

- Strong, predictable stiffness with real-world loads

- Excellent traction from serrated rungs in wet and muddy conditions

- Truly manageable weight for one‑person setup and teardown

- Clean welds and straight extrusions; no racking under lateral loads

- Hook end fits common trailer lip/rub rail profiles

What could be better

- No integrated retainer pin holes; I use straps, but pins would be faster

- Ground-end geometry could sit flatter on crowned or very smooth surfaces

- Six feet is a good compromise, but if you routinely load at 30–36 inches, an 8‑ft option would be friendlier for low-clearance equipment

Who these ramps are for

- Landscapers, property owners, and contractors loading ATVs, UTVs, mowers, compact tractors, and rubber‑tired or rubber‑tracked skid steers

- Anyone replacing heavy steel ramps who wants similar or higher capacity without the backache

- Users with deck heights in the 15–30 inch sweet spot who value traction and portability

Who should look elsewhere:

- Forklift operators, steel‑track machines, and trucks with mounted cranes (explicitly not recommended)

- Operators with very low‑clearance machines and a tall deck height who might be better served by 7–8 ft ramps

Maintenance and longevity

There isn’t much to do beyond periodic inspection. Check welds, look for hairline cracks after hard impacts, and make sure the hook ends stay square. If you use them in winter, rinse brine and check for galvanic corrosion if they live against dissimilar metals. The serrations can be sharp; a quick pass with a brush gets rid of packed mud, and a hose finishes the job.

Bottom line

The ONECHOI 6‑ft aluminum ramps hit a sweet spot: they’re genuinely portable, confidence‑inspiring under load, and versatile across the machines most of us actually haul. The traction is excellent, and the build feels like it will outlast a few trailers. I would like to see factory pin provisions and a slightly flatter foot on crowned concrete, but those are small knocks against a pair of ramps that have improved my workflow more than any other “small” trailer upgrade in the last year.

Recommendation: I recommend these ramps. They combine high real‑world capacity, secure footing, and one‑person portability at a reasonable size. If your typical deck height stays under 30 inches and your machines ride on rubber, these will make loading safer, faster, and easier on your back. Add a simple safety strap for redundancy, keep them clean, and they should serve reliably for years.

Project Ideas

Business

Short‑term Ramp Rental Service

Start a local rental service supplying ramps to homeowners, landscapers, and small contractors who need heavy‑duty ramps for single jobs (moving ATVs, mowers, equipment). Offer delivery/pickup and short‑term insurance. Market via classifieds, FB Marketplace, and local equipment rental directories.

Branded Ramp Modifications & Accessories

Sell value‑added accessories and retrofit packages: padded wheel chocks, winch mounting plates, foldable side rails, edge protectors for trailers, and custom length extensions. Provide installation and safety certification. This increases margin versus selling raw ramps and creates recurring accessory revenue.

On‑site Loading Service for Dealerships & Events

Offer on‑demand loading/unloading crews with certified ramps for motorcycle dealers, auction houses, race teams, and event organizers. Combine labor, ramps, and transport liability into a single service package. Contracts with seasonal events and dealerships yield steady B2B income.

Content & Affiliate Business — How‑To Channel

Create a YouTube/Instagram channel focused on equipment loading, ramp safety, and DIY ramp projects using these aluminum ramps. Produce tutorial videos, product comparisons, and retrofit guides. Monetize via ads, affiliate links to ramps and accessories, sponsored content, and downloadable safety checklists.

Subscription Fleet Service for Landscapers

Offer a subscription model for landscaping and small construction firms: provide a set number of ramps on a monthly basis, deliver to job sites, handle maintenance and replacements. Position it as cost‑effective vs. buying multiple ramps and include priority support for peak seasons.

Creative

Portable Motorcycle Display Stand

Use one ramp as an angled showroom plinth for motorcycle photos or events. Secure the hooked end to a low platform, add removable chocks or wheel straps to the serrated rungs, and mount a lightweight LED strip along the edge. The marine‑grade aluminum gives an industrial look and withstands outdoor shows and photoshoots.

Fold‑away Garage Workbench/Loader

Build a hinged garage bench where the ramp serves dual purpose: when folded down it's a low loading ramp for lawnmowers/ATVs into a trailer or van; when folded up it becomes a rugged workbench top with serrated texture for grip. Add quick‑release pins and rubber feet to protect the shop floor.

Raised Garden Trellis & Path Bridge

Repurpose a single ramp as a raised garden bridge or trellis backer in wet yards. Lay it across planters to create an elevated walkway, or mount vertically as an industrial trellis for climbing vines. The serrated rungs provide attachment points for plant ties and drainage, and the corrosion‑resistant alloy suits outdoor use.

Mobile Pet & Accessibility Ramp

Convert the ramp into a portable pet/elderly accessibility ramp by adding foam padding covers, a foldable side rail, and non‑slip end blocks for home thresholds. The lightweight 32 lb construction makes it easy to carry between vehicles or around the house while retaining heavy‑duty capacity for larger pets or mobility equipment (observe weight limits).

Event Staging & Photo Angle Rig

Use paired ramps as adjustable angle staging for action photography or small pop‑up events. Set them as chocks to tilt ATVs/motorcycles for dynamic shots, or clamp a plywood platform across two ramps to create a temporary elevated stage. The serrated surface helps keep vehicles stable during shoots.